Austempering ductile iron (ADI) supercharged diesel engine six-cylinder crankshaft and production method

A technology of isothermal quenching ductile iron and its production method, which is applied in the field of metal materials, can solve problems such as being unable to meet the service conditions of supercharged diesel engines, and achieve the effects of light weight, obvious economic benefits, and convenient manufacture

Inactive Publication Date: 2010-06-02

长春怀林机械工程材料科技有限公司

View PDF0 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0024] The purpose of the present invention is to provide a six-cylinder crankshaft of an austempered ductile iron (ADI) supercharged diesel engine and its productio

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the class of metal materials. After a supercharged technology is used for a diesel engine, the load born by a crankshaft is improved by 45-67 percent. The fatigue property of ordinary ball iron cannot meet the requirement of service and is replaced by alloy steel. The invention provides an austempering ductile iron (ADI) supercharged diesel engine six-cylinder crankshaft and a production method which both determine chemical constituents, particularly determine the addition of alloying elements, propose definite requirements on the percent of spheroidization and the number of graphite pebbles and also determine the parameter of an isothermal quenching process. After quenching, the deformation of the six-cylinder crankshaft is controlled within a certain range, which is a key measure of the method. A special heat treatment tire for quenching the six-cylinder crankshaft is designed so as to obtain a satisfactory result. The application of a crankshaft fillet rolling technology greatly improves the fatigue property of the six-cylinder crankshaft. The invention makes a pioneering contribution to manufacturing the supercharged diesel engine six-cylinder crankshaft by the ADI and greatly reduces the production cost of the six-cylinder crankshaft.

Description

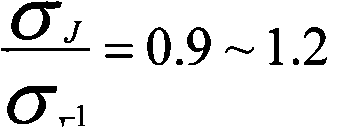

technical field [0001] The invention relates to metal materials, in particular to an austempering ductile iron (ADI) supercharged diesel engine six-cylinder crankshaft and a production method. Background technique [0002] After the diesel engine adopts supercharging technology, the load on the crank bearing increases by 45%-67%. The fatigue performance of ordinary ductile iron can no longer meet the service requirements, and it is facing the trend of being replaced by alloy steel. The fatigue performance of ductile iron is significantly improved after austempering, so that the ductile iron crankshaft can continue to be used. [0003] 1. Requirements for fatigue strength of crankshaft materials for supercharged diesel engines [0004] The application of supercharging technology has significantly improved the performance of diesel engines, and supercharging diesel engines has become an important direction for the development of diesel engines. In a diesel engine, the cranks...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C37/10B22D1/00C21D5/00

Inventor 王怀林刘光华曾艺成

Owner 长春怀林机械工程材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com