Method for fast preparing lamellate potassium titanate

A kind of potassium titanate, layered technology, applied in the field of preparing layered potassium titanate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Step 1 Melt and mix, take the reactant of potassium stearate and butyl titanate with a potassium-titanium molar ratio of 1:2: 16.13g potassium stearate and 34.03g butyl titanate; add butyl titanate to the molten state In the potassium stearate, add 60g of stearic acid as a solvent to ensure uniform mixing, and the heating and stirring time is 0.5h; if the reactant exceeds 200g, do not add stearic acid solvent.

[0019] Step 2 Combustion in an electric furnace, put the mixture obtained in step 1 into a beaker, place it on an electric furnace with a power of 1kW, heat it to the ignition point, and burn for 2h.

[0020] Step 3: Roasting. The electric furnace combustion product in step 2 is fully ground, put into a muffle furnace, and heated to 750°C at a heating rate of 15°C / min for roasting to obtain layered potassium titanate.

[0021] The resulting layered potassium titanate has the molecular formula K 2 Ti 4 o 9 .

Embodiment 2

[0023] Step 1 Melt and mix, the reactant of potassium stearate and butyl titanate with a potassium-titanium molar ratio of 1:2: 16.13g potassium stearate and 34.03g butyl titanate; add butyl titanate to the molten state In the potassium stearate, add 60g of stearic acid as a solvent to ensure uniform mixing, and the heating and stirring time is 0.5h; if the reactant exceeds 200g, do not add stearic acid solvent.

[0024] Step 2 Combustion in an electric furnace, put the mixture obtained in step 1 into a beaker, place it on an electric furnace with a power of 1kW, heat it to the ignition point, and burn for 2h.

[0025] Step 3 roasting, fully grind the electric furnace combustion product in step 2, put it into a muffle furnace, heat it to 800 °C at a heating rate of 15 °C / min and roast for 2.5 hours to obtain layered potassium titanate.

[0026] The resulting layered potassium titanate has the molecular formula K 2 Ti 4 o 9 .

Embodiment 3

[0028] Step 1 Melt and mix, the reactant of potassium stearate and butyl titanate with a potassium-titanium molar ratio of 1:2: 170.15 g of butyl titanate is added to 80.65 g; butyl titanate is added to the molten stearin Potassium acid, the heating and stirring time is 0.5h.

[0029] Step 2 Combustion in an electric furnace, put the mixture obtained in step 1 into a beaker, place it on an electric furnace with a power of 1kW, heat it to the ignition point, and burn for 2h;

[0030] Step 3 roasting, fully grind the electric furnace combustion product in step 2, put it into a muffle furnace, heat it to 800 °C at a heating rate of 15 °C / min and roast for 2.5 hours to obtain layered potassium titanate.

[0031] The resulting layered potassium titanate has the molecular formula K 2 Ti 4 o 9 .

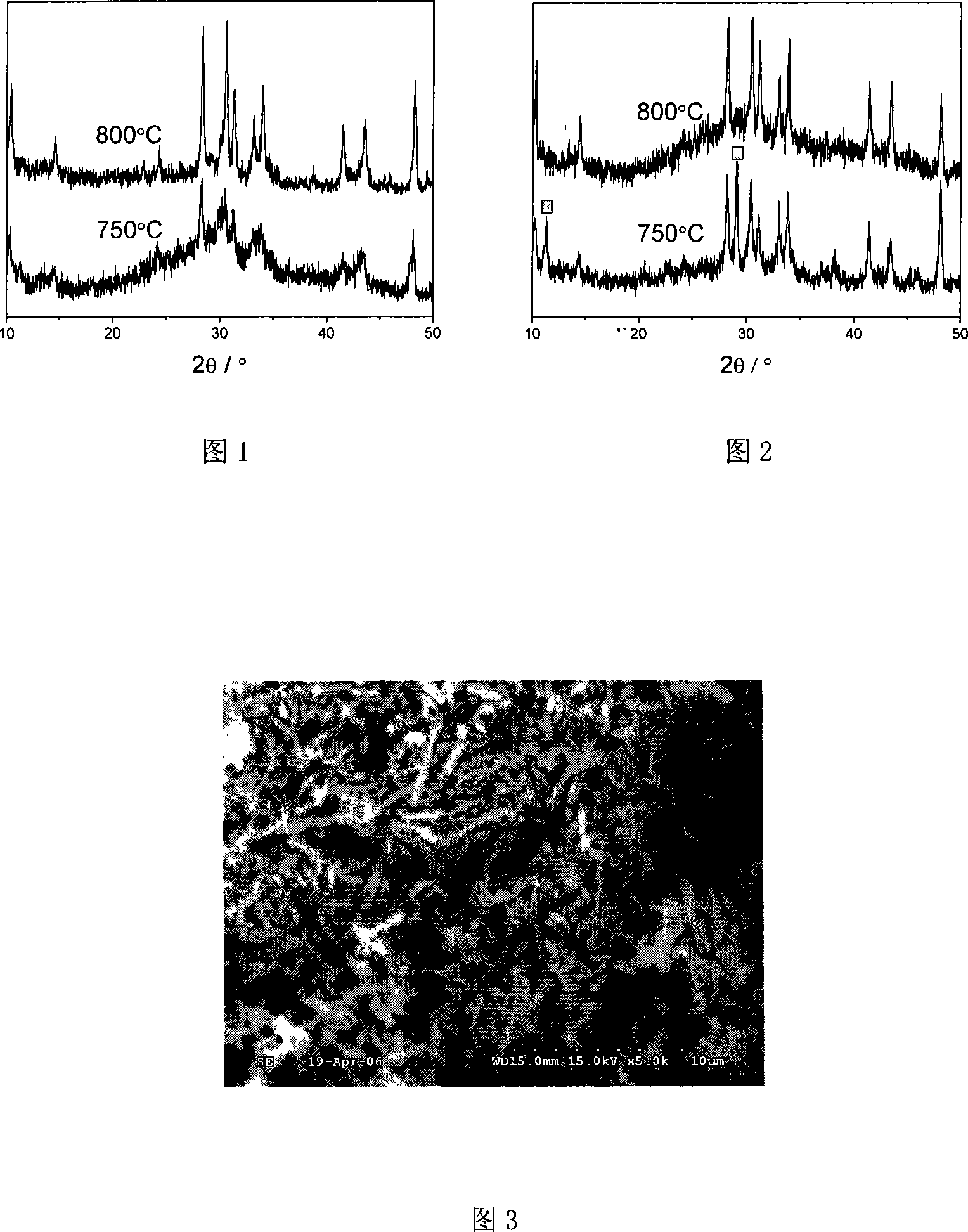

[0032] Fig. 1 is the X-ray diffraction pattern of the product obtained by this method at the calcination temperature of 750°C and 800°C. It can be clearly seen that no other intermedia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com