A kind of liquid magnesium treatment process for ship plate steel

A treatment process and technology for ship plate steel, applied in the field of liquid magnesium treatment process of ship plate steel, can solve the problems of industrialized technology integration and application that have not been reported, and achieve improved stability, improved working environment, and improved mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of molten magnesium treatment process of ship plate steel, as follows:

[0032] First, determine the location and timing of magnesium treatment:

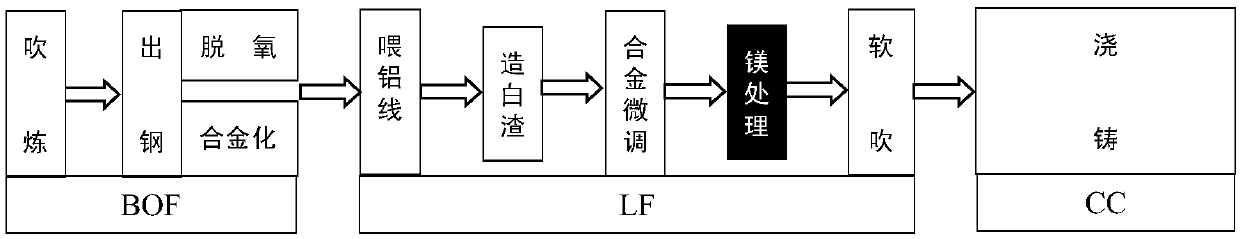

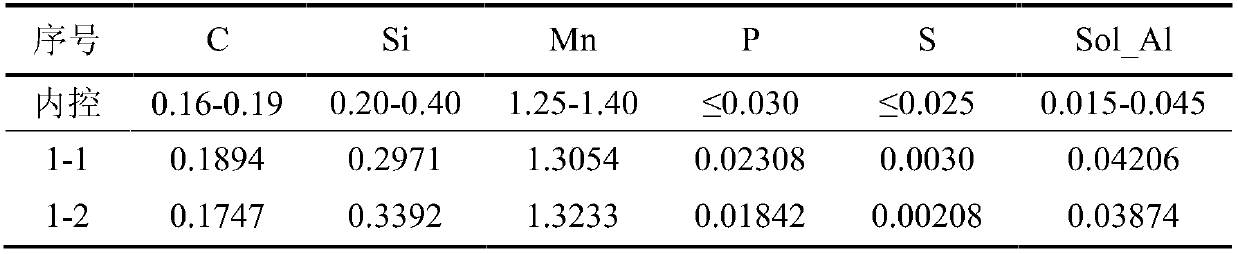

[0033]The steel type relied on in this example is Q345B steel, the smelting process route adopted by this steel type is BOF-LF-CC, and the industrial production of two heats has been carried out; the nominal capacity of the converter is 150 tons, and the Mg-Al-Fe alloy The wire feeding operation of the cored wire is carried out after the fine-tuning of the LF alloy is completed; the composition and mass percentage of the Mg-Al-Fe alloy are: Mg: 5.32%, Al: 52.61%, Fe: 41.70%, and the balance is carbon silicon manganese Impurities such as phosphorus and sulfur; Mg-Al-Fe alloy cored wire parameters are: diameter Φ13mm, iron sheet thickness 0.42mm, core powder particle size 0.01-3mm, core powder filling rate 0.25kg / m;

[0034] BOF-LF-CC route magnesium treatment process such as figure 1 shown;

[0035] Secondly, determi...

Embodiment 2

[0045] A kind of molten magnesium treatment process of ship plate steel, as follows:

[0046] First, determine the location and timing of magnesium treatment:

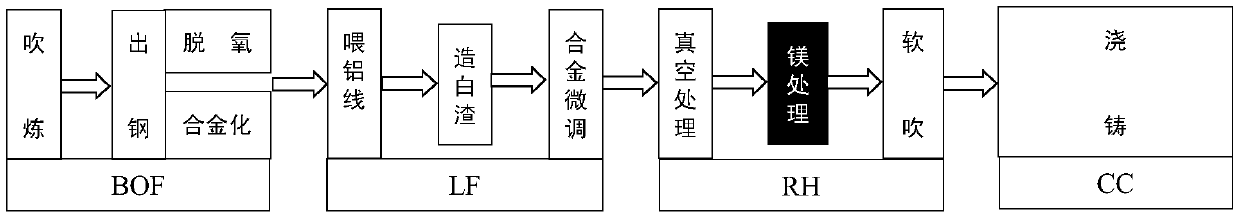

[0047] The steel type used in this example is AH32 steel, the smelting process route adopted by this steel type is BOF-LF-RH-CC, industrial production of two heats has been carried out, the nominal capacity of the converter is 150 tons, Mg-Al- Fe alloy cored wire operations are all carried out after RH vacuum treatment; the composition and mass percentage of Mg-Al-Fe alloy are: 10.18% Mg, 54.87% Al, 34.71% Fe, and the balance is carbon, silicon, manganese, phosphorus, sulfur and other impurities ;The parameters of Mg-Al-Fe alloy cored wire are: diameter Φ13mm, iron sheet thickness 0.42mm, core powder particle size 0.01-3mm, core powder filling rate 0.25kg / m;

[0048] BOF-LF-RH-CC route magnesium treatment process such as figure 2 shown;

[0049] Secondly, determine the amount of aluminum and magnesium treatment fee...

Embodiment 3

[0059] A kind of molten magnesium treatment process of ship plate steel, as follows:

[0060] First, determine the location and timing of magnesium treatment:

[0061] The steel type used in this example is DH36 steel, the smelting process route adopted by this steel type is BOF-LF-RH-CC, industrial production of 5 heats has been carried out, the nominal capacity of the converter is 150 tons, and the magnesium treatment feeding line The operations are all carried out after RH vacuum treatment; the composition and mass percentage of the Mg-Al-Fe alloy are: Mg: 8.24%, Al: 56.47%, Fe: 35.23%, and the balance is impurities such as carbon, silicon, manganese, phosphorus, and sulfur; Mg -Al-Fe alloy cored wire parameters are: diameter Φ13mm, iron sheet thickness 0.42mm, core powder particle size 0.01~3mm, core powder filling rate 0.24kg / m;

[0062] BOF-LF-RH-CC route magnesium treatment process such as figure 2 shown;

[0063] Secondly, determine the amount of aluminum and magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com