Method for producing wheel made of austempered ductile iron (ADI) material

A production method, wheel technology, applied in furnaces, heat treatment equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] 1. Production steps:

[0016] 1. Cast high-quality ADI material wheel billets:

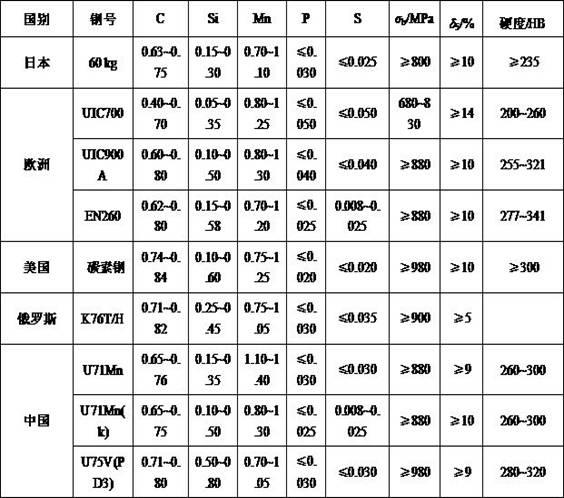

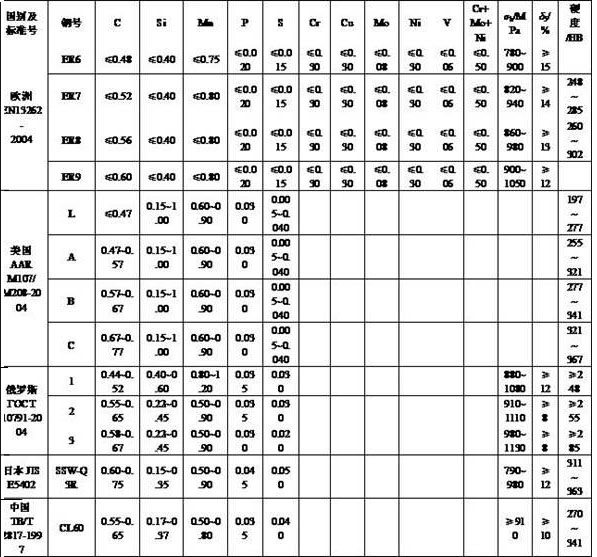

[0017] Select synthetic cast iron or high-purity nodular iron pig iron with carburized scrap steel as the main metal material for the production of the ADI (rare earth Aubey ductile iron) material wheel, strictly control the addition of alloying elements; melt molten iron in an intermediate frequency electric furnace, and blow argon Purify molten iron, take it out of the furnace at 1480-1560°C, and adopt spheroidization treatment and secondary inoculation treatment.

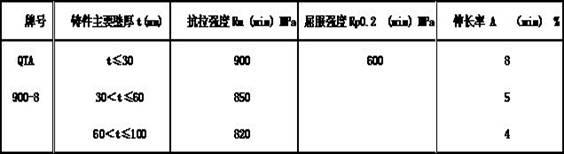

[0018] Addition of alloying elements (%)

[0019] C Si mn P S Mg Re (cerium Ce + yttrium Y) 3.1-3.9 2.0-3.0 <0.31 <0.03 <0.02 0.039-0.062 ≥0.02

[0020] 2. Analysis: The number of graphite balls of the formed ADI (rare earth Aubey ductile iron) material wheel castings is spheroidized grade 1-4 of GB9441-88; the graphite size is no thicker than GB9441-88 grade 5; the matrix structure The total...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com