Recycling method for aluminum in aluminum alloy chemical milling waste liquid

A recovery method and aluminum alloy technology, which is applied in the field of recovery and recycling of aluminum alloy alkaline chemical milling waste liquid, can solve the problems of low production efficiency, poor economic benefit, low purity, etc., and achieve small equipment requirements and low production process Short, pure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

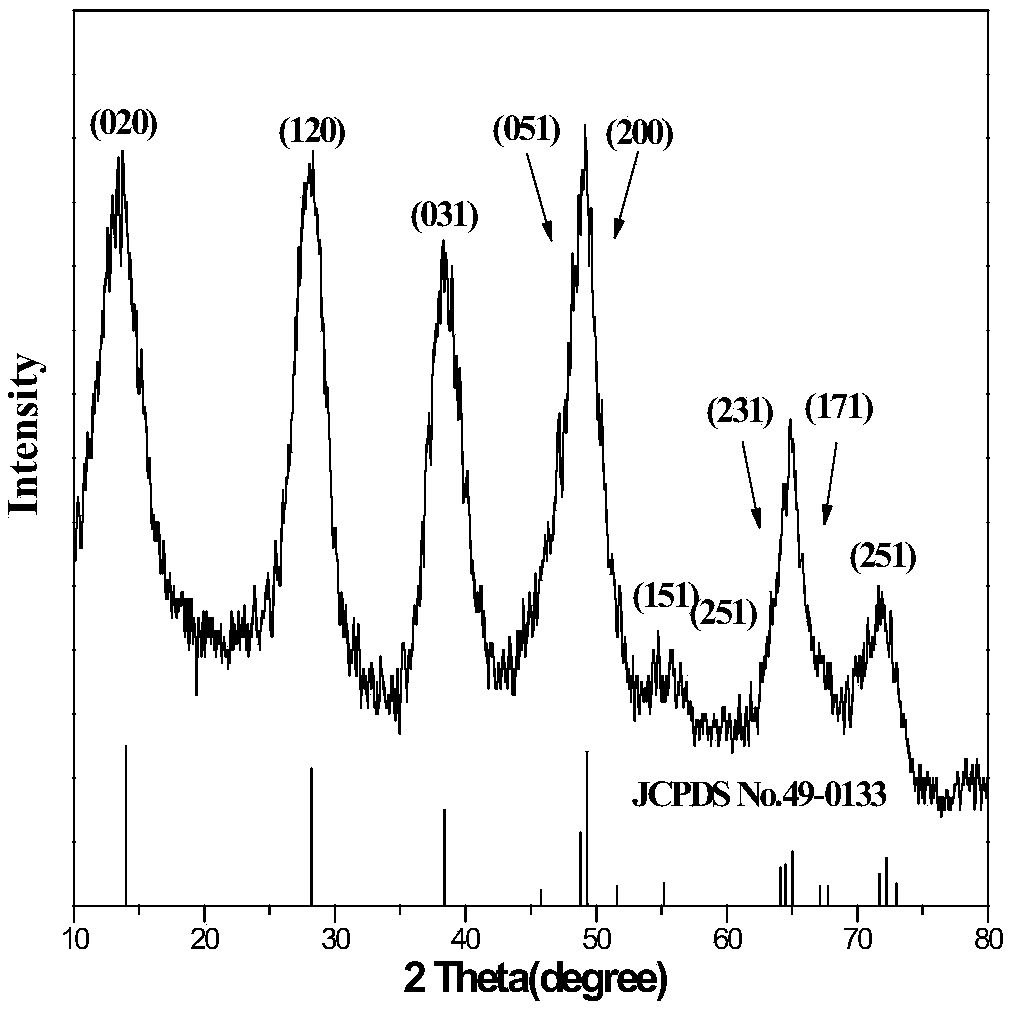

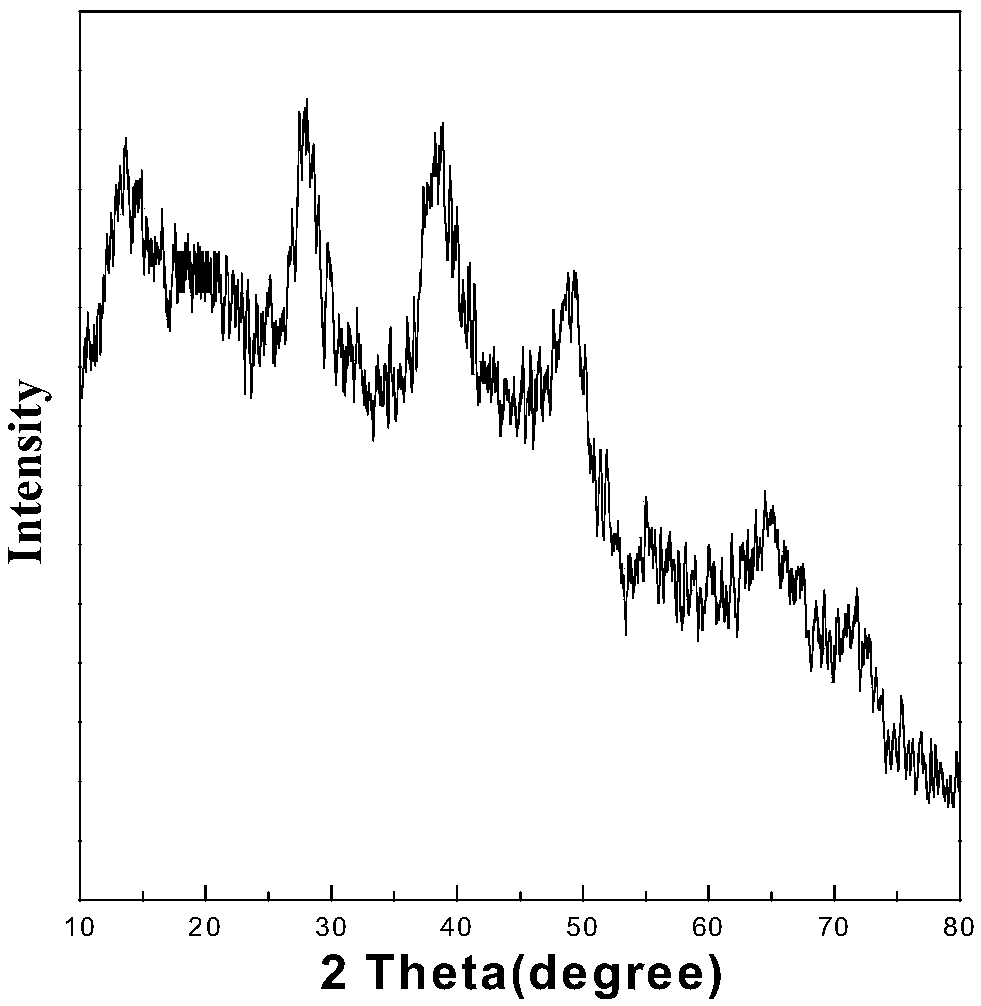

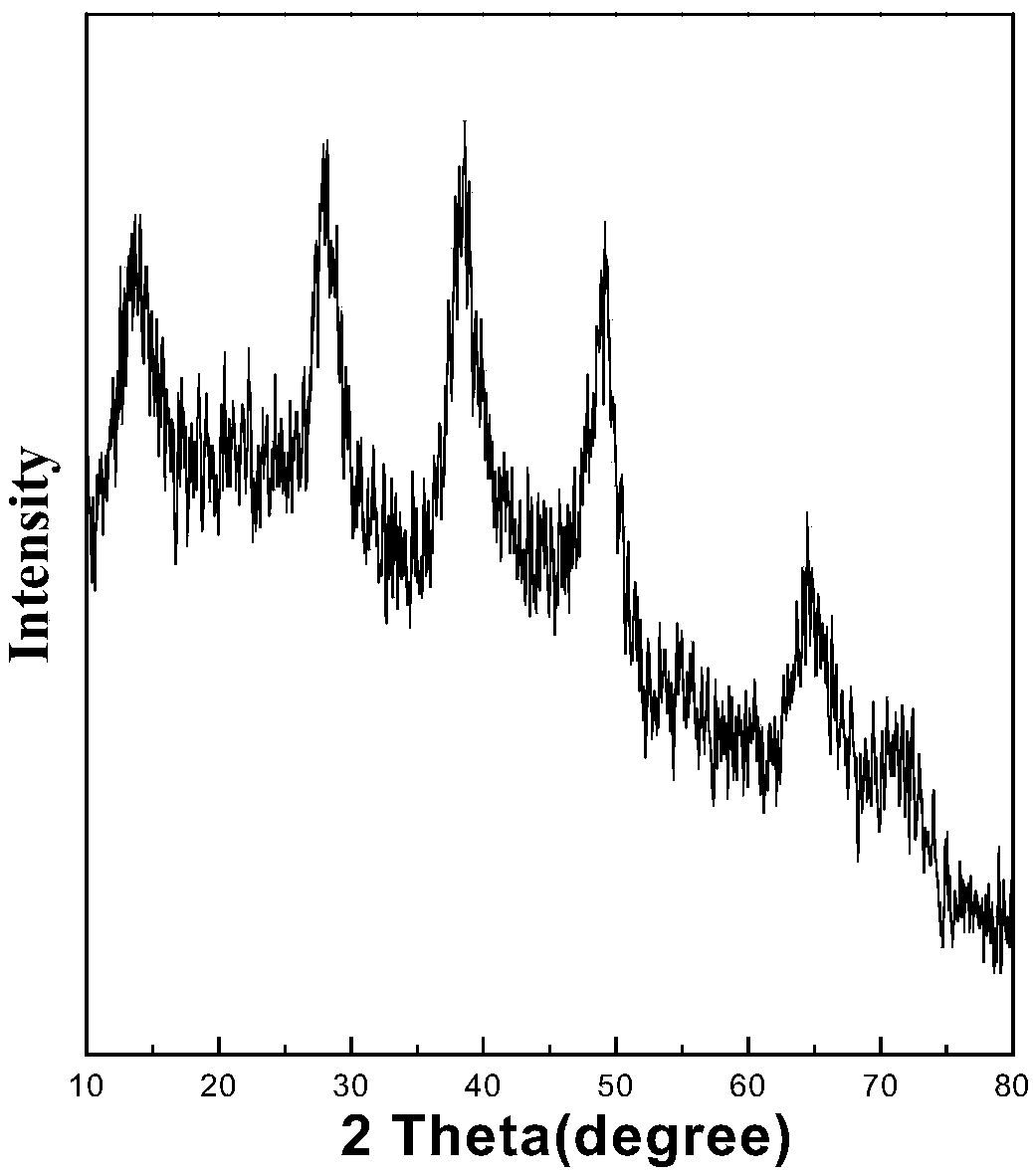

Image

Examples

Embodiment 1

[0042] A method for recycling aluminum in aluminum alloy milling waste liquid, specifically comprising the following steps:

[0043] Step 1: Centrifuge the alkaline chemical milling waste liquid to remove the precipitate in the waste liquid;

[0044] Step 2: At normal temperature and pressure, add hydrogen peroxide with a volume fraction of 30% to the waste liquid from which precipitation has been removed, and stir at a reaction temperature of 20° C. at a speed of 300 r / min for 5 minutes to fully react to obtain Reaction mixture; wherein, aluminum alloy milling waste liquid, the concentration of the component that contains is: NaOH: 100g / L; NaAlO 2 : 70g / L; Na 2 S: 20g / L; Triethanolamine: 25g / L; The number of moles of hydrogen peroxide: NaAlO in waste liquid 2 The number of moles = 15:1;

[0045] Step 3:

[0046] (1) The reaction mixture is separated from solid and liquid by vacuum filtration to obtain AlOOH crystal filter cake and filtrate;

[0047] (2) After the AlOOH c...

Embodiment 2

[0050] A method for recycling aluminum in aluminum alloy milling waste liquid, specifically comprising the following steps:

[0051] Step 1: Centrifuge the alkaline chemical milling waste liquid to remove the precipitate in the waste liquid;

[0052] Step 2: At normal temperature and pressure, add hydrogen peroxide with a volume fraction of 30% to the waste liquid from which precipitation has been removed, and stir at a reaction temperature of 20° C. at a speed of 300 r / min for 5 minutes to fully react to obtain Reaction mixture; wherein, aluminum alloy milling waste liquid, the concentration of the component that contains is: NaOH: 100g / L; NaAlO 2 : 70g / L; Na 2 S: 20g / L; Triethanolamine: 25g / L; The number of moles of hydrogen peroxide: NaAlO in waste liquid 2 The number of moles = 20:1;

[0053] Step 3:

[0054] (1) The reaction mixture is separated from solid and liquid by vacuum filtration to obtain AlOOH crystal filter cake and filtrate;

[0055] (2) After the AlOOH c...

Embodiment 3

[0058] A method for recycling aluminum in aluminum alloy milling waste liquid, specifically comprising the following steps:

[0059] Step 1: Centrifuge the alkaline chemical milling waste liquid to remove the precipitate in the waste liquid;

[0060] Step 2: At normal temperature and pressure, add hydrogen peroxide with a volume fraction of 30% to the waste liquid from which precipitation has been removed, and stir at a reaction temperature of 20° C. at a speed of 300 r / min for 5 minutes to fully react to obtain Reaction mixture; wherein, aluminum alloy milling waste liquid, the concentration of the component that contains is: NaOH: 100g / L; NaAlO 2 : 70g / L; Na 2 S: 20g / L; Triethanolamine: 25g / L; The number of moles of hydrogen peroxide: NaAlO in waste liquid 2 The number of moles = 25:1;

[0061] Step 3:

[0062] (1) The reaction mixture is separated from solid and liquid by vacuum filtration to obtain AlOOH crystal filter cake and filtrate;

[0063] (2) After the AlOOH c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com