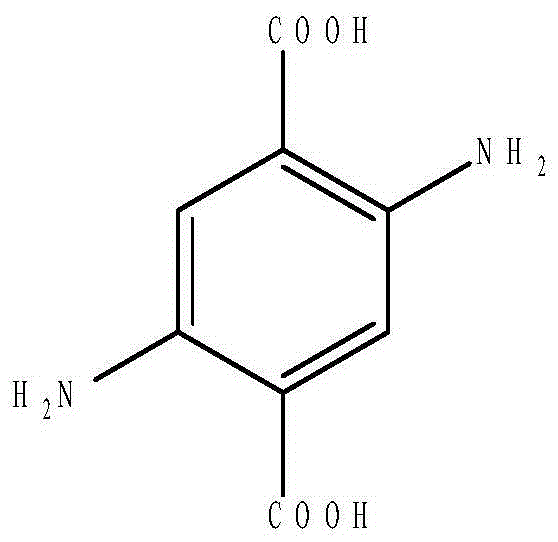

Preparation method of 2,5-diamino terephthalic acid

A technology of diaminoterephthalic acid and nitroterephthalic acid, which is applied in the preparation of 2,5-diaminoterephthalic acid and the field of 2,5-diaminoterephthalic acid, can solve complex processes, Problems such as low yield and complicated processing can achieve the effects of high purity, high yield and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

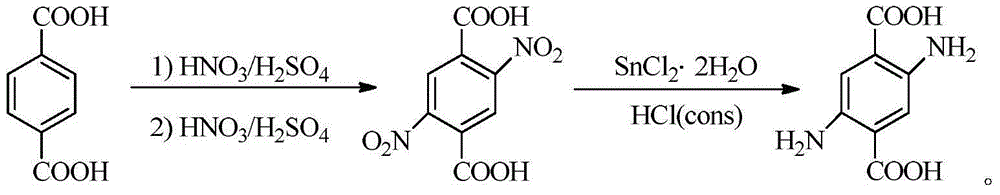

[0020] (1) Preparation of 2,5-dinitroterephthalic acid

[0021] Add 20.5g of terephthalic acid into a 500mL three-necked flask equipped with a stirrer, condenser and thermometer, add dropwise 55.2g of 98% sulfuric acid, and 121.8g of 68% nitric acid. After the dropwise addition, control the temperature at 100°C and react for 4 hours. Subsequently, 55.2 g of 98% sulfuric acid and 156.4 g of 68% nitric acid were added dropwise. After the dropwise addition, the temperature was controlled at 80° C., and the reaction was carried out for 12 hours. After the reaction, cool down, put the reaction mixture into ice water, filter the precipitate, recrystallize the filtrate in hot water, filter, and dry to obtain 26.9 g of white solid 2,5-dinitroterephthalic acid, yield 85.1% .

[0022] (2) Preparation of 2,5-diaminoterephthalic acid

[0023] Add 350mL of concentrated hydrochloric acid into a 500mL three-neck flask equipped with a stirrer, condenser and thermometer, start stirring and s...

Embodiment 2

[0025] (1) Preparation of 2,5-dinitroterephthalic acid

[0026] Add 20.5g of terephthalic acid into a 500mL three-necked flask equipped with a stirrer, condenser and thermometer, add dropwise 46.1g of 98% sulfuric acid, and 105.7g of 68% nitric acid. After the dropwise addition, control the temperature at 100°C and react for 3h. Then, 46.1 g of 98% sulfuric acid and 141.0 g of 68% nitric acid were added dropwise. After the dropwise addition, the temperature was controlled at 80° C., and the reaction was carried out for 12 hours. After the reaction, cool down, put the reaction mixture into ice water, filter the precipitate, recrystallize the filtrate in hot water, filter, and dry to obtain 27.6 g of white solid 2,5-dinitroterephthalic acid with a yield of 87.3% .

[0027] (2) Preparation of 2,5-diaminoterephthalic acid

[0028] Add 250mL of concentrated hydrochloric acid into a 500mL three-neck flask equipped with a stirrer, condenser and thermometer, start stirring and slowl...

Embodiment 3

[0030] (1) Preparation of 2,5-dinitroterephthalic acid

[0031] Add 20.5g of terephthalic acid into a 500mL three-necked flask equipped with a stirrer, condenser and thermometer, add dropwise 46.1g of 98% sulfuric acid, and 105.7g of 68% nitric acid. After the dropwise addition, control the temperature at 90°C and react for 3h. Subsequently, 46.1 g of 98% sulfuric acid and 141.0 g of 68% nitric acid were added dropwise. After the dropwise addition, the temperature was controlled at 70° C., and the reaction was carried out for 12 hours. After the reaction, cool down, put the reaction mixture into ice water, filter the precipitate, recrystallize the filtrate in hot water, filter, and dry to obtain 25.4 g of white 2,5-dinitroterephthalic acid with a yield of 80.4%.

[0032] (2) Preparation of 2,5-diaminoterephthalic acid

[0033] Add 250mL of concentrated hydrochloric acid into a 500mL three-neck flask equipped with a stirrer, condenser and thermometer, start stirring and slowly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com