Process for manufacturing bimetal compound casting liner plate

A technology of compound casting and production process, which is applied in the field of bimetallic composite liners, can solve problems such as difficult to meet, and achieve the effects of low production cost, high service life and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

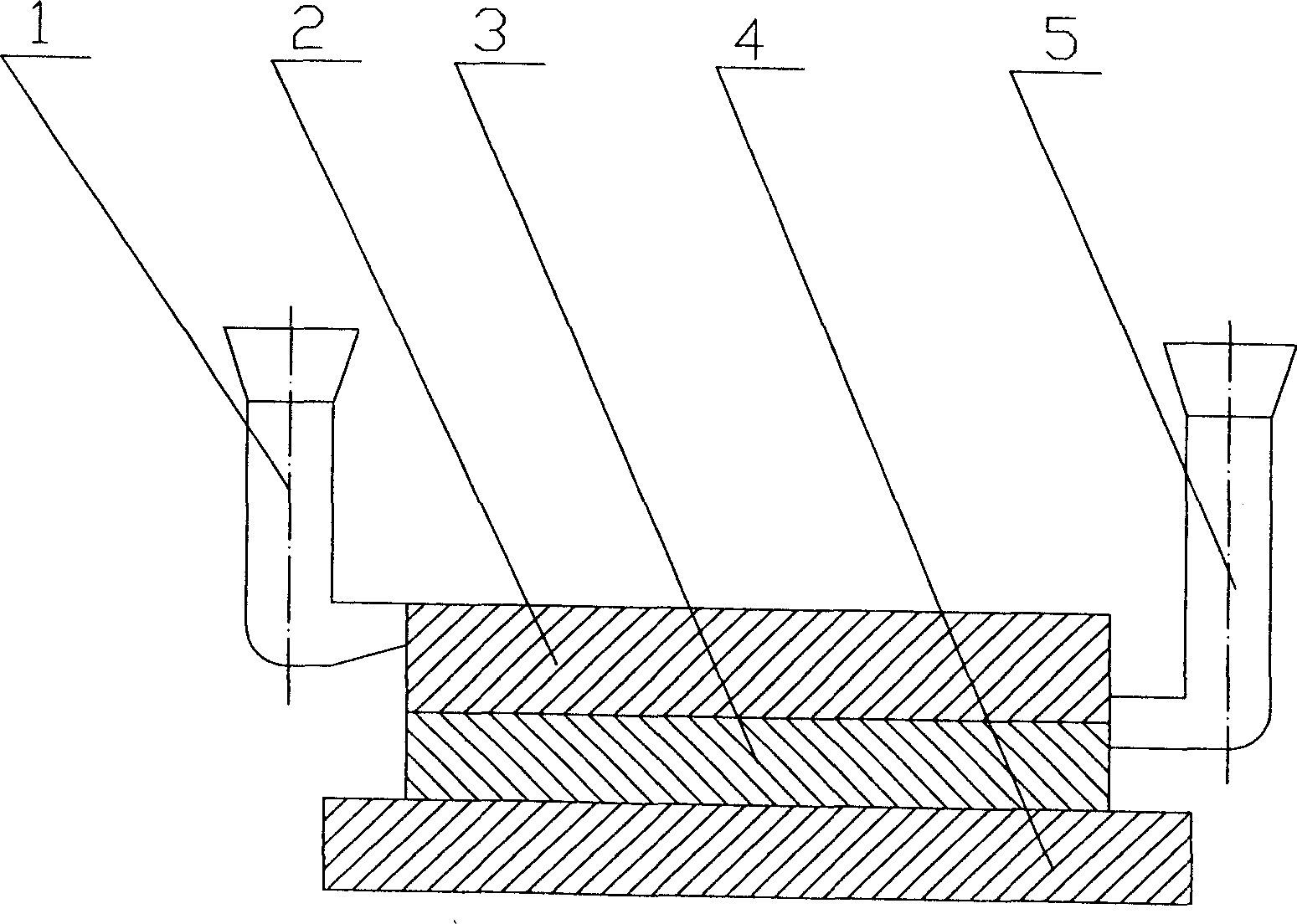

[0009] When pouring, put the working layer upwards, set the chilling material (4) under the cavity, and pour a certain amount of liquid metal of medium-carbon low-alloy bainite wear-resistant steel from the gate (5) at a relatively fast speed, so that It becomes the tougher liner (3). After an interval of 2 to 60 seconds, the liquid metal of high-carbon and low-alloy bainite wear-resistant steel is poured from the pouring riser (1) to make it a wear-resistant layer (2) with high wear resistance. The diameter of the pouring riser (1) should be larger, so that it has a better feeding effect. Heat the cleaned liner to 860~920C 0 , keep warm for 40-100 minutes, then put it into 280-350C 0 The nitrate solution isothermally quenched, and the liner can be taken out after 60 to 120 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com