Isothermal quenching nodular cast iron roller for push-pull vehicle on heat treatment production line and production method thereof

A technology of austempering and ductile iron, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problem of wear rate affecting equipment reliability, etc., and achieve the effect of small notch sensitivity, stable operation of parts, and good shock absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

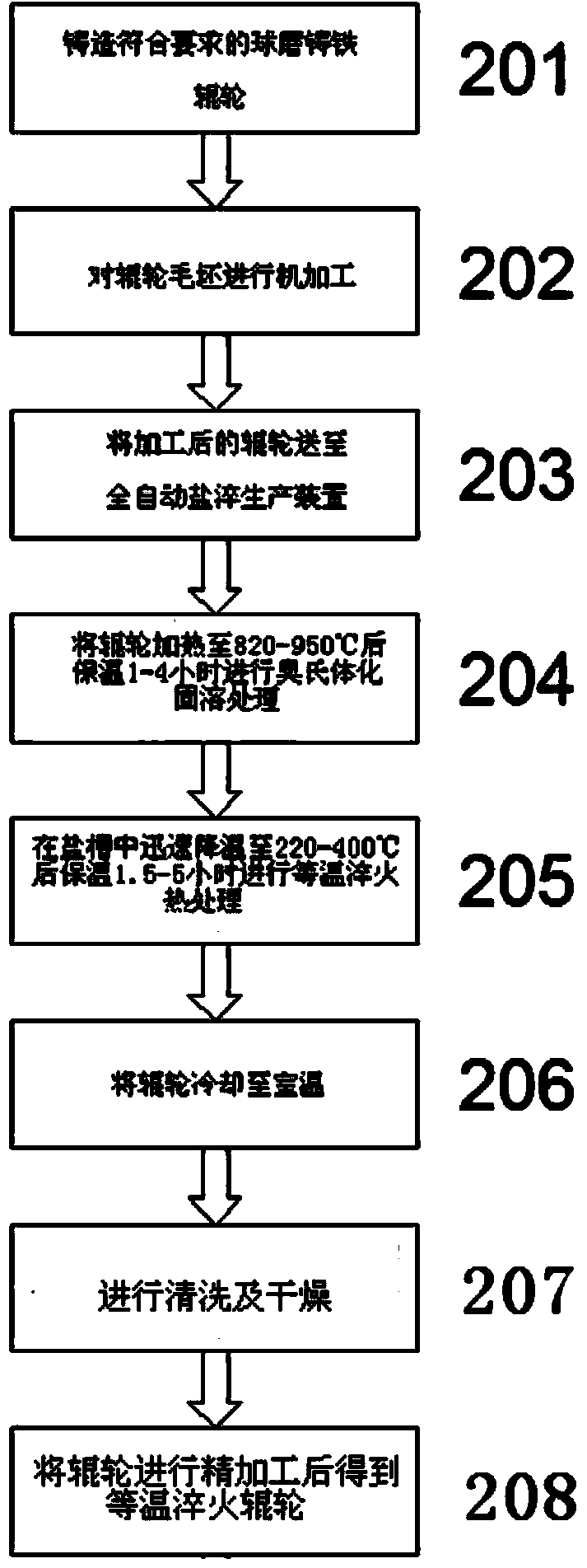

Method used

Image

Examples

Embodiment Construction

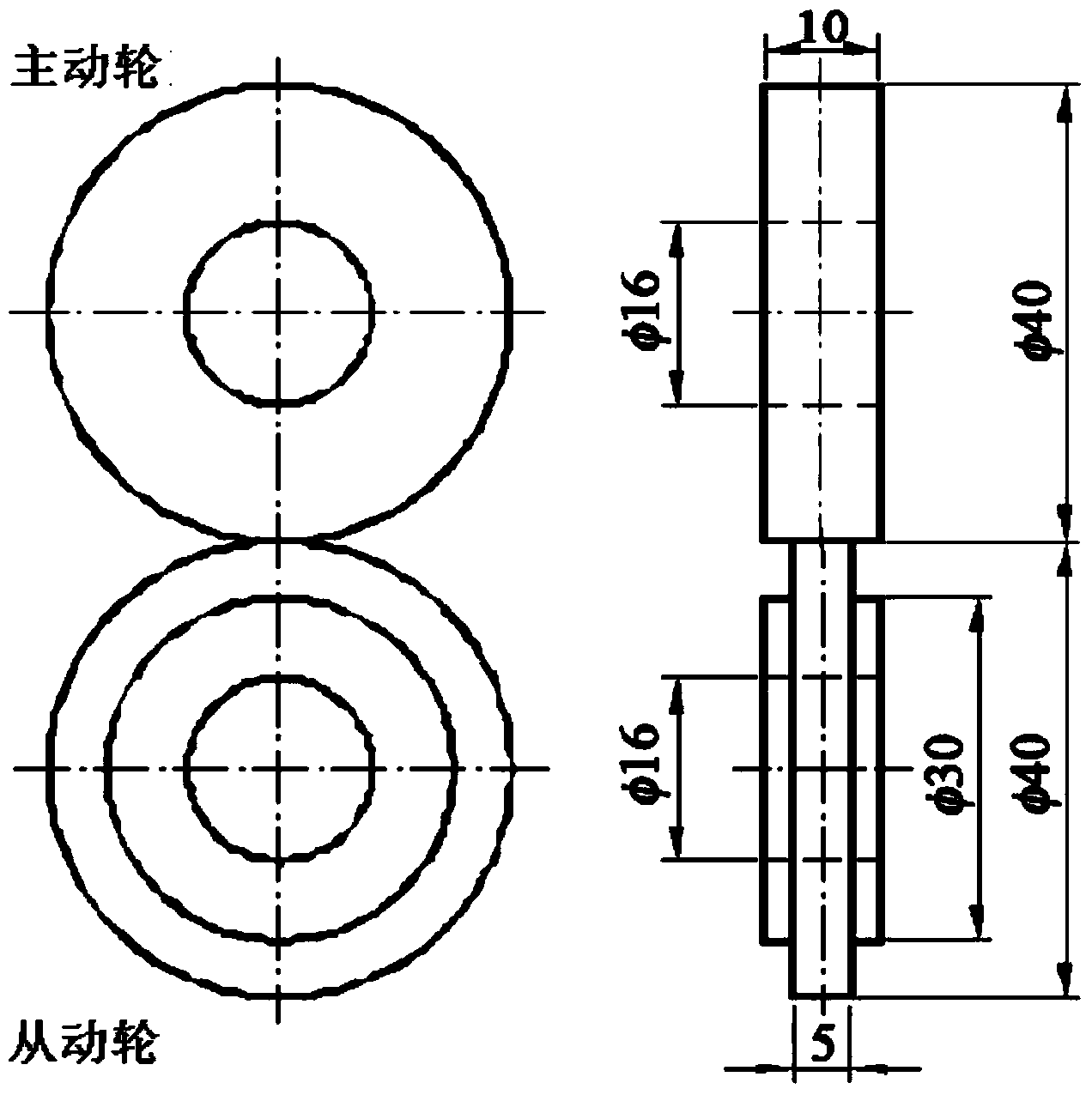

[0048] The working conditions of rollers can be divided into two categories: heavy load and light load according to the load. Under heavy load conditions, the surface pressure of the contact surface between the roller and the track is greater than 850 N / mm2. The high-carbon austenite part in the austempering ductile iron roller matrix of the present invention is transformed into high-carbon martensite, which can increase the hardness of the surface layer by about 10 degrees Rockwell hardness at most, can resist surface wear, and improve wear resistance; and The above processes continue to occur on the new sub-surface. The more it is worn, the harder it becomes. The surface layer is hardened while the core still maintains strong toughness. The outer hard and inner tough are both resistant to wear and impact. In this case, the present invention adopts a higher isothermal heat treatment quenching temperature to improve the toughness and extensibility of the roller to resist the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com