Preparation method of sodium-sulfur battery positive electrode material and application thereof

A sodium-sulfur battery and positive electrode material technology, applied in the field of material chemistry, can solve the problems of affecting the sulfur loading of active materials and losing the layered structure, and achieve the effects of high industrialization feasibility, increased energy density, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

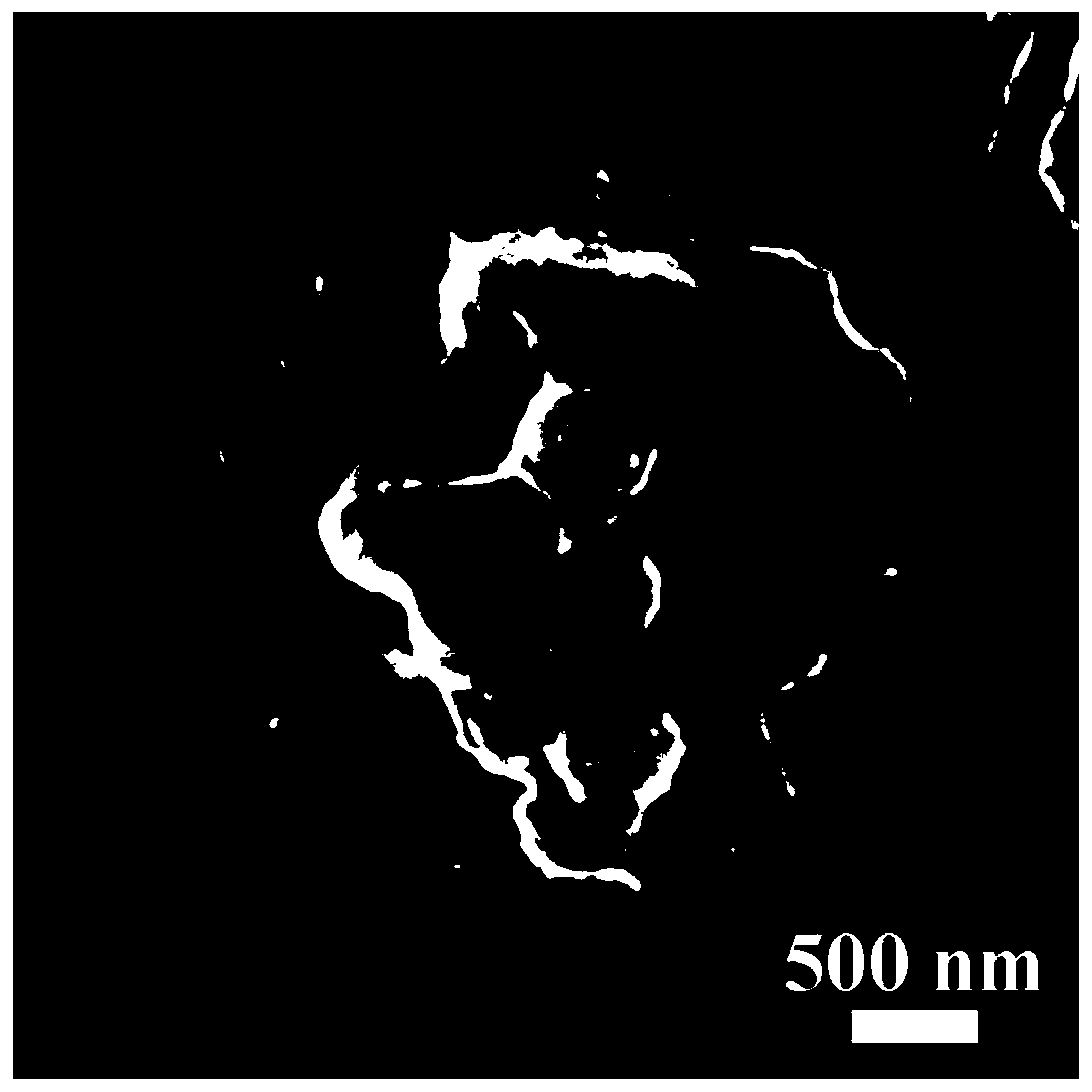

[0028] Ti with spherical three-dimensional porous structure 3 C 2 / S composite cathode material, comprising the following steps:

[0029] The first step is to prepare Ti 3 C 2 Dispersions.

[0030] Phase MAX to Ti 3 C 2 Al powder is slowly dispersed in deionized water, and the MAX phase Ti is made by a high-power ultrasonic machine 3 C 2 The Al powder is uniformly dispersed in deionized water to obtain an aqueous dispersion. where the MAX phase Ti 3 C 2 The mass volume ratio of Al powder to deionized water is 1:200g / mL. Then, under the action of magnetic stirring, the HF solution was slowly added dropwise. Wherein, the concentration of the HF solution is 40 wt%, and the volume of the HF solution is 50% of the volume of the aqueous phase dispersion. After the dropwise addition was completed, the magnetic stirring was continued for 24 h. After the magnetic stirring is completed, wait for the reaction system to stand for stratification, and use deionized water and ab...

Embodiment 2

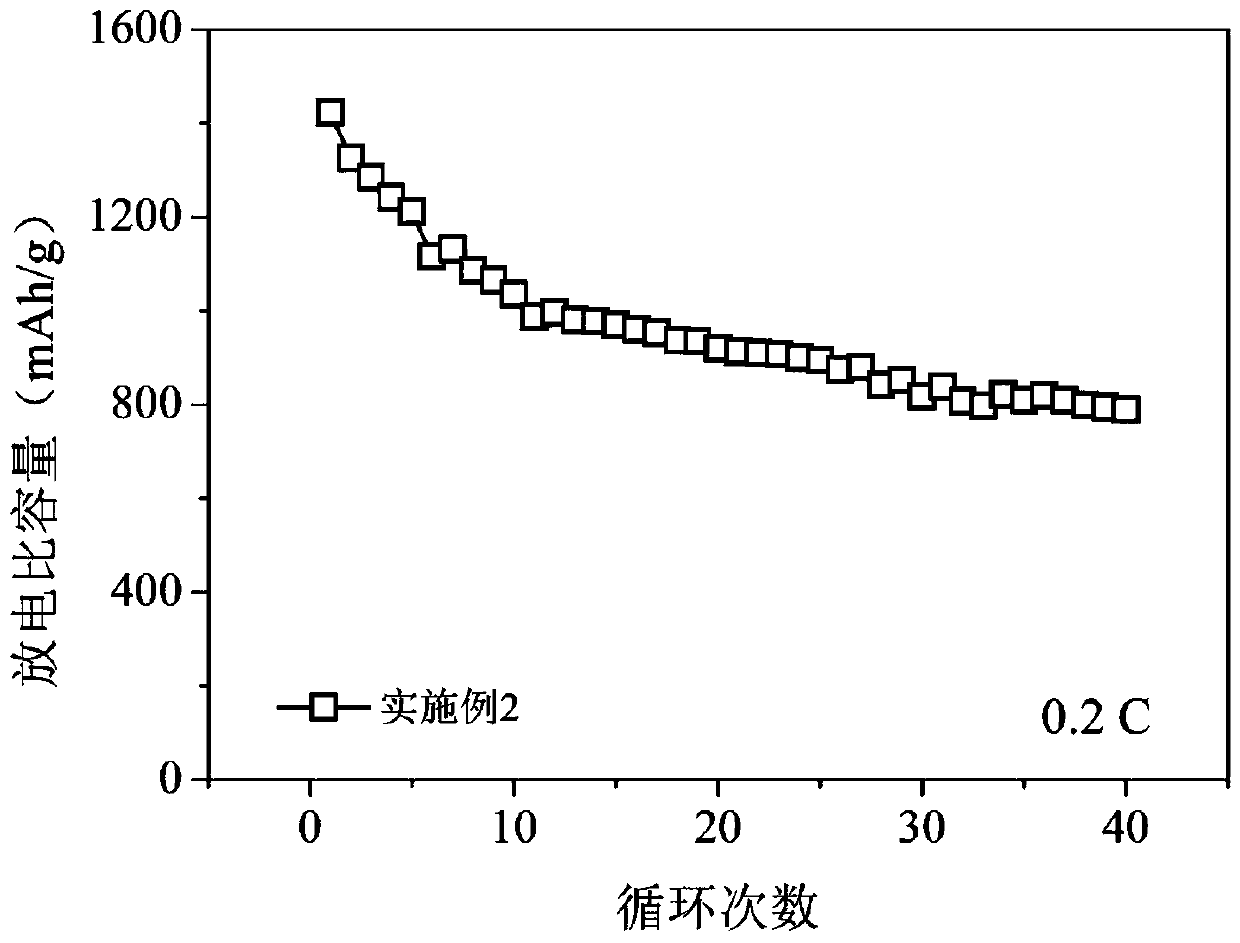

[0039] Embodiment 2: other is the same as embodiment 1, difference is the second step Ti 3 C 2 Solute and SiO 2 The mass ratio of solute is 1:40.

Embodiment 3

[0040] Embodiment 3: other is with embodiment 1, difference is the second step Ti 3 C 2 Solute and SiO 2 The mass ratio of solute is 1:50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com