Preparation method of modified lithium ion battery graphite cathode material

A lithium-ion battery, graphite negative electrode technology, applied in the direction of battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems that are difficult to achieve uniform and controllable coating amount and industrialization, the decline of composite material capacity and rate performance, and the specific surface area of materials Increase and other problems, to achieve the effect of preventing uneven coating, good controllability, and uniform viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

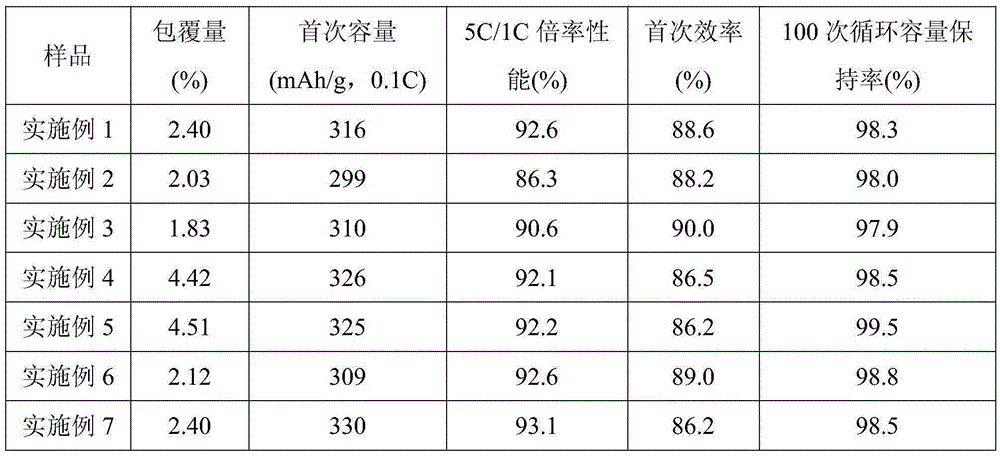

Examples

Embodiment 1

[0019] (1) Evenly mix 1kg of natural graphite with an average particle size of 16μm and 0.1kg of coal-based pitch powder, 2 / Under stirring state, the temperature was raised to 550°C at 5°C / min, and the temperature was kept constant for 2h. Take out after natural cooling, in N 2 Under protection, the temperature was raised to 1100°C at 5°C / min and kept at a constant temperature for 1h, and after natural cooling, modified graphite A was obtained by classification.

[0020] (2) Add 1.040 kg of the obtained A powder into 5 L of water-soluble thermosetting phenolic resin solution with a concentration of 0.1 kg / L, and stir at 90° C. for 1 h to obtain solution B.

[0021] (3) Solution B was filtered and dried, rapidly heated to 150°C and kept at a constant temperature for 5 minutes, and cooled to room temperature to obtain precursor powder, which weighed 1.065kg, and the coating amount of water-soluble thermosetting phenolic resin was calculated to be 2.40%.

[0022] (4) Raise the...

Embodiment 2

[0024] (1) Evenly mix 1kg of natural graphite with an average particle size of 30μm and 0.1kg of coal-based pitch powder, 2 / Under stirring state, the temperature was raised to 550°C at 5°C / min, and the temperature was kept constant for 2h. Take out after natural cooling, in N 2 Under protection, the temperature was raised to 1100°C at 5°C / min and kept at a constant temperature for 1h, and after natural cooling, modified graphite A was obtained by classification.

[0025] (2) Add 1.036 kg of the obtained A powder into 5 L of water-soluble thermosetting phenolic resin solution with a concentration of 0.1 kg / L, and stir at 90° C. for 1 h to obtain solution B.

[0026] (3) Solution B was filtered and dried, rapidly heated to 150°C and kept at a constant temperature for 5 minutes, and cooled to room temperature to obtain precursor powder, which weighed 1.057kg, and the coating amount of water-soluble thermosetting phenolic resin was calculated to be 2.03%.

[0027] (4) Raise the...

Embodiment 3

[0029] (1) Evenly mix 10kg of natural graphite with an average particle size of 16μm and 1.0kg of coal-based pitch powder, 2 / Under stirring state, the temperature was raised to 550°C at 5°C / min, and the temperature was kept constant for 2h. Take out after natural cooling, in N 2 Under protection, the temperature was raised to 1100°C at 5°C / min and kept at a constant temperature for 1h, and after natural cooling, modified graphite A was obtained by classification.

[0030] (2) Add 10.37 kg of the obtained A powder into 50 L of water-soluble thermosetting phenolic resin solution with a concentration of 0.1 kg / L, and stir at 90° C. for 1 h to obtain solution B.

[0031] (3) Solution B was filtered and dried, rapidly heated to 150°C and kept at a constant temperature for 10 minutes, and cooled to room temperature to obtain precursor powder, which weighed 10.56kg, and the coating amount of water-soluble thermosetting phenolic resin was calculated to be 1.83%.

[0032] (4) Raise ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com