Carbide-carrying austempered ductile iron and quenching technology thereof

A technology of austempering ductile iron and austempering, which is applied in the field of heat treatment of metal materials, can solve the problems of high production cost, low toughness, and low productivity, and achieve the effects of good processing performance, good mechanical properties, and low safety cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] A kind of austempering ductile iron with carbides in this embodiment includes the following components in weight percentage,

[0086] C 3.3 ~ 3.8%

[0087] P 0.01~0.05%

[0088] S 0.005~0.02%

[0089] Mg 0.025 ~ 0.045%

[0090] Re 0.015 ~ 0.03%

[0091] Sn 0.1~0.8%

[0092] Si 2.8~~3.6%

[0093] Mn 1.5~2.8%

[0094] Cr 0.2~0.8%

[0095] B 0.02~0.08%

[0096] The rest is Fe.

[0097] The present invention adjusts the chemical element composition of the austempering ductile iron with carbides to make it In Mn, Si alloy Basically, it contains 0.1~0.8% of Sn, 2.8~3.5% of Si, and 0.2~0.8% of Cr. Due to the addition of appropriate amount of Cr and B, it can properly adjust the carbide content during heat treatment and improve wear resistance and hardenability. At the same time, compared with the existing technology, a small amount of Sn and Si content is added, so that Sn and Si jointly increase the potential of the substrate electrode, and together with Cr form a ...

Embodiment 2

[0115] A kind of austempering nodular iron with carbides of the present invention comprises the following components by weight percentage,

[0116] C 3.5~3.7%

[0117] P 0.02~0.03%

[0118] S 0.005~0.01%

[0119] Mg 0.03~0.04%

[0120] Re 0.02~0.025%

[0121] Sn 0.3~0.5%

[0122] Si 3.0~3.2%

[0123] Mn 1.9~2.1%

[0124] Cr 0.4~0.6%

[0125] B 0.02~0.07%

[0126] RE-B 0.1~0.3%

[0127] The rest is Fe.

[0128] The above-mentioned RE-B is a rare earth-boron composite modifier, and its components are common knowledge in the field, and will not be described in detail here. The austempering ductile iron with carbides of the present invention adds a rare earth-boron composite modifier (RE-B) to inoculate and modify the carbides in the workpiece, which can effectively reduce the brittleness of the product and ensure its sufficient strength and proper toughness , to further increase the wear resistance.

[0129] The matrix structure of the austempering ductile iron with car...

Embodiment 3

[0143] A kind of austempering nodular iron with carbides of the present invention comprises the following components by weight percentage,

[0144] C 3.6%

[0145] P 0.0253%

[0146] S 0.008%

[0147] Mg 0.035%

[0148] Re 0.022%

[0149] Sn 0.4%

[0150] Si 3.1%

[0151] Mn 2.0%

[0152] Cr 0.5%

[0153] B 0.04%

[0154] RE-B 0.2%

[0155] The rest is Fe.

[0156] The main technical solutions of this embodiment are basically the same as those of Embodiment 1 or Embodiment 2, and the features not explained in this embodiment are explained in Embodiment 1 or Embodiment 2, and will not be repeated here.

[0157] The matrix structure of the austempering ductile iron with carbides is composed of the following components by weight percentage:

[0158] Lower bainite 50~68%

[0159] Tempered martensite 20~30%

[0160] Eutectic carbide 10~28%

[0161] Carbon-rich austenite 2~9%.

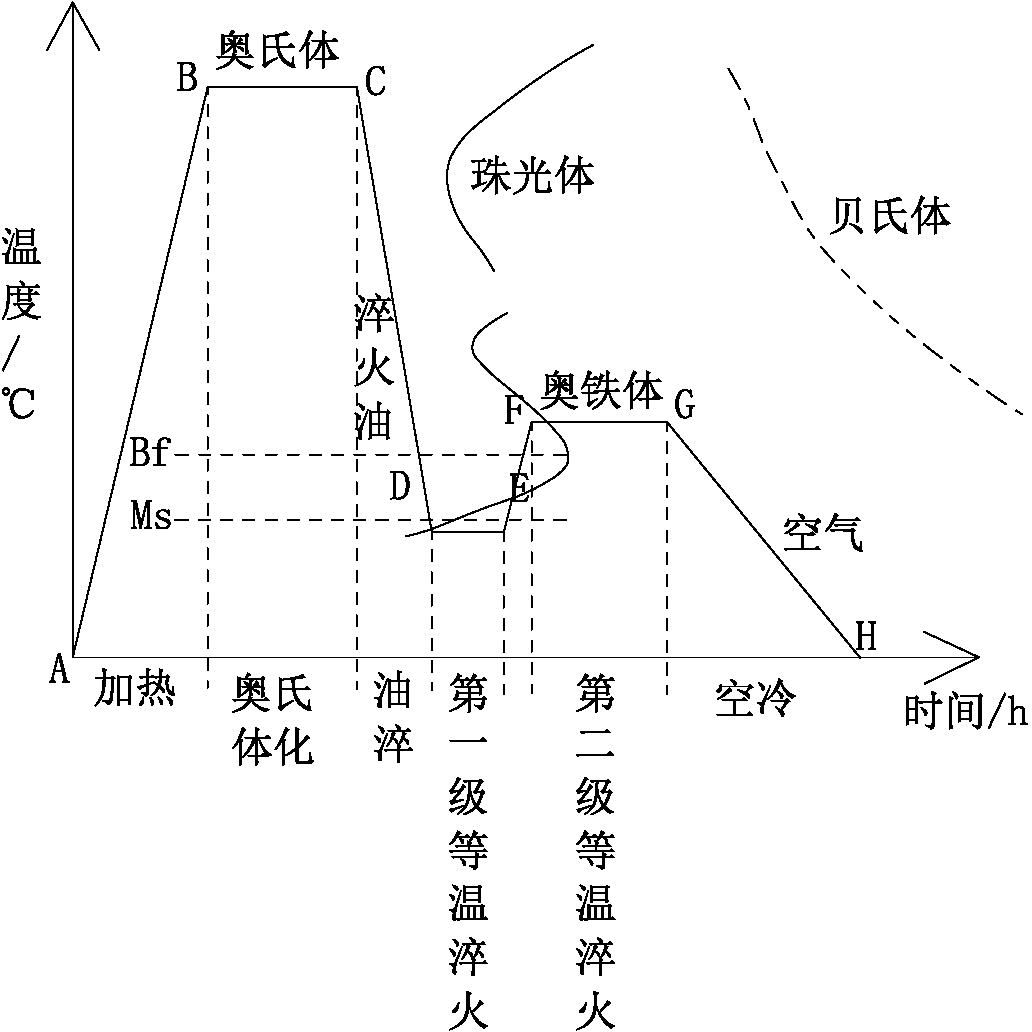

[0162] Simultaneously, a kind of band carbide austempering ductile iron quenching process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com