Seed suction disk with rapid transforming holes and seeder

A technology of rapid change and seed suction trays, applied in the agricultural field, can solve the problems of high manufacturing cost, time-consuming and troublesome operation of replacing the seed suction trays, and achieve the effect of convenient operation, simple structure and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

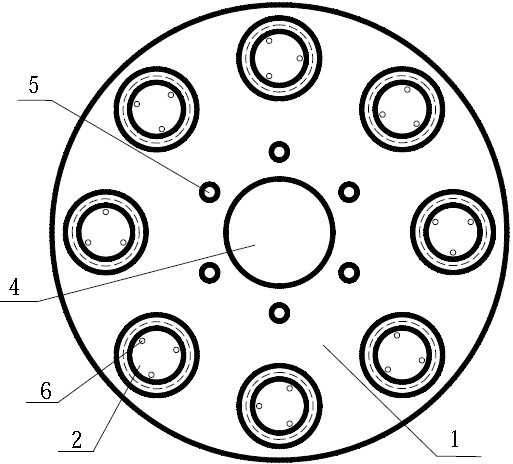

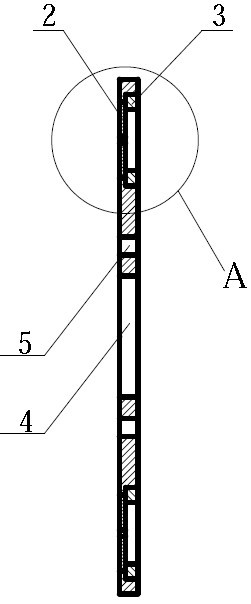

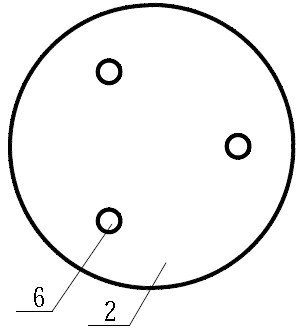

[0023] Such as Figure 1-3 As shown, it is a schematic diagram of the structure of the quick-changing hole seed suction plate of the present invention, including a plate body 1 and a plurality of seed suction holes 6, the center of the plate body 1 is provided with a central through hole 4, and the periphery of the central through hole 4 is provided with mounting holes 5. Eight first counterbores are provided on the periphery of the installation hole 5 near the negative pressure chamber of the seeder, and eight second counterbores coaxial with the first counterbore are provided at the corresponding positions near the seed filling chamber. The bottoms of the first counterbore and the second counterbore communicate with each other, and the bottom surfaces are all planes parallel to the side of the disk body. The diameter of the first counterbore is larger than that of the second counterbore, and both the first counterbore and the second counterbore are circular. The depth of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com