Fiber-based non-woven biodegradable ureteral stent tube and preparation method thereof

A ureteral stent tube and a biodegradable technology are applied in the field of fiber-based non-woven biodegradable ureteral stent tube and its preparation field, which can solve problems such as ureteral obstruction, achieve good biocompatibility, good product identity, and high economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of fiber raw materials: PGA and PLGA (PGA:PLA=90:10) chip raw materials, prepared by melt spinning process PGA (30-100dtex / 8-24f) multifilament fiber and PLGA (30-100dtex / 8-24f) Multifilament fiber; spinning is carried out on a micro spinning machine, and the spinning temperature is 255°C.

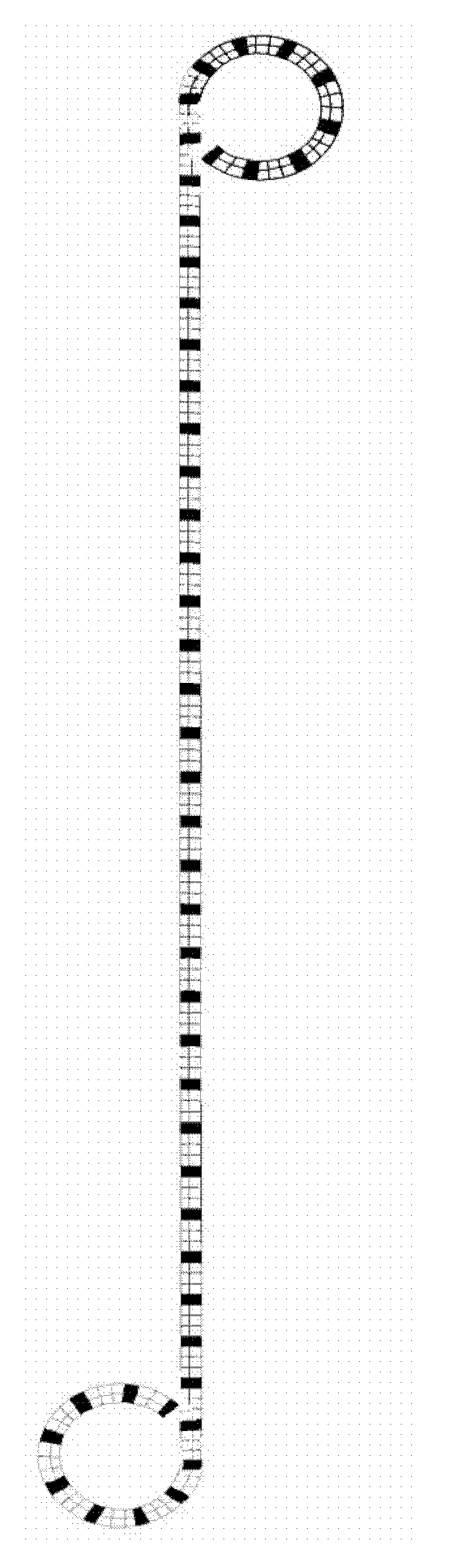

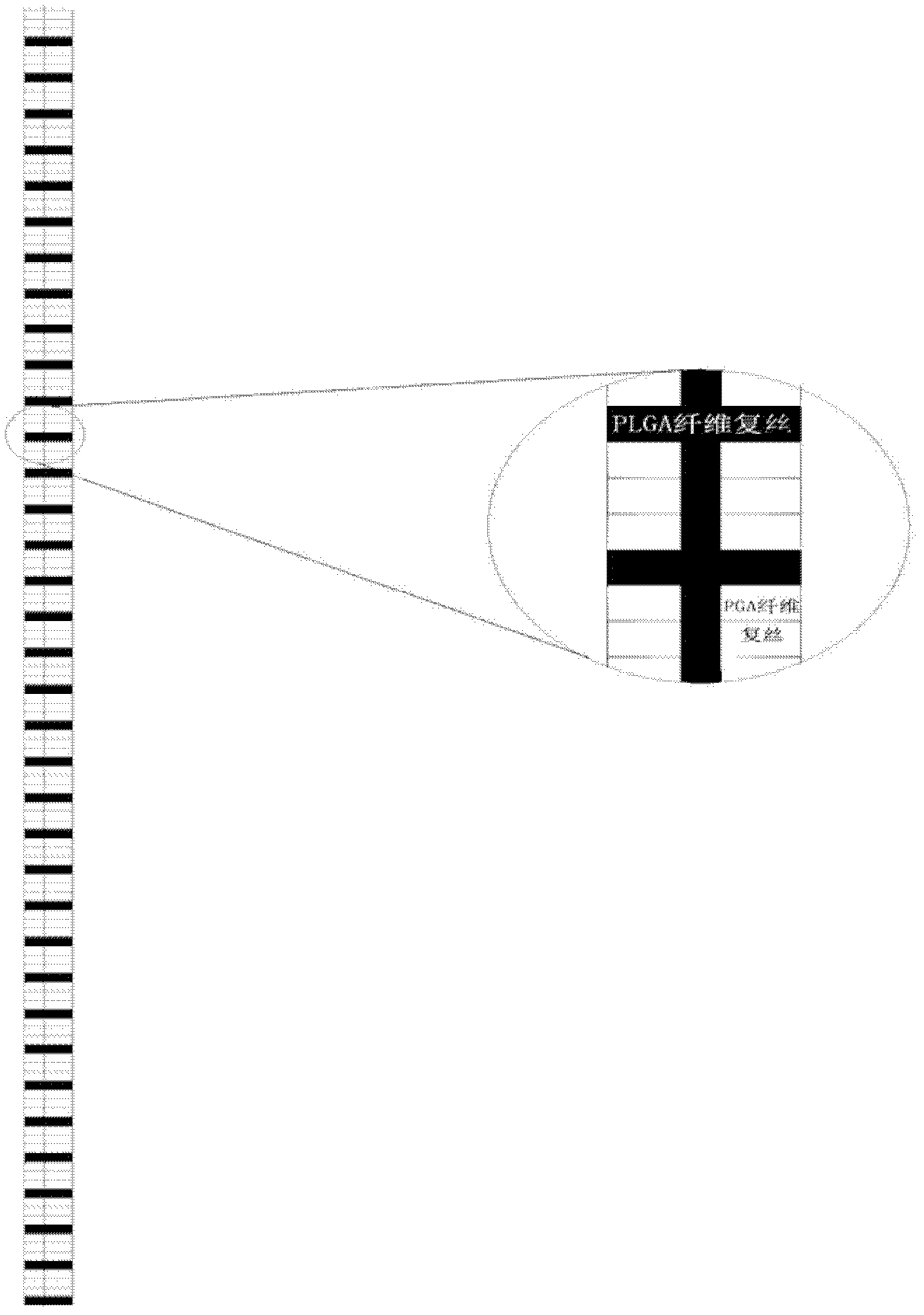

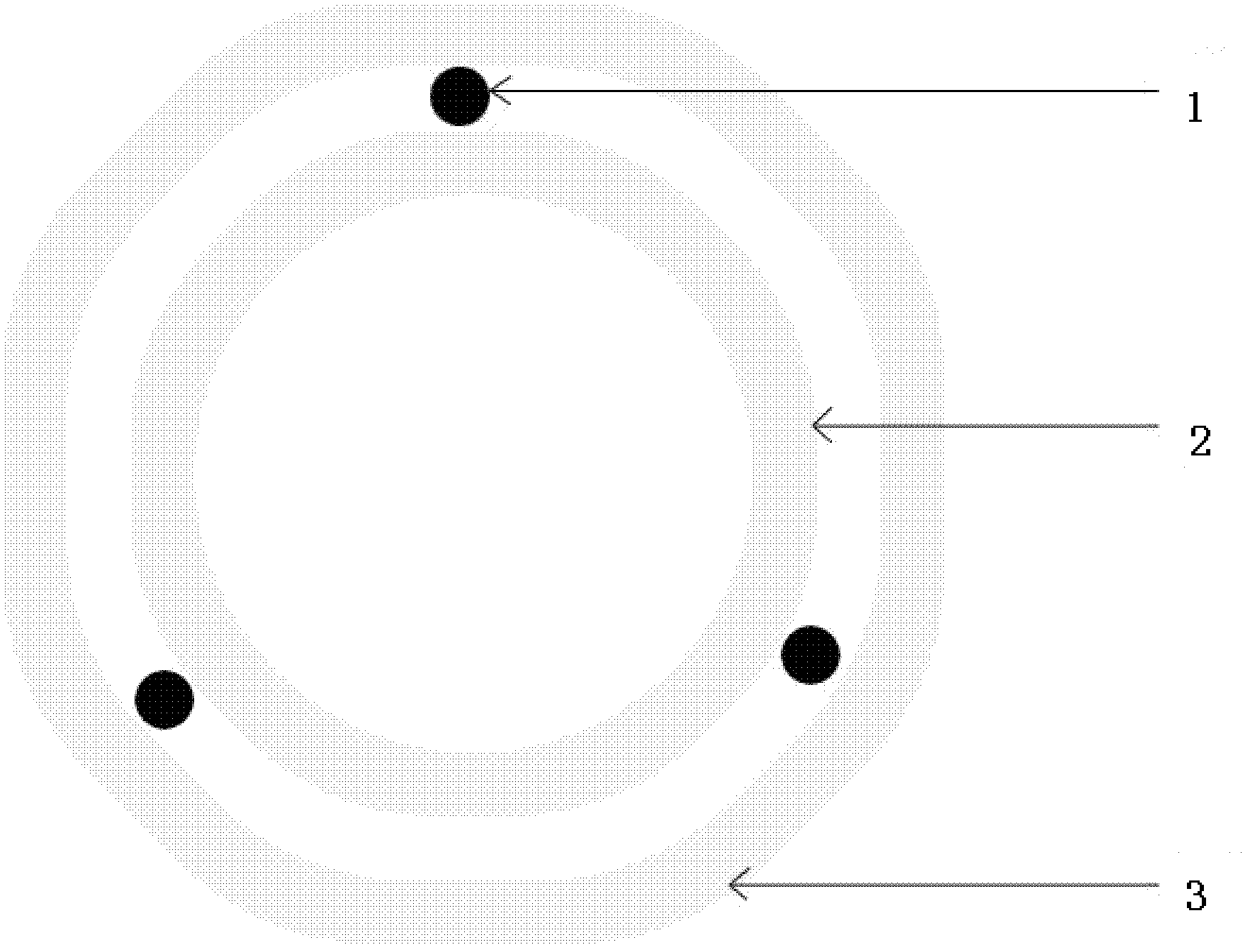

[0032] First arrange PLGA (30dtex / 8f) and PGA (30dtex / 8f) multifilament fibers in parallel in 1:3, as figure 2 , 3, wound in parallel on a mandrel with a diameter of 1.0mm, and then placed a PLGA fiber multifilament at intervals of 120° in the longitudinal axis direction, and wound a layer on its outer layer according to the above method. The total length is 16.0cm; set it in a vacuum oven at 210°C for 1min, and then remove the support tube layer from the mandrel; insert a 3.0cm-long tube with a diameter smaller than the inner diameter of the support tube and a length of 3.0cm at both ends of the preliminarily shaped support tube. The mandrel is wrapped around a polyt...

Embodiment 2

[0036] Preparation of fiber raw materials: PGA and PLGA (PGA:PLA=95:5) chip raw materials (wherein adding barium sulfate with a mass ratio of 10-20%), prepare PGA (30-100dtex / 8-24f) by melt spinning process And PLGA (30-100dtex / 8-24f) multifilament fibers; spinning is carried out on a micro-spinning machine, and the spinning temperature is 255°C. First arrange PLGA (30dtex / 8f) and PGA (30dtex / 8f) multifilament fibers in parallel at 1:5, such as figure 2 , 3 , wound in parallel on a mandrel with a diameter of 3.0mm, and then placed a PLGA fiber multifilament at intervals of 90° in the longitudinal axis direction, and wound a layer on its outer layer according to the above method. The total length is 44.0cm; set it in a vacuum oven at 210°C for 15 minutes, and then remove the stent tube layer from the mandrel; insert a 9.5cm long tube with a diameter smaller than the inner diameter of the stent tube at both ends of the preliminarily shaped stent tube. The mandrel is wrapped a...

Embodiment 3

[0040] Preparation of fiber raw materials: PGA and PLGA (PGA: PLA = 60: 40) chip raw materials (wherein adding barium sulfate with a mass ratio of 30%), prepare PGA (30-100dtex / 8-24f) and PLGA by melt spinning process (30-100dtex / 8-24f) multifilament fiber; the spinning is carried out on a micro-spinning machine made by Shanghai Tianqing Biological Materials Co., Ltd., and the spinning temperature is 255°C.

[0041] First arrange PLGA (30dtex / 8f) and PGA (30dtex / 8f) multifilament fibers in parallel in 1:5 on the braiding machine, such as figure 2 , 3 , wound in parallel on a mandrel with a diameter of 5.8mm, and then placed a PLGA fiber multifilament at intervals of 90° in the longitudinal axis direction, and wound a layer on its outer layer according to the above method. Then install the above method to co-wind 4 layers of fiber multifilament. The total length is 65.0cm; shape it in a vacuum oven at 210°C for 30 minutes, and then remove the stent tube layer from the mandre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com