Method for preparing double-catalysis center molecular sieve nucleocapsid material with hydrothermal/solvent-thermal system

A technology of molecular sieve and solvothermal, which is applied in the field of preparation of molecular sieve core-shell materials, achieves the effects of tight combination, reduced catalytic cost, and improved reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

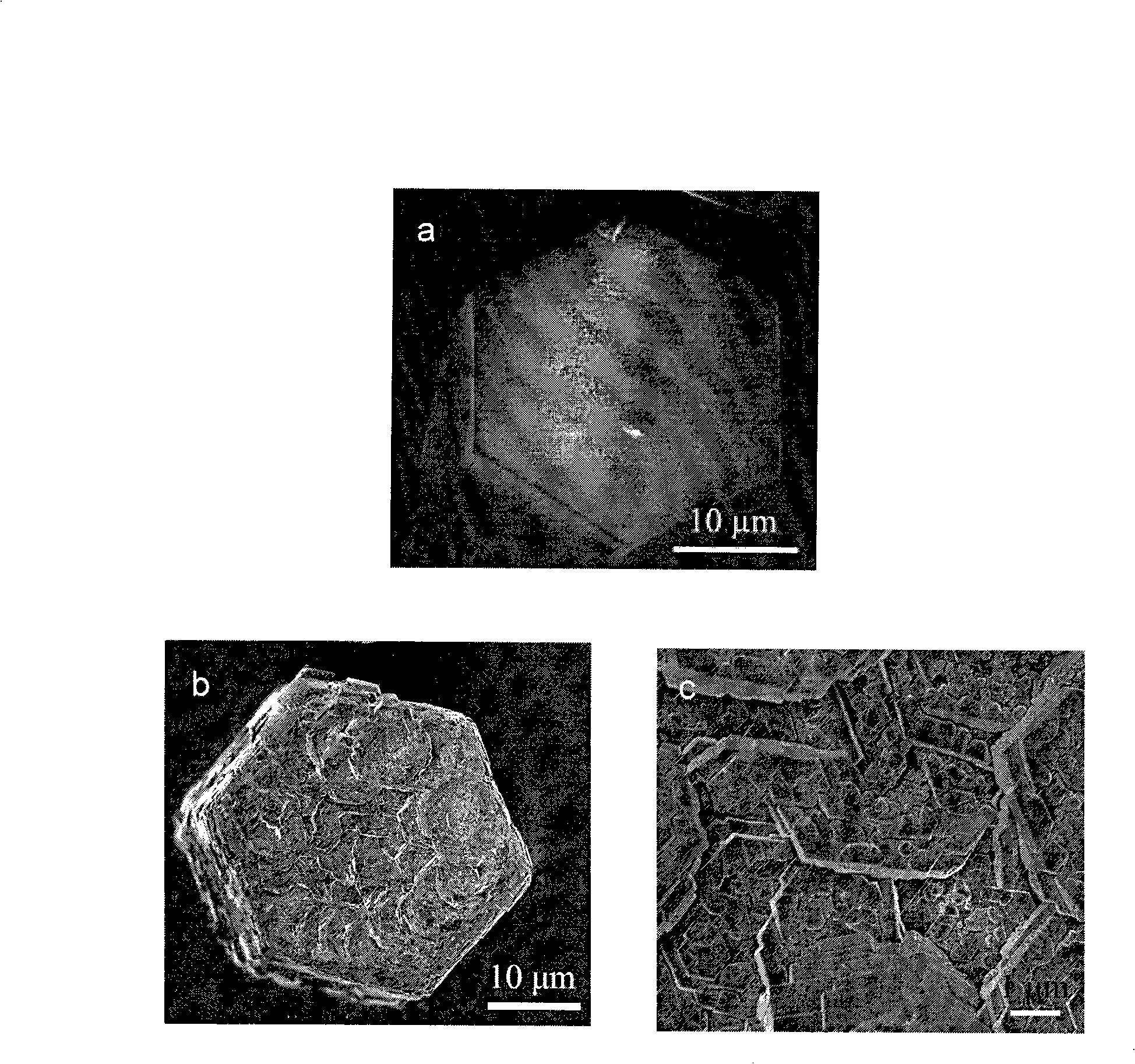

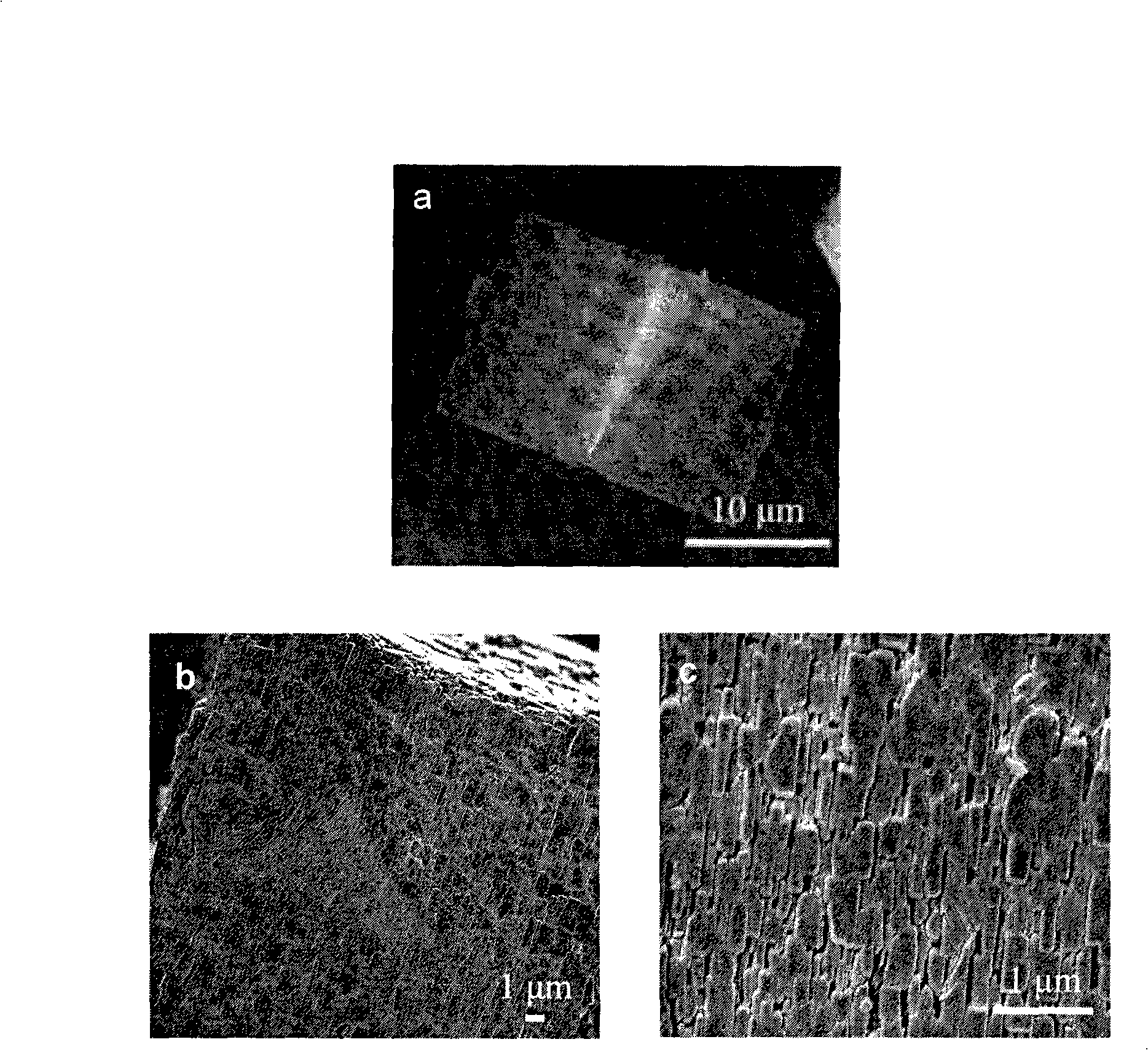

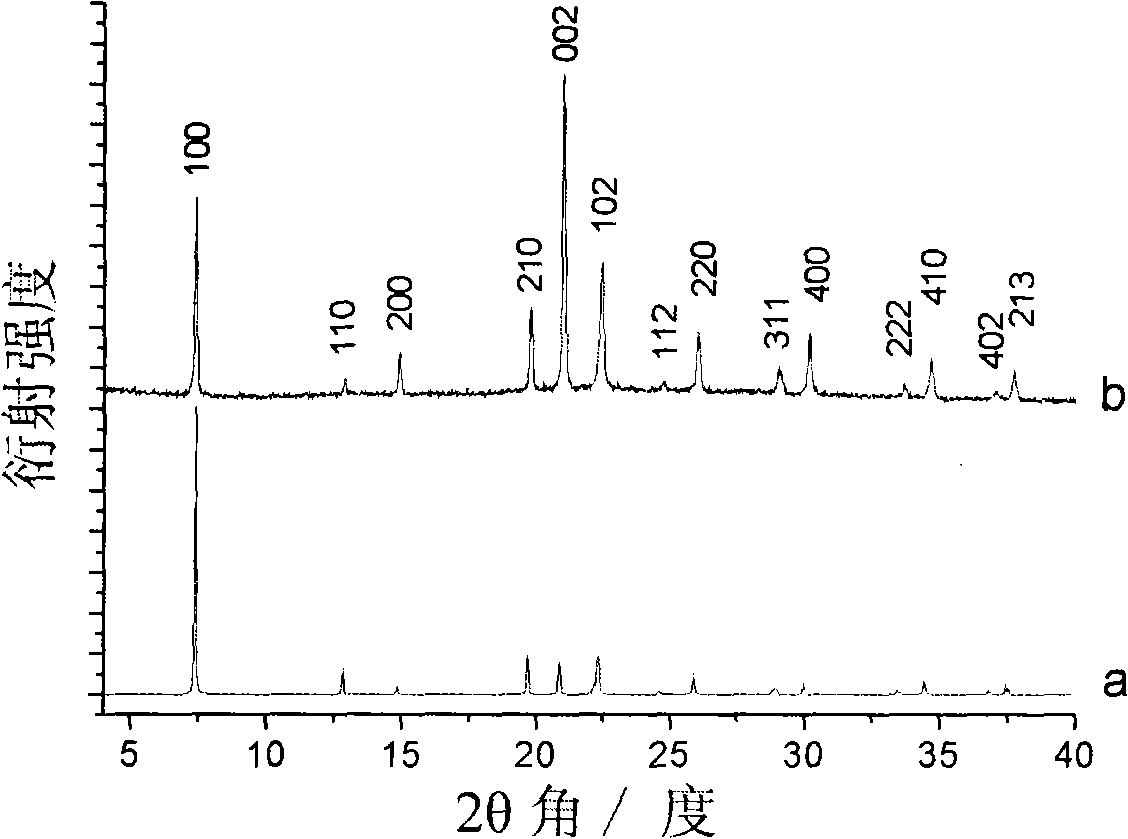

[0066] Cr-AFI crystals with a size of 20 microns are used as the core part of the molecular sieve core-shell material, and lamellar Ti-AFI nanocrystals are used as the shell part.

[0067] 0.5 g of carefully ground aluminum isopropoxide (Al(OPr i ) 3 ) dissolved in polyethylene glycol (pEG) (5mL) and water (H 2 O) (5mL) mixed system, add phosphoric acid (H 3 PO 4, 85%) (0.215mL), triethylamine (TEA) (0.273mL), chromium chloride (CrCl 3 ·6H 2 O) (0.0391 g), stirred at room temperature for 10 hours to obtain a synthetic sol of Cr-AFI, crystallized at 180 ° C for 12 hours, and synthesized transition metal Cr-doped AFI nuclear molecular sieve crystals with a particle size of 20 to 30 μm (SEM scanning electron microscope). , as the core part of the core-shell material. The substitution amount of Cr was determined to be 1% by ICP, and Cr entered into the AFI skeleton by ultraviolet-visible spectroscopy.

[0068] The prepared Cr-AFI nuclear molecular sieve crystals were ultras...

Embodiment 2

[0074] The Cr-AFI crystal with a size of 20 microns is used as the core part of the molecular sieve core-shell material, and the lamellar V-AFI nanocrystal is used as the shell part.

[0075] Finely ground aluminum isopropoxide (Al(OPr i ) 3 ) 0.5 g dissolved in polyethylene glycol (pEG) (5 mL) and water (H 2 O) (5mL) mixed system, add phosphoric acid (H 3 PO 4 , 85%) (0.215mL), triethylamine (TEA) (0.273mL), chromium chloride (CrCl 3 ·6H 2 O) (0.0391 g), stirred at room temperature for 10 hours to obtain a synthetic sol of Cr-AFI, crystallized at 180 ° C for 12 hours, and synthesized transition metal Cr-doped AFI molecular sieve crystals with a particle size of 20 to 30 μm, as core-shell materials. nuclear part. The substitution amount of Cr was determined to be 1% by ICP, and Cr entered into the AFI skeleton by ultraviolet-visible spectroscopy.

[0076] The prepared Cr-AFI molecular sieve crystals were ultrasonically washed three times with deionized water, and then d...

Embodiment 3

[0081] The Fe-AFI crystal with a size of 20 microns is used as the core part of the molecular sieve core-shell material, and the lamellar Ti-AFI nanocrystal is used as the shell part.

[0082] Finely ground aluminum isopropoxide (Al(OPr i ) 3 ) 0.5 g dissolved in polyethylene glycol (pEG) (5 mL) and water (H 2 O) (5mL) mixed system, add phosphoric acid (H 3 PO 4 , 85%) (0.215mL), triethylamine (TEA) (0.273mL), ferric chloride (FeCl 3 ) (0.0243 g), stirred at room temperature for 10 hours to obtain a sol of Fe-AFI, crystallized at 180 ° C for 12 hours, and synthesized transition metal Fe-doped AFI molecular sieve crystals with a particle size of 20-30 μm as the core part of the core-shell material .

[0083] The prepared Fe-AFI molecular sieve crystals were ultrasonically washed three times with deionized water, and then dried in an oven at 50°C.

[0084] Finely ground aluminum isopropoxide (Al(OPr i ) 3 ) 0.3 g dissolved in polyethylene glycol (pEG) (7mL) and water (H ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com