Sewing machine with stitch breaking device

A sewing machine with thread cutting technology, which is applied in the field of sewing machines, can solve the problems of blade edge loss, heavy thread cutting load, minimum diameter limit, etc., achieve the effect of reducing the number of parts and assembly man-hours, expanding the scope of application, and realizing the effect of small diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

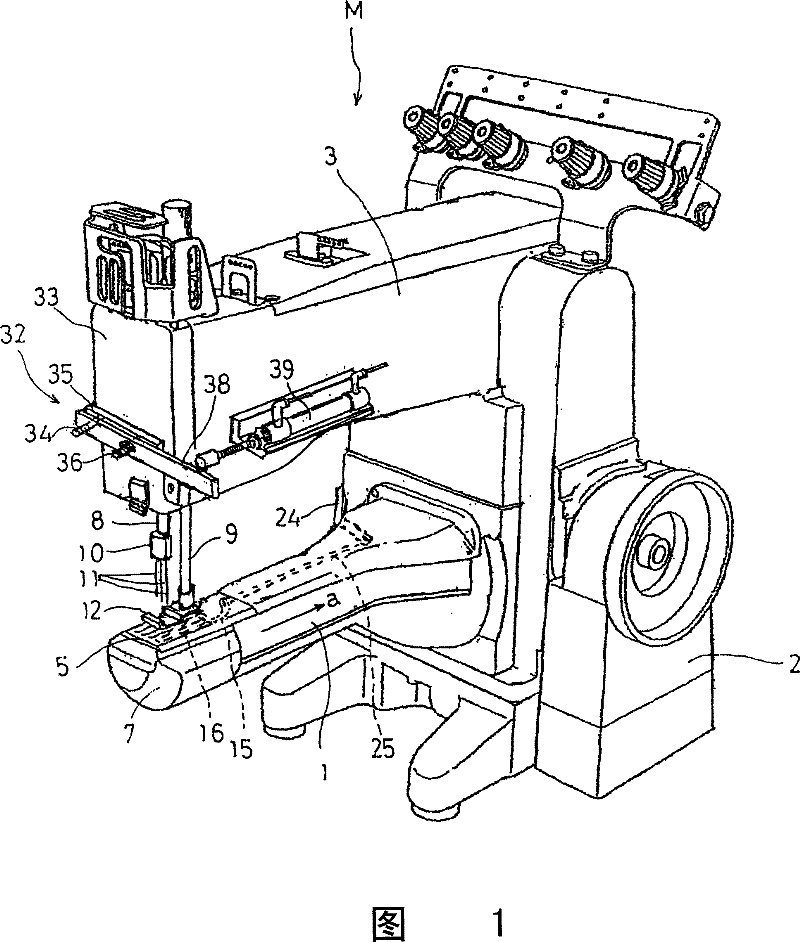

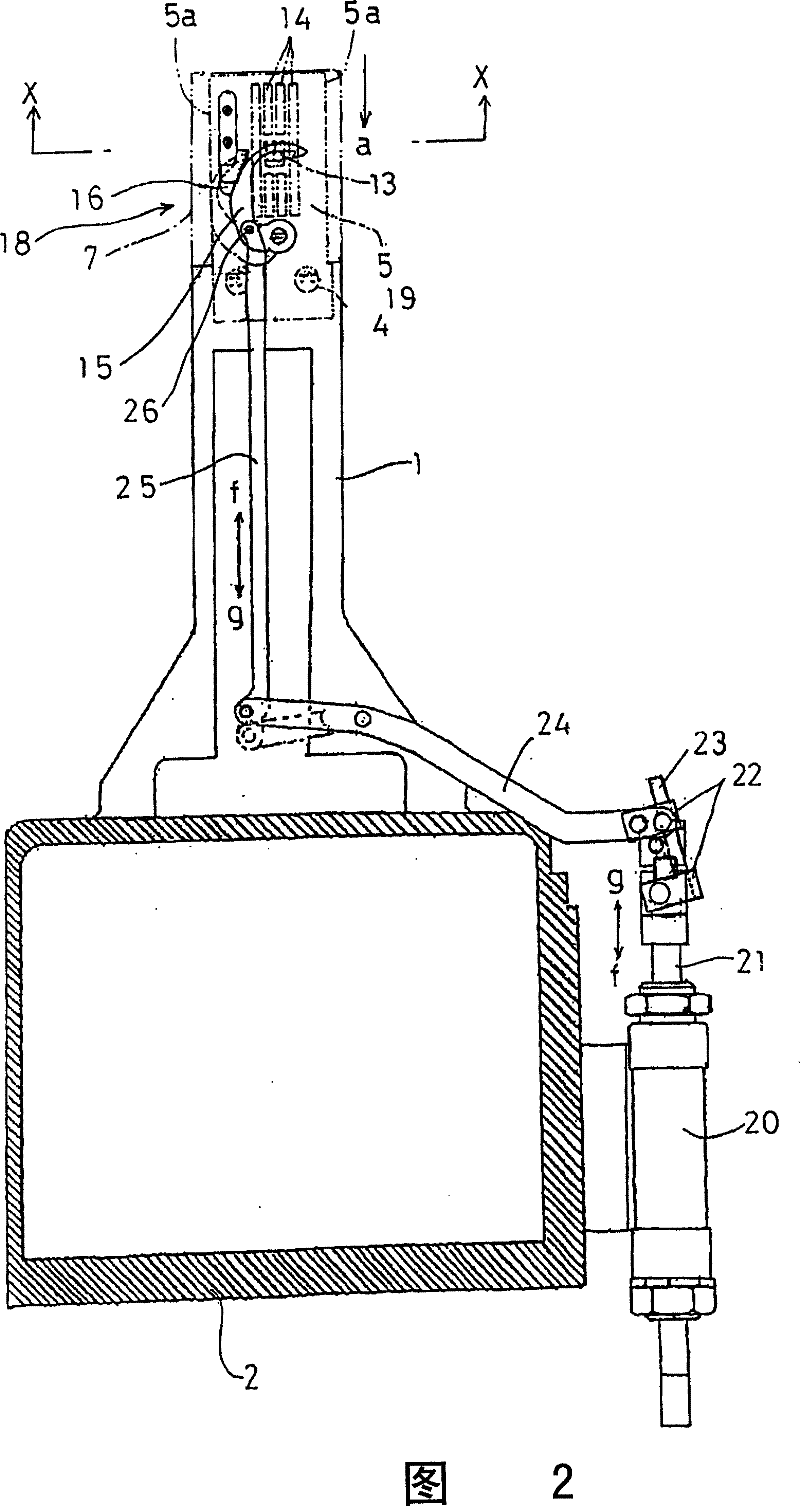

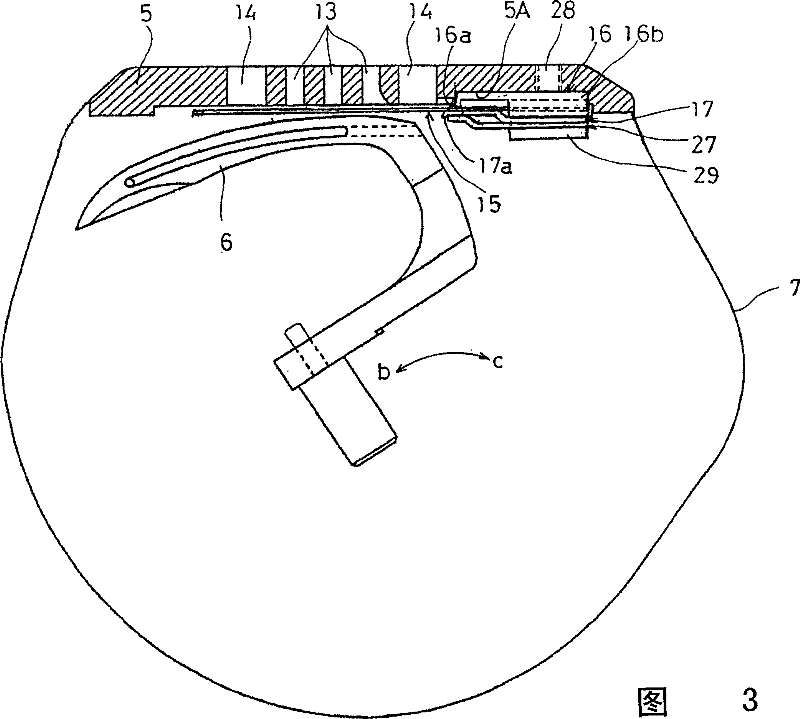

[0027] Figure 1 ~ Figure 3 The illustrated 3-needle cylinder sewing machine M faces forward from the lower part of the sewing machine base 2, and has a sewing machine main shaft, a needle drive mechanism, and a pressing drive mechanism extending therein (because these mechanisms are well known, the detailed structure and description thereof are omitted. ) of the sewing machine arm portion 3 and its cylindrical base portion 1, on the free end portion of the cylindrical base portion 1, the needle plate 5 is fixed by the screw 4, and at the same time, the bottom of the needle plate 5 is installed with the Cloth feeding direction (sewing direction) a intersects (orthogonal) the looper 6 and the looper driving mechanism (because these mechanisms are well known, so the detailed structure and description thereof are omitted) on the b-c direction that crosses (orthogonal), and A free end portion of the cylindrical base 1 is provided with a base cover 7 detachable from the front end t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com