Nano bainite hot work die steel and preparation method thereof

A technology for hot work die steel and nano-bainite, which is applied in the field of die steel and achieves the effects of being beneficial to industrialized production, the preparation process is simple and feasible, and the preparation efficiency is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention also provides a preparation method of nano-bainite hot work die steel, which includes the following steps.

[0034] (1) Smelting: Feed materials according to the design requirements of the composition of the steel. The steel includes: C 0.32~0.45, Si 1.20~1.50, Mn 0.20~0.50, Cr 4.75~5.05, Mo 1.10~1.75, V 0.80~1.00, P<0.02, S<0.01, the rest are Fe and unavoidable impurities, then melted in a vacuum induction furnace and cast into ingots. Preferably, the composition of the steel includes: C 0.38, Si 1.50, Mn 0.26, Cr 5.05, Mo1.37, V 1.00, P 0.0082, S 0.0042 in terms of mass percentage, and the rest is Fe and unavoidable impurities.

[0035] (2) Annealing and hot rolling: the steel ingot is annealed, hot rolled, and air cooled to room temperature after hot rolling to obtain a hot rolled slab.

[0036] (3) Quenching and tempering pretreatment: heat the hot-rolled slab in step (2) to 1050~1150°C, keep it warm for 10~15min, cool it to room temperature with oil,...

Embodiment 1

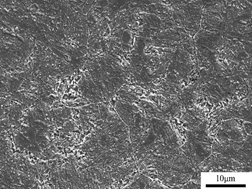

[0040] Embodiment 1, see attached figure 1 , in this example:

[0041] A. According to the mass percentage of C 0.38, Si 1.5, Mn 0.26, Cr 5.05, Mo 1.37, V 1.00, P 0.0082, S0.0042, the ratio of Fe balance, calculate the feeding ratio, and smelt in a vacuum high-frequency induction furnace+ After electroslag remelting, it is poured into a round ingot with a diameter of Φ80mm.

[0042] B. Annealing and hot rolling: heat the steel ingot to 1150°C for 5 hours for uniform annealing, and cool with the furnace. Afterwards, the round ingot is hot-rolled at 1150°C to form a steel plate with a thickness of 25mm; finally, the hot-rolled blanked steel plate is annealed after forging.

[0043] C. Quenching and tempering pretreatment: reheat the hot-rolled slab to 1050° C. in the furnace, keep it warm for 10 minutes, and put it into oil to quench and cool to room temperature after being released from the furnace to obtain a quenched slab. Reheat the quenched slab to 720°C for 1 hour, and ai...

Embodiment 2

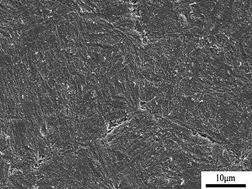

[0045] Embodiment 2, see attached figure 2 , in this example:

[0046] A. According to the mass percentage of C 0.38, Si 1.5, Mn 0.26, Cr 5.05, Mo 1.37, V 1.00, P 0.0082, S0.0042, the ratio of Fe balance, calculate the feeding ratio, and smelt in a vacuum high-frequency induction furnace+ After electroslag remelting, it is poured into a round ingot with a diameter of Φ80mm.

[0047] B. Annealing and hot rolling: heat the steel ingot to 1150°C for 5 hours for uniform annealing, and cool with the furnace. Afterwards, the round ingot is hot-rolled at 1150°C to form a steel plate with a thickness of 25mm; finally, the hot-rolled blanked steel plate is annealed after forging.

[0048] C. Quenching and tempering pretreatment: reheat the hot-rolled slab to 1100° C. in the furnace, keep it warm for 10 minutes, put it into oil and quench it to room temperature after coming out of the furnace, and obtain a quenched slab. Reheat the quenched slab to 720°C for 1 hour, and air-cool to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com