Isothermal quenching nodular cast iron as well as preparation method and application thereof

A ductile iron and isothermal quenching technology, which is applied in casting molding equipment, molds, mold components, etc., can solve the problems of easy deformation performance and substandard performance, and achieve the effect of solving the overall performance substandard.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

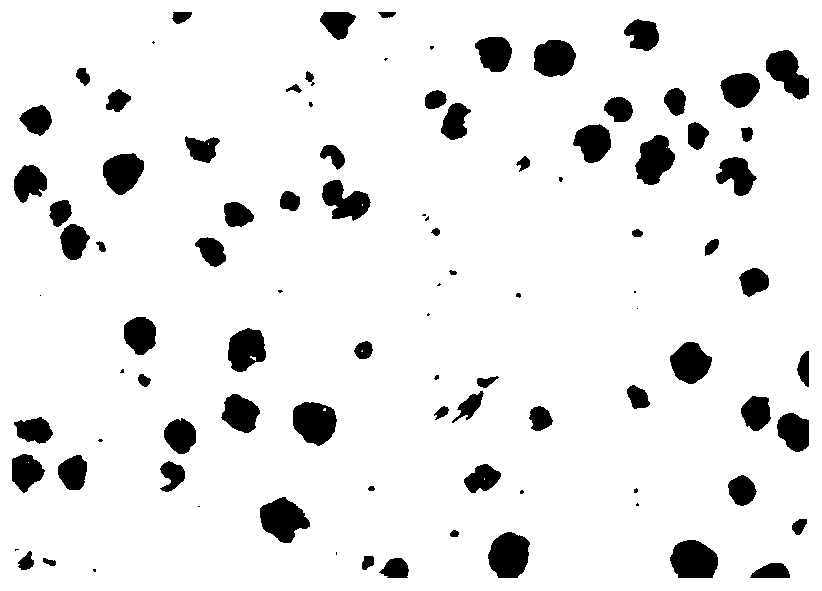

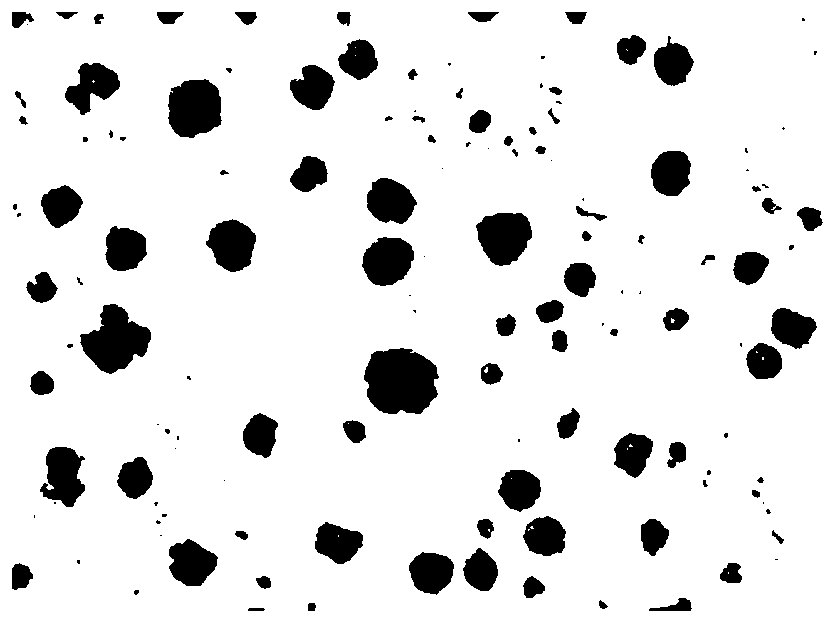

Image

Examples

Embodiment 1

[0069] A kind of austempering ductile iron, said austempering ductile iron comprises the following components in weight percentage: C3.60wt%, Si 2.31wt%, Mn 0.22wt%, P 0.017wt%, S 0.013wt%, Cu 0.70 wt%, Mo0.10wt%, Mg 0.035wt%, the balance is iron.

[0070] The preparation method of the austempering ductile iron comprises the following steps:

[0071] (1) The melted molten iron is inoculated by rushing into the spheroidization method, pouring is carried out after the inoculation is completed, and nodular cast iron is obtained after the pouring is completed and cooled; wherein, the addition of the nodularizing agent in the spheroidization inoculation is 1 / 2 of the molten iron quality 1.2%, the nodulizer is Mg 6 RE 2 Rare earth magnesium spheroidizer, particle size 10-30mm; the addition amount of ferrosilicon inoculant in the spheroidization inoculation is 0.6% of the mass of molten iron, and the ferrosilicon inoculant is FeSi 75 Al 1.5-B ferrosilicon, particle size 8-20mm; i...

Embodiment 2

[0075] A kind of austempering ductile iron, said austempering ductile iron comprises the following components in weight percentage: C3.75wt%, Si 2.47wt%, Mn 0.40wt%, P 0.025wt%, S 0.013wt%, Cu 0.80 wt%, Mo0.20wt%, Mg 0.052wt%, and the balance is iron.

[0076] The preparation method of the austempering ductile iron comprises the following steps:

[0077] (1) The melted molten iron is inoculated by rushing into the spheroidization method, pouring is carried out after the inoculation is completed, and nodular cast iron is obtained after the pouring is completed and cooled; wherein, the addition of the nodularizing agent in the spheroidization inoculation is 1 / 2 of the molten iron quality 1.4%, the nodulizer is Mg 6 RE 2 Rare earth magnesium spheroidizer, particle size 10-30mm; the addition amount of ferrosilicon inoculant in the spheroidization inoculation is 0.80% of the mass of molten iron, and the ferrosilicon inoculant is FeSi 75 al 1.5 -B ferrosilicon, particle size 8-2...

Embodiment 3

[0081] A kind of austempering nodular cast iron, the austempering nodular cast iron includes the following components in weight percentage: C3.67wt%, Si 2.41wt%, Mn 0.32wt%, P 0.019wt%, S 0.012wt%, Cu 0.75 wt%, Mo0.15wt%, Mg 0.043wt%, and the balance is iron.

[0082] The preparation method of the austempering ductile iron comprises the following steps:

[0083] (1) The melted molten iron is inoculated by rushing into the spheroidization method, pouring is carried out after the inoculation is completed, and nodular cast iron is obtained after the pouring is completed and cooled; wherein, the addition of the nodularizing agent in the spheroidization inoculation is 1 / 2 of the molten iron quality 1.30%, the nodulizer is Mg 6 RE 2 Rare earth magnesium spheroidizer, particle size 10-30mm; the addition amount of ferrosilicon inoculant in the spheroidization inoculation is 0.70% of the mass of molten iron, and the ferrosilicon inoculant is FeSi 75 al 1.5 -B ferrosilicon, particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com