High-strength steel sheet plated with zinc by hot dipping with excellent formability and process for producing the same

A technology of hot-dip galvanized steel sheet and manufacturing method, which is applied in the direction of manufacturing tools, hot-dip galvanizing technology, chemical instruments and methods, etc., can solve the problems of increased manufacturing cost and constraints, and achieve the effect of excellent formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0096] The following describes the embodiments of the present invention in more detail, but the present invention is not limited to the following embodiments, and additional changes are allowed without changing the gist of the present invention.

[0097] The steel of the chemical composition shown in Table 1 was smelted to obtain a cast piece, which was hot pressed, pickled, and cold rolled to form a 1.2 mm thick cold rolled steel sheet. Then, after heat treatment under the conditions shown in Tables 2 and 3, the weight per unit area was 50 / 50g / m using a galvanizing bath at 463°C. 2 The alloying treatment is performed to make the Fe% of the plating layer 9% by mass. The obtained steel sheet was subjected to temper rolling at 0.3%. In addition, the N content of the steel material is 0.0020-0.0060 mass%.

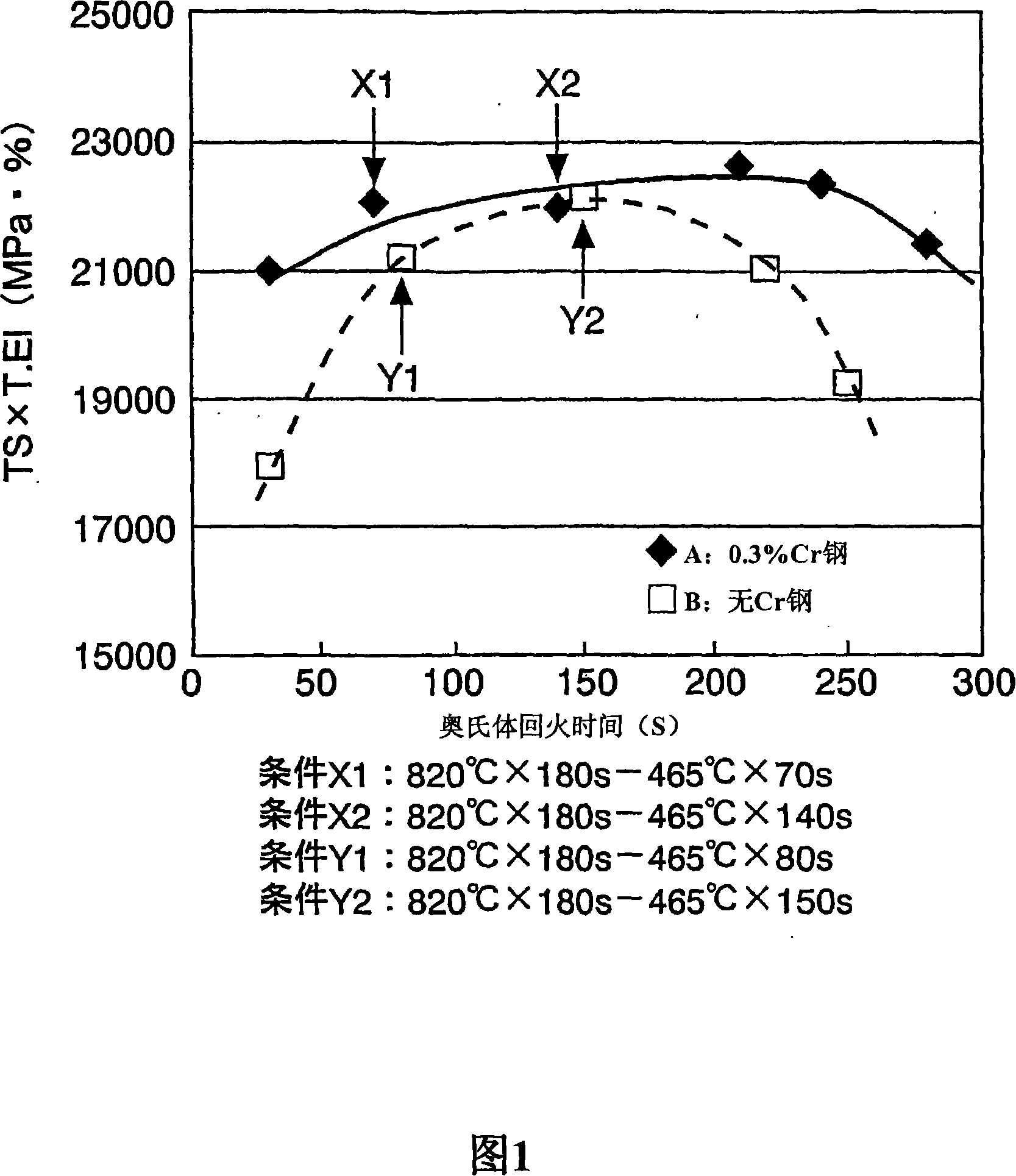

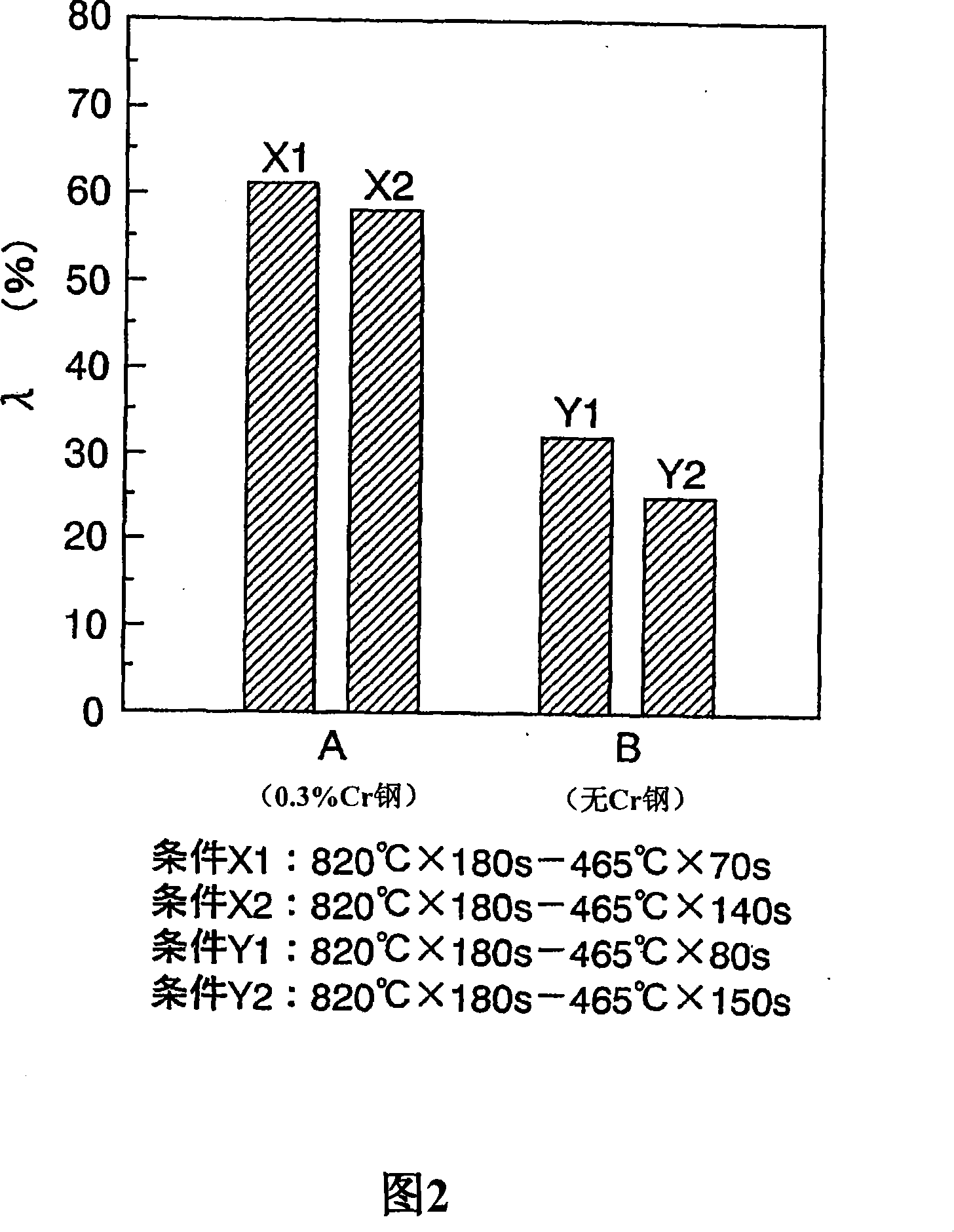

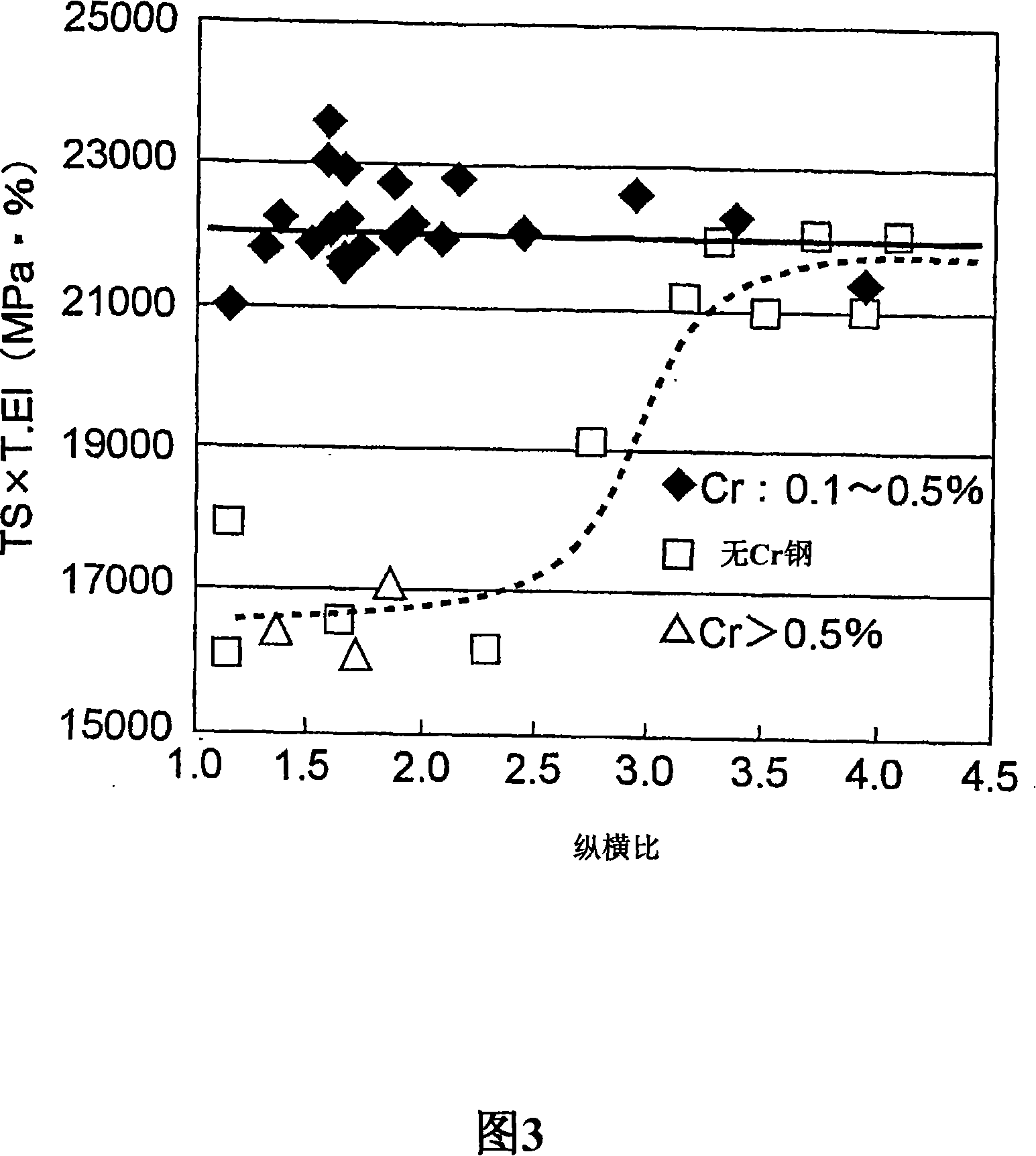

[0098] Observe 10 views of the structure of the cross section (plane parallel to the rolling direction) of the steel sheet with a scanning electron microscope (SEM) at 2000 times,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com