Structural acoustic attenuation panel

A sound-attenuating panel and structural technology, applied in the direction of sound-generating equipment, instruments, etc., can solve the problems of cumbersome manufacturing, increase production cost and maintenance cost, etc., and achieve the effect of reducing assembly steps, increasing effective acoustic surface, and simplifying assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

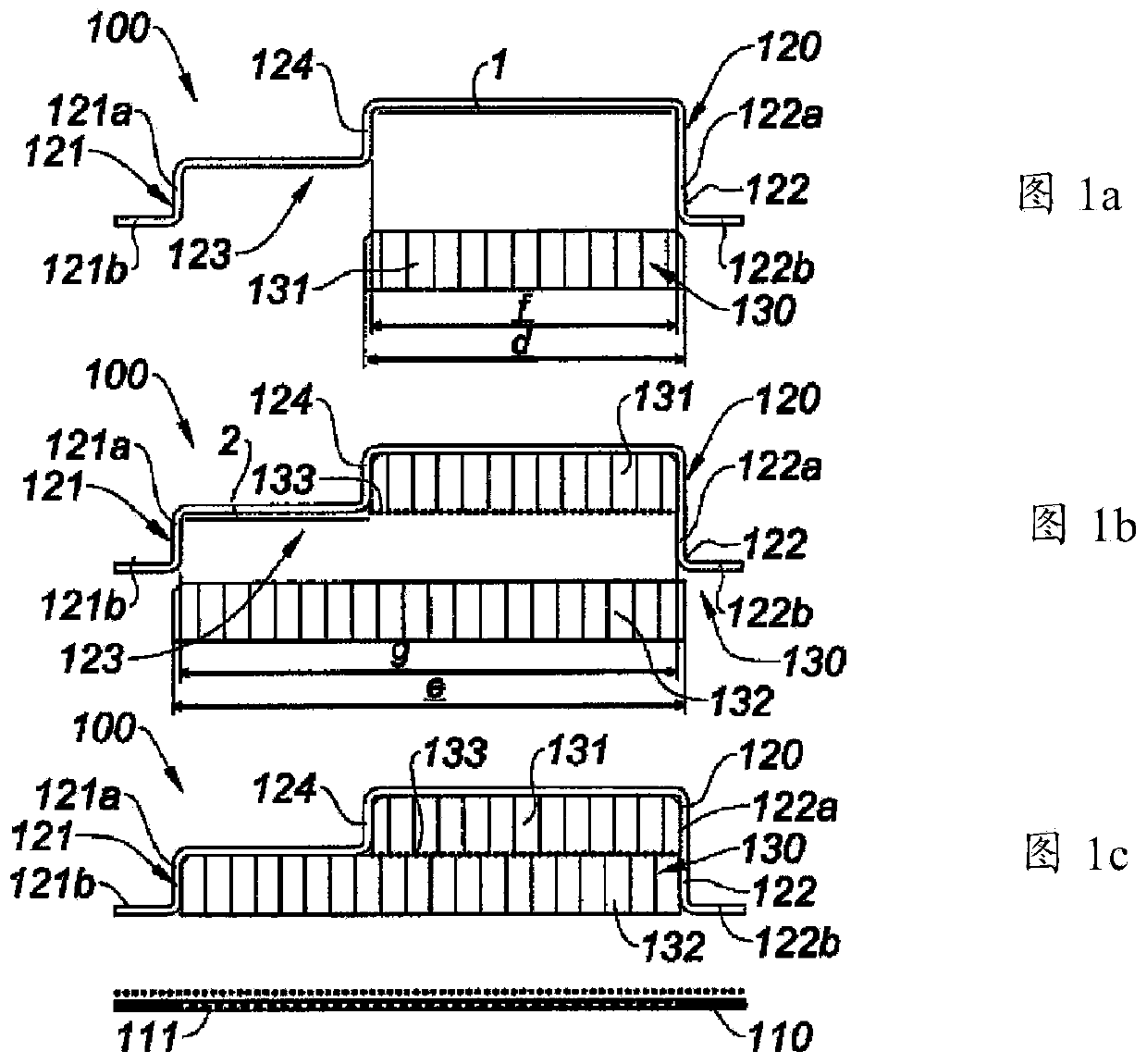

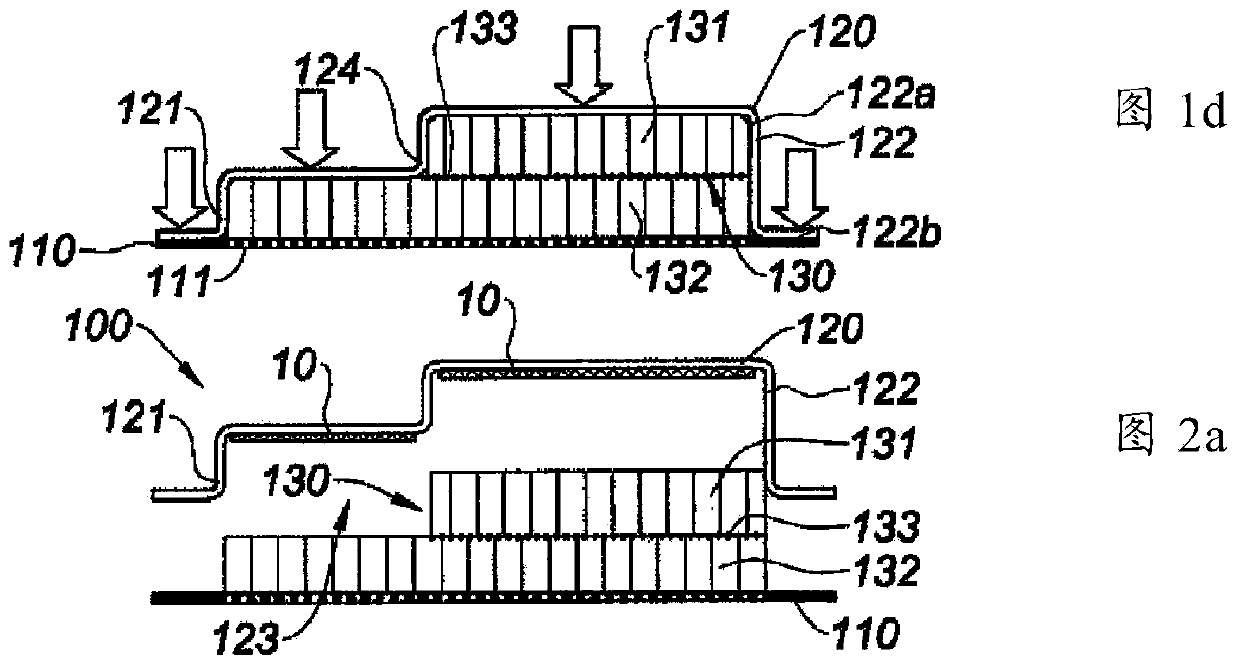

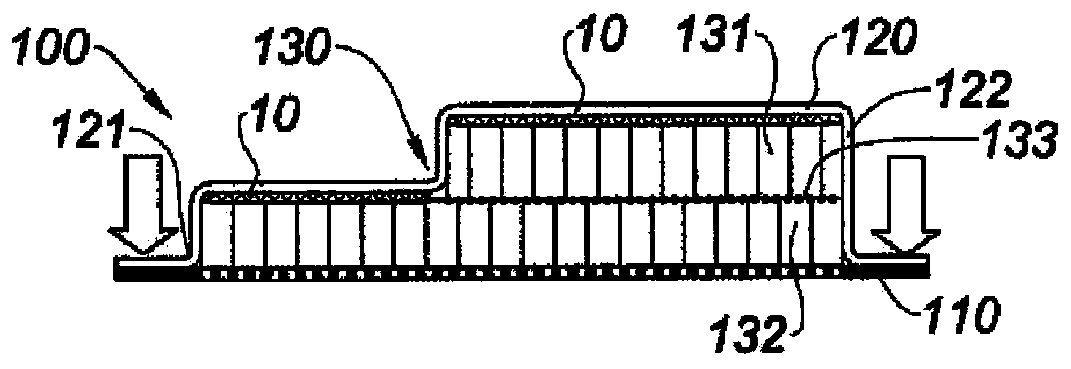

[0058] Referring to Figures 1a to 1d, the sound attenuating panel 100 comprises:

[0059] - an acoustically resistive surface 110 with acoustic holes,

[0060] - solid skin 120,

[0061] - an acoustic structure 130 comprising sound absorbing material and arranged between said acoustically resistive skin 110 and the solid skin 120 .

[0062] As shown in these figures, the acoustic structure 130 may include a honeycomb structure formed of honeycomb core units or NIDA.

[0063] In an alternative embodiment, it may include a porous material with sound absorbing properties instead of the NIDA structure.

[0064] Such porous materials have an open structure, ie, open cells capable of absorbing acoustic energy.

[0065] For example, the porous material mentioned above may be made of a foam-type material or a material in an expanded form.

[0066] Such an acoustic structure 130 may or may not be of the distributed acoustic type.

[0067] The acoustic structure 130 may comprise one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com