Cold-rolled silicon steel convexity and wedge shape dynamic setting control method

A control method, a technology of cold rolling silicon steel, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problem of low control precision of strip steel transverse thickness uniformity, and achieve the effect of solving low control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

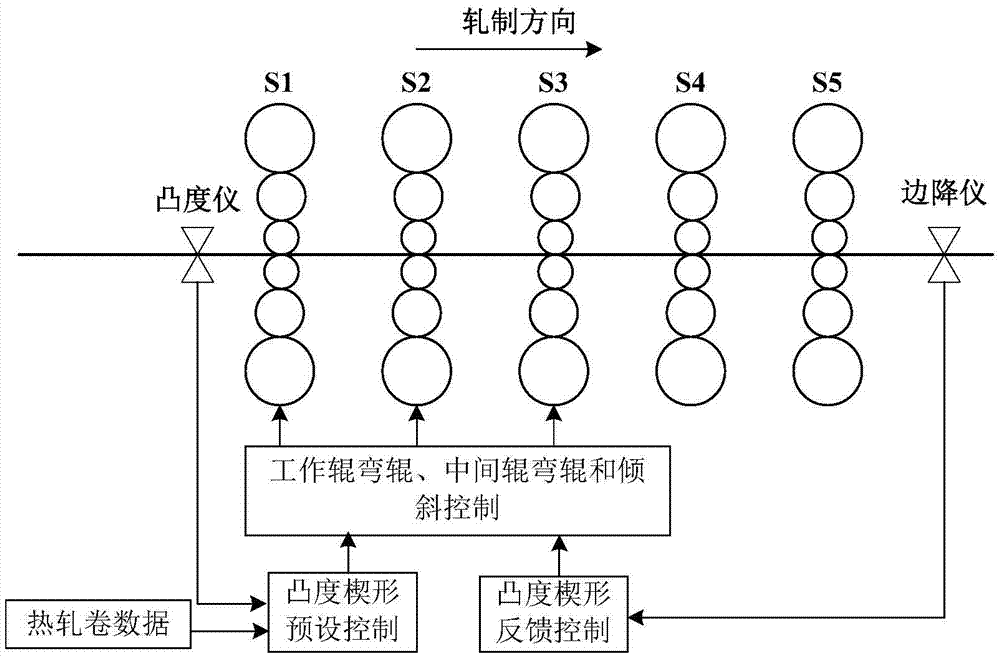

[0065] like figure 1 As shown, it is a schematic diagram of the control principle of the convexity wedge setting according to the present invention. The cold-rolled silicon steel crown wedge dynamic setting control method of the present invention comprises the following steps:

[0066] 1) Establish a preset control model of convexity and wedge shape;

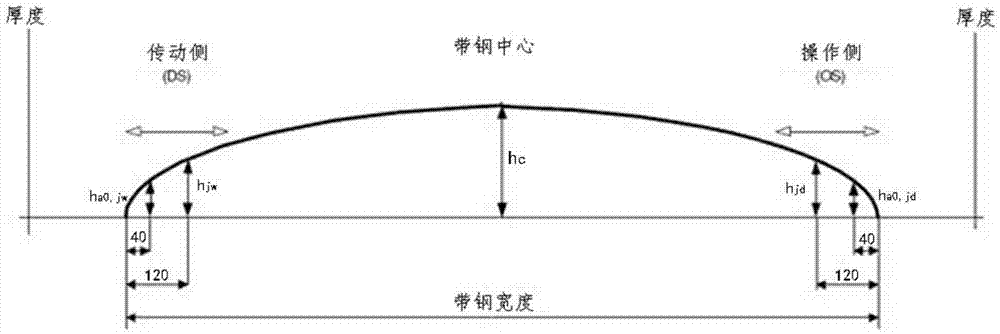

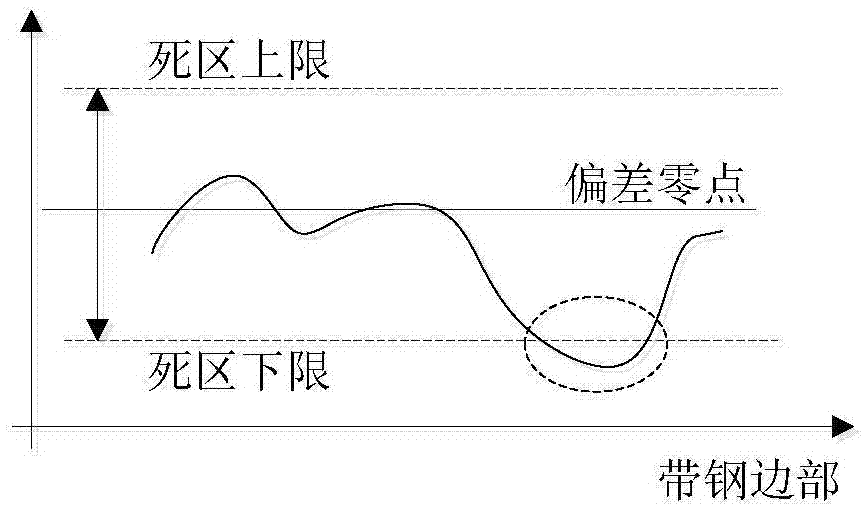

[0067] Judging whether the actual deviation is within the dead zone according to the online detection results of the crown at the entrance of the rolling mill, if it is within the range, do not adjust, otherwise, adjust it; the trigger conditions for crown and wedge setting control are the first stand S1 inlet crown meter After the actual measurement of the S1 entry section data in the steady state rolling state, the calculation is performed based on the measured crown and wedge data of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com