Electrochromism assembly provided with composite electrochromism materials

An electrochromic material and electrochromic technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as affecting the scope of application, not disclosing in detail the composition and process of electrochromic layer materials, and unable to have coloring memory. , to achieve the effect of accelerating transmission speed and rapid color change response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

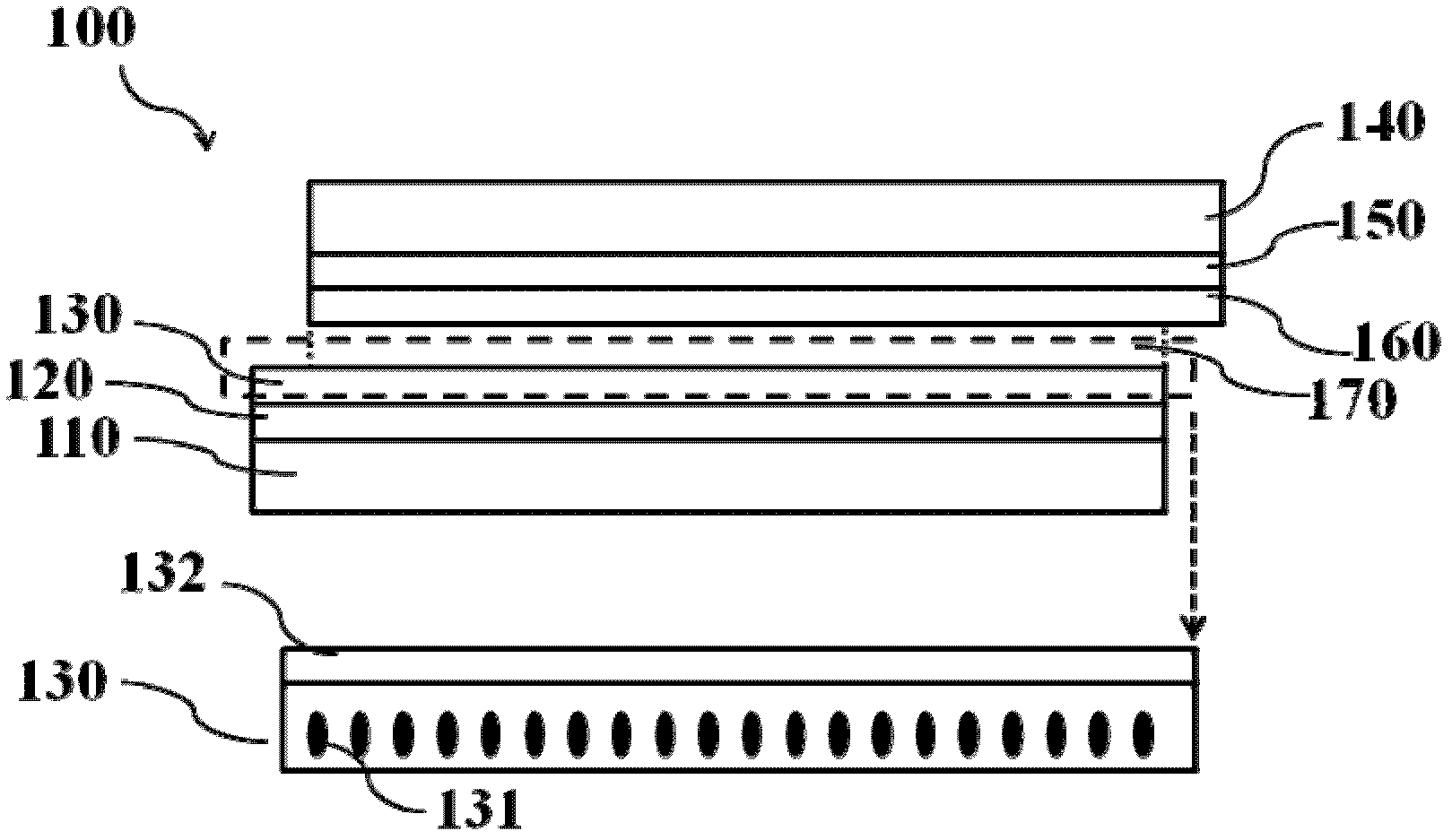

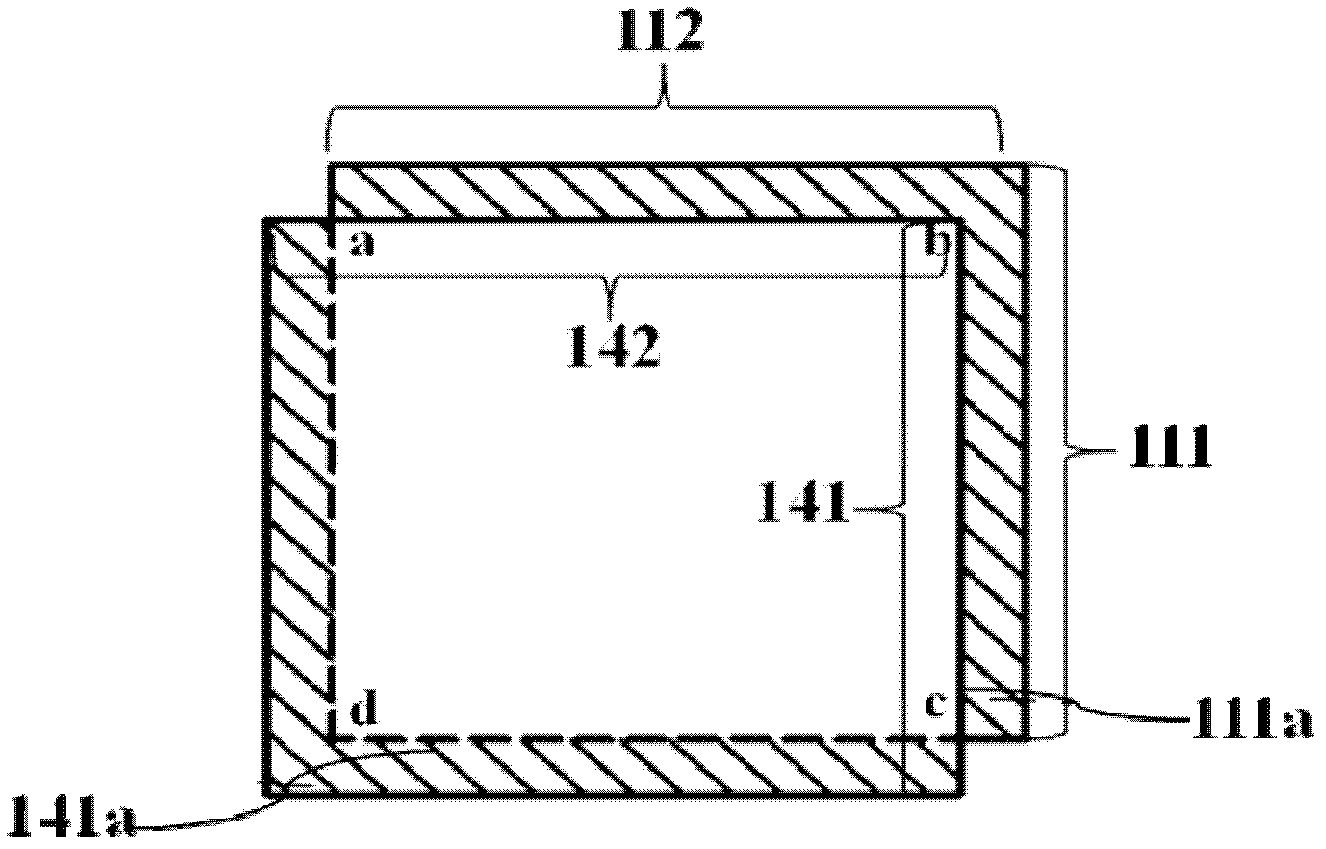

Embodiment 1

[0052]Firstly, the glass (1.4m x 1.1m) is first treated with a degreasing agent to remove the surface oil, and then washed with water to keep the glass surface clean without leaving any degreasing agent, and then the glass surface is cleaned with hydrochloric acid , and then washed with water to remove excess hydrochloric acid solution, and finally the glass was coated with a 200nm ITO film by sputtering. Next, at O 3 / O 2 Synthesis of molar WO by sol-gel method under mixed gas environment 3 :TiO 2 =96:4 thin film, and deposited on the working electrode glass coated with indium tin oxide (indium tinoxide, ITO). On the other hand, the counter electrode also forms a NiO with a thickness of 300nm on the surface of the ITO glass in the above-mentioned manner; The relative distance between the length and the length and the width and the width of the two transparent conductive substrates is between 0.5 cm. Finally, it is sealed with a sealant containing glass bead spacers along...

Embodiment 2

[0055] Embodiment 2 is as big as the step of embodiment 1, and its main difference is: the WO formed on the ITO glass surface 3 The thickness of the working electrode and the NiO of the counter electrode are changed to 400 nanometers; the metal doping material is changed to Pt, and Pt:WO 3 The molar ratio is 5:95; and the solid electrolyte is changed to a colloidal electrolyte. Colloidal electrolyte is an electrolyte mixed with ionic liquid and colloidal polymer. Wherein the ionic liquid is 1M LiClO of lithium salt 4 , and mixed with [EMIM][BF 4 ] ionic liquid (wherein EMIM is ethylmethyl imidazolium ion [ethylmethyl imidazolium]); and the colloidal polymer is ethylene-vinyl acetate copolymer (Ethylenevinyl accetate copolymer, EVA). Among them, the ionic conductivity of the formed colloidal polymer electrolyte is about 10 at room temperature -3 S / cm. The finished electrochromic device develops a dark blue color with a transmittance of about 20%; when quenched, the electro...

Embodiment 3

[0057] Embodiment 3 is as large as the steps of embodiment 2, and its main difference is: the metal doping material is changed to Pt: WO 3 The molar ratio is 3:97. The prepared electrochromic device develops a dark blue color with a transmittance of about 24%; when quenched, the electrochromic device is transparent with a transmittance of 70%. As described in Example 1, the electrochromic device provides an excellent memory effect over 75 hours. It is worth noting that the driving voltage of the electrochromic device is 2.7 volts, which can produce the electrochromic effect, and the dimming time can be less than 1 second.

[0058] In summary, an electrochromic component with a composite electrochromic material of the present invention has the following effects:

[0059] The electrochromic layer of the electrochromic component of the present invention is doped with a metal doping material, which accelerates the transmission speed of electrons, resulting in a rapid electrochro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com