Tin-tungsten co-doped vanadium dioxide powder and preparation method thereof

A vanadium dioxide and co-doping technology, which is applied in the field of nanomaterials and nanometers, can solve the problems of cumbersome process, low efficiency, and high energy consumption, and achieve the effects of high controllability, simple and easy operation of the process, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A kind of preparation method of tin-tungsten co-doped vanadium dioxide powder, the preparation method of described tin-tungsten co-doped vanadium dioxide powder comprises the following steps:

[0025] Step 1): dissolving the soluble vanadium salt, dissolving the soluble vanadium salt in deionized water, stirring evenly at room temperature to obtain a stable solution, the soluble vanadium salt is one or more of the water-soluble vanadium salts, including: vanadyl sulfate , vanadyl oxalate, etc.;

[0026] Step 2): Prepare the precipitation dispersion of the solution in step 1), react the vanadium-containing solution prepared in step 1) with the precipitating agent in deionized water to obtain a suspension, centrifuge and wash to remove impurities, and disperse the obtained precipitate in deionized water ionized water. The precipitating agent is one or more of water-soluble alkaline reagents, including: ammonia water, sodium hydroxide, potassium hydroxide, sodium bicarbon...

Embodiment 1

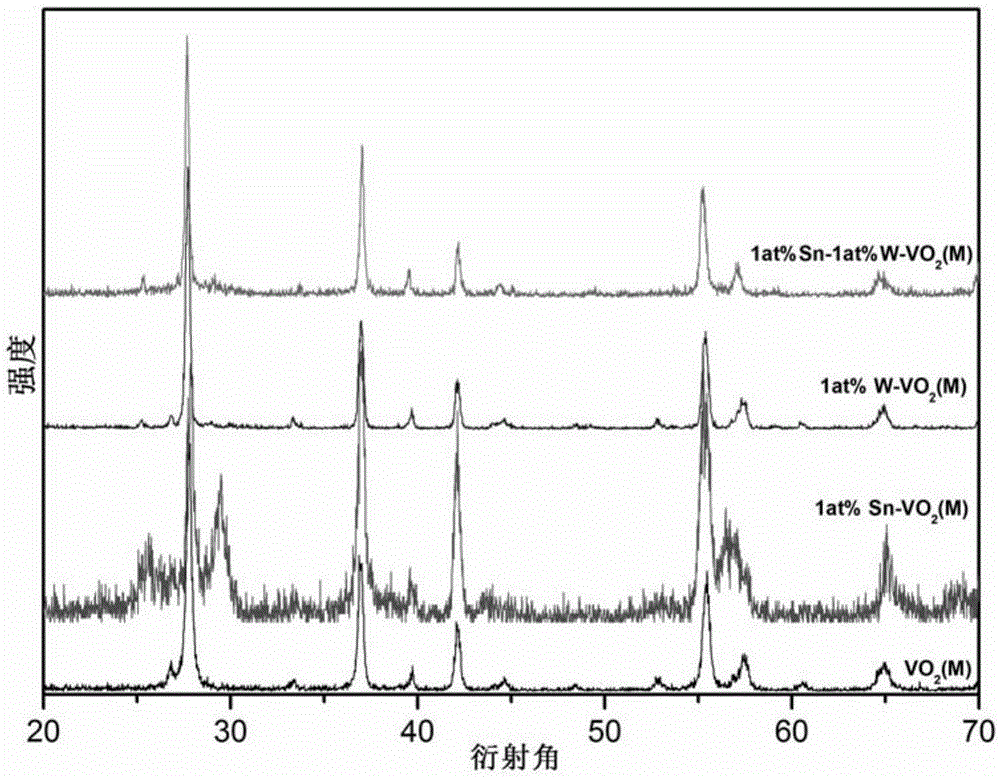

[0030] like figure 1 , 2 As shown, weigh 1.14g of vanadyl sulfate powder and dissolve it in 60mL of deionized water, stir evenly at room temperature, and prepare a blue transparent solution. Will pre-prepared VOSO 4 Solution and ammonia water were prepared by co-titration method to obtain VO(OH) 2 Precipitation, washing with deionized water and centrifugation were repeated three times, and the resulting precipitate was dispersed in 60 mL of deionized water.

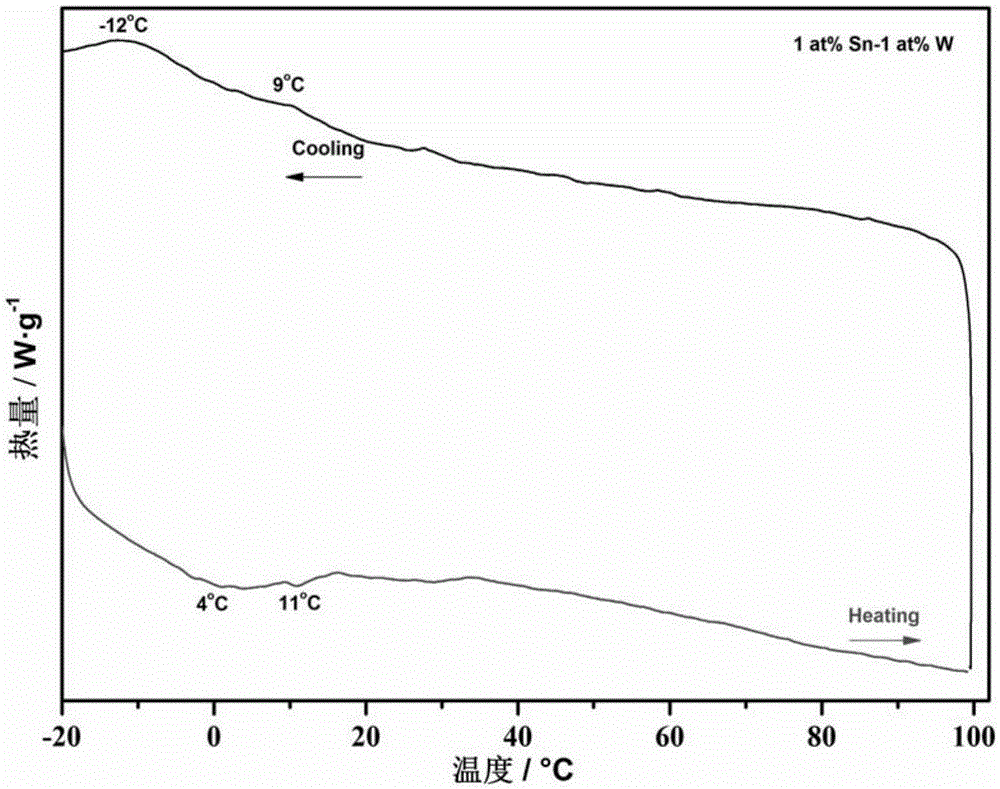

[0031] According to the molar ratio, add 0.63g oxalic acid, 0.5mL hydrogen peroxide, 0.0304g ammonium tungstate and 0.0859g stannous sulfate to VO(OH) 2 Stir evenly in the dispersion liquid, transfer to a hydrothermal kettle, and conduct a hydrothermal reaction at 280°C for 36 hours. After the hydrothermal kettle was naturally cooled to room temperature, the obtained crude product was repeatedly washed and centrifuged with deionized water and absolute ethanol, and then dried in a vacuum oven at 60°C for 6 hours to obt...

Embodiment 2

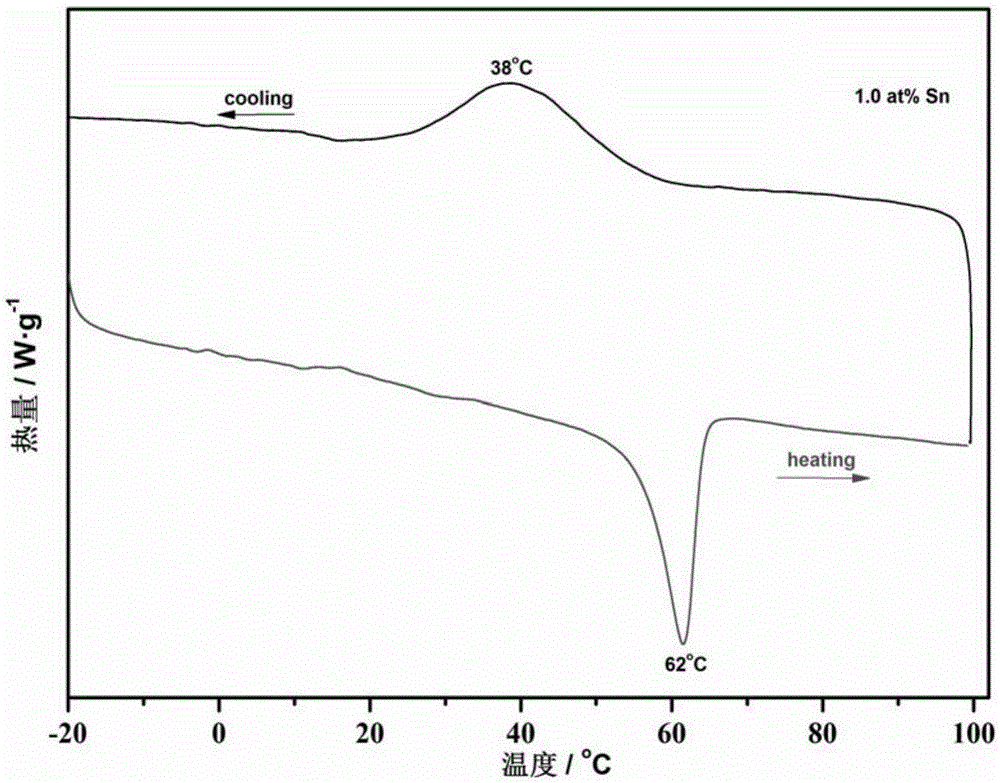

[0033] like figure 1 , 3 As shown, weigh 1.14g of vanadyl sulfate powder and dissolve it in 60mL of deionized water, stir evenly at room temperature, and prepare a blue transparent solution. Will pre-prepared VOSO 4 Solution and ammonia water were prepared by co-titration method to obtain VO(OH) 2 Precipitation, washing with deionized water and centrifugation were repeated three times, and the resulting precipitate was dispersed in 60 mL of deionized water.

[0034] Add 0.63g oxalic acid, 0.5mL hydrogen peroxide and 0.0859g stannous sulfate to VO(OH) according to the molar ratio 2 Stir evenly in the dispersion liquid, transfer to a hydrothermal kettle, and conduct a hydrothermal reaction at 280°C for 36 hours. After the hydrothermal kettle was naturally cooled to room temperature, the obtained crude product was repeatedly washed and centrifuged with deionized water and absolute ethanol, and then dried in a vacuum oven at 60°C for 6 hours to obtain blue-black 1at%Sn-doped V...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com