Spring structure for wheel suspensions in motor vehicles

A technology of spring structure and wheel suspension, applied in the direction of vehicle spring, suspension, elastic suspension, etc., can solve problems such as very crowding and problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

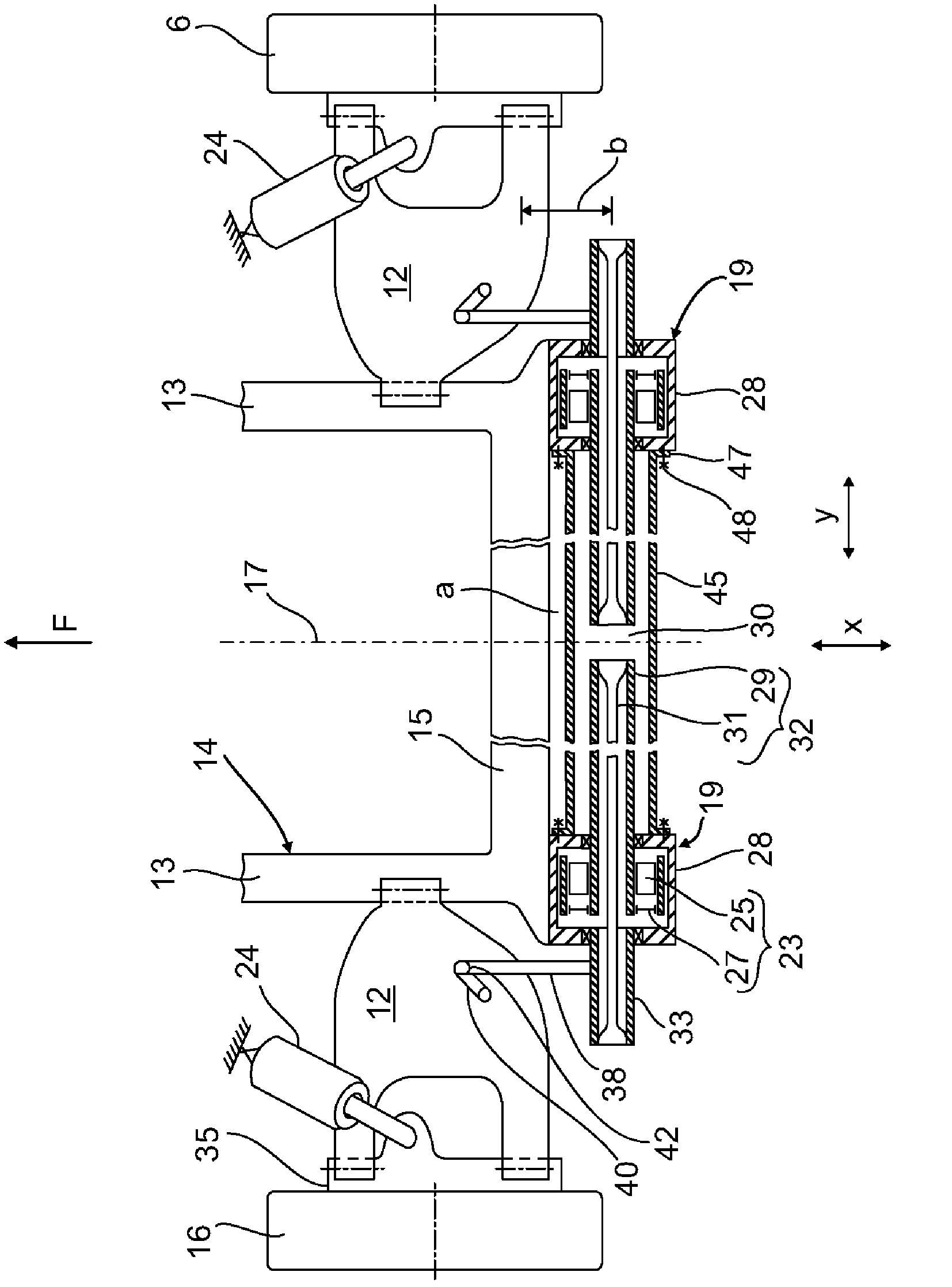

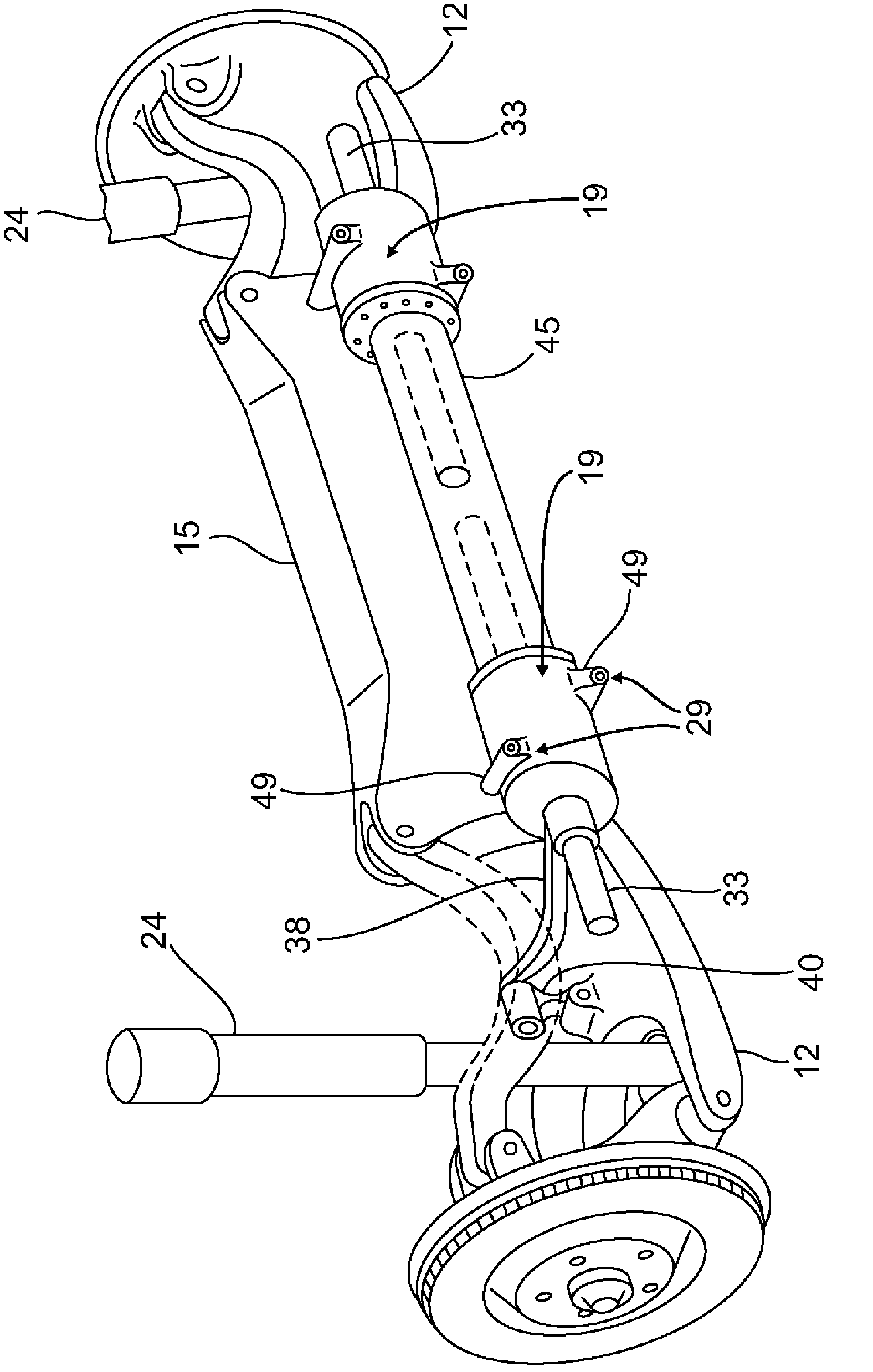

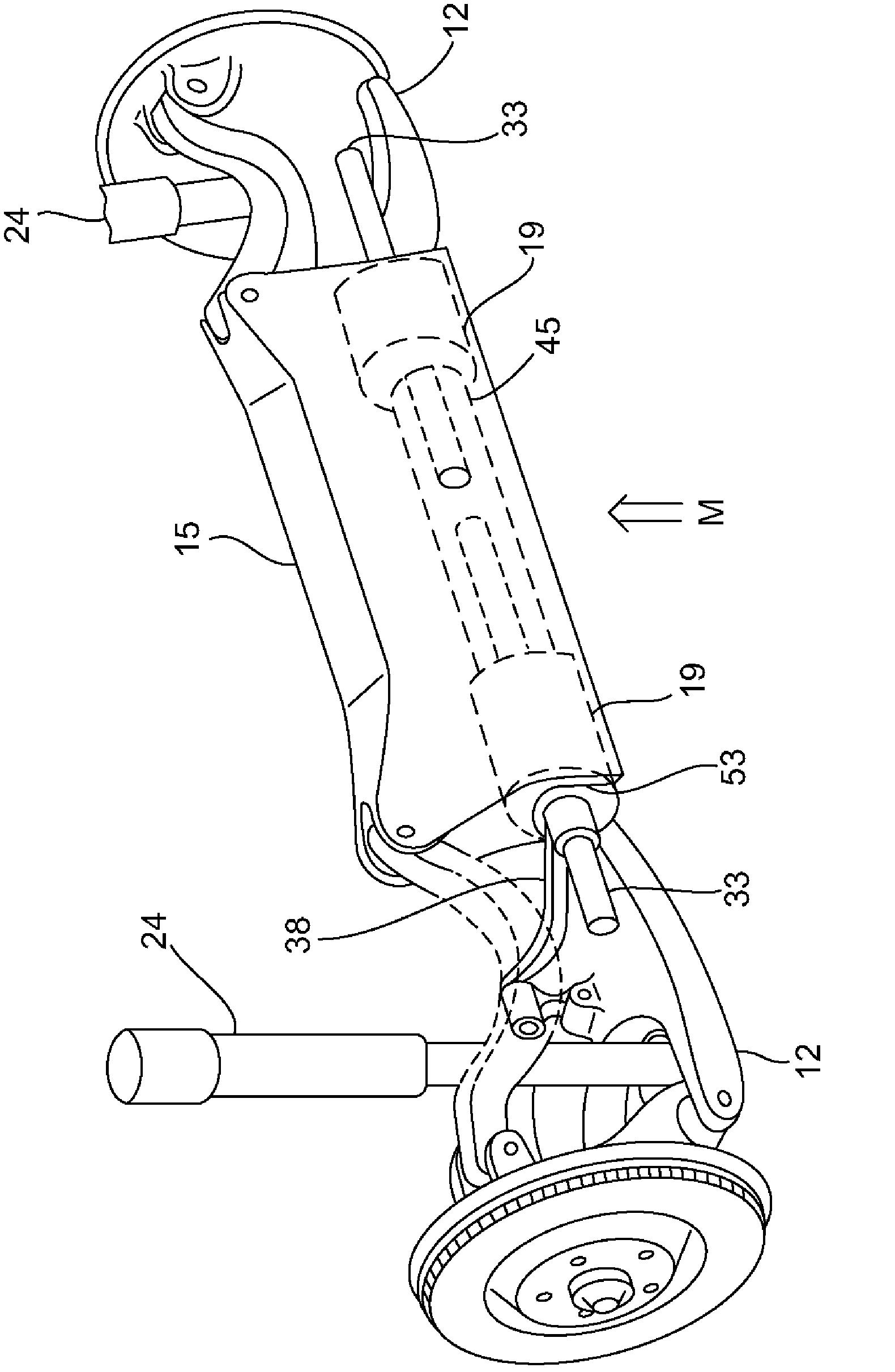

[0020] exist figure 1 The lower planes of the left and right wheel suspensions for the rear axle of a motor vehicle are shown in FIG. On the auxiliary frame 14 and on the other hand is articulated on the schematically shown hub carrier 35 for the rear wheel 16 . The transverse guide arm of the upper part of guiding hub bracket 35 is in figure 1 not visible in the , but only in the figure 2 shown roughly.

[0021] exist figure 1 The wheel suspensions for the left and right rear wheels 16 shown in FIG. figure 1 with 2 not shown in according to figure 1 The subframes 14 each have two lateral side members 13 and a rear cross member 15 in the vehicle longitudinal direction x and are fastened in a manner not shown to the body of the motor vehicle. As already indicated above, the wheel suspensions for the left-hand and right-hand rear wheels are designed mirror-symmetrically with respect to the vehicle center plane 17 .

[0022] If according to figure 1 It follows further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com