Patents

Literature

65 results about "Oxyvanadium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

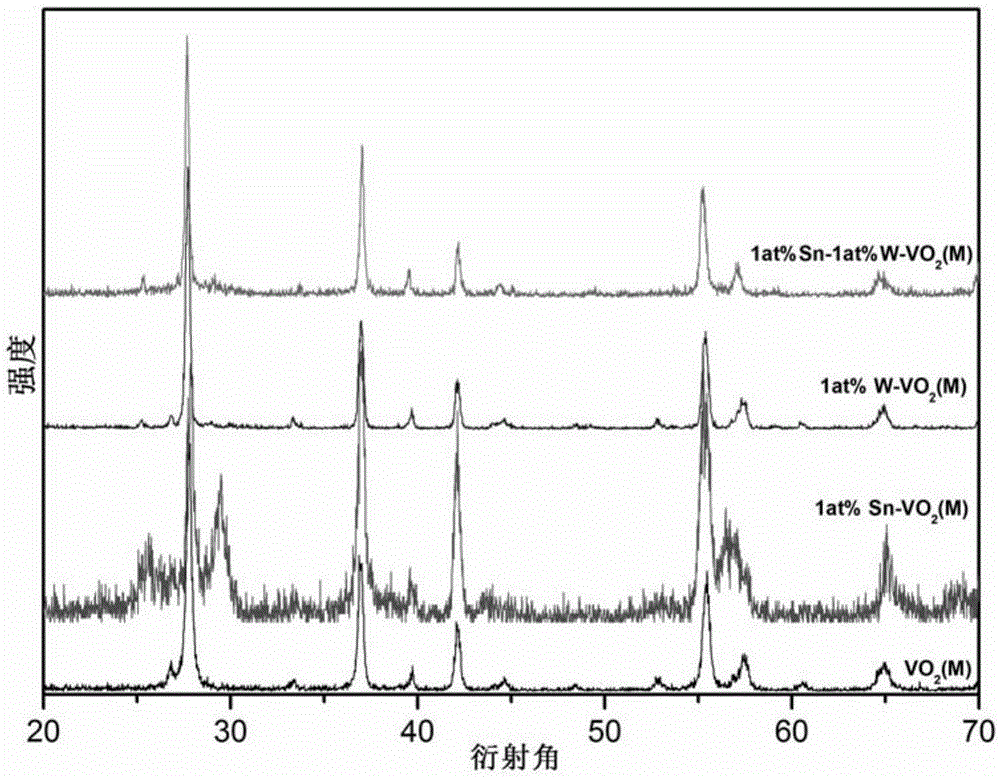

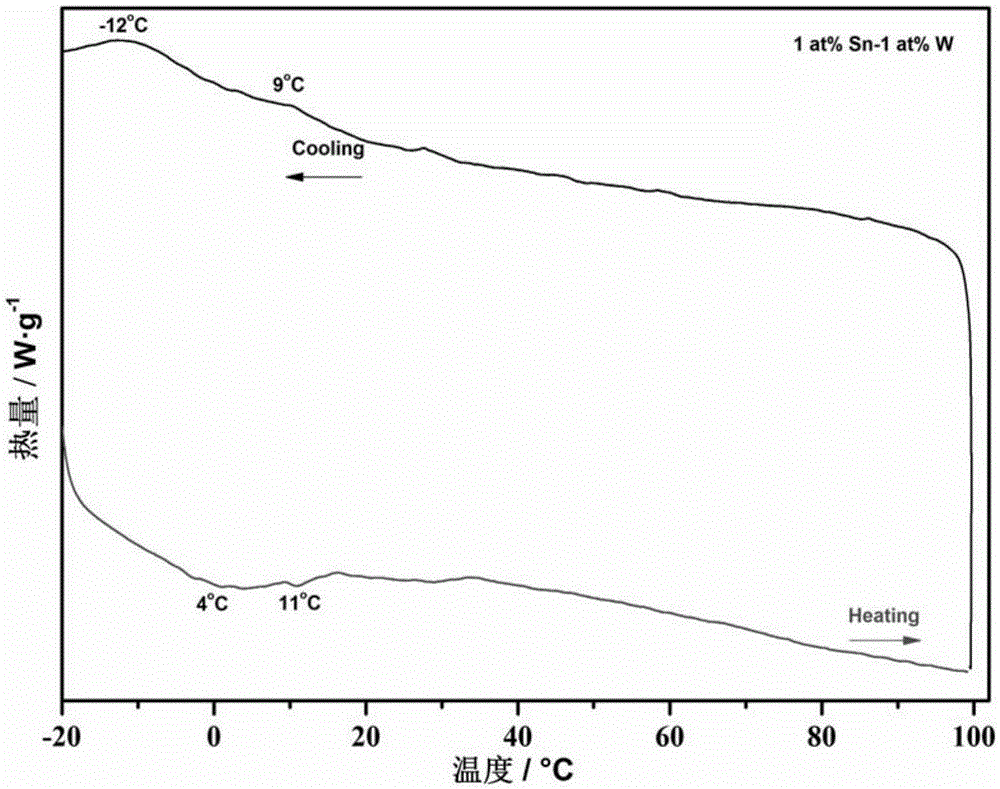

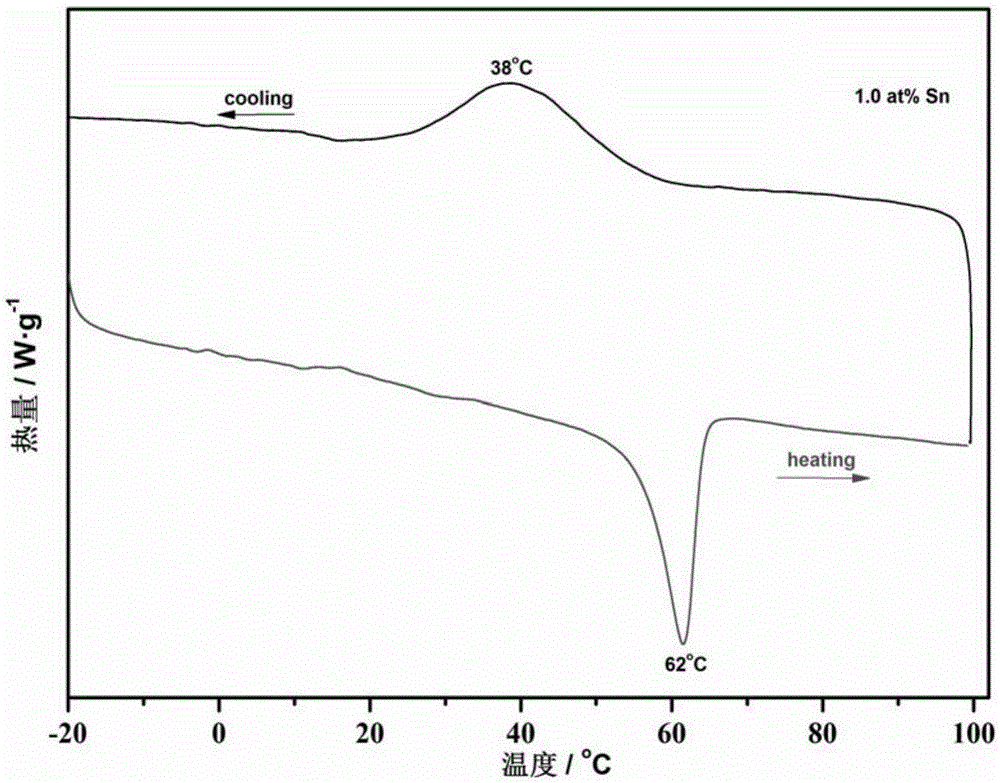

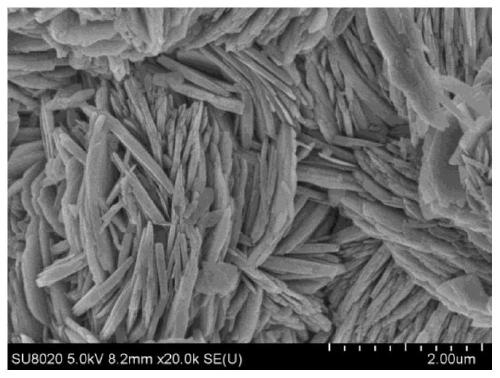

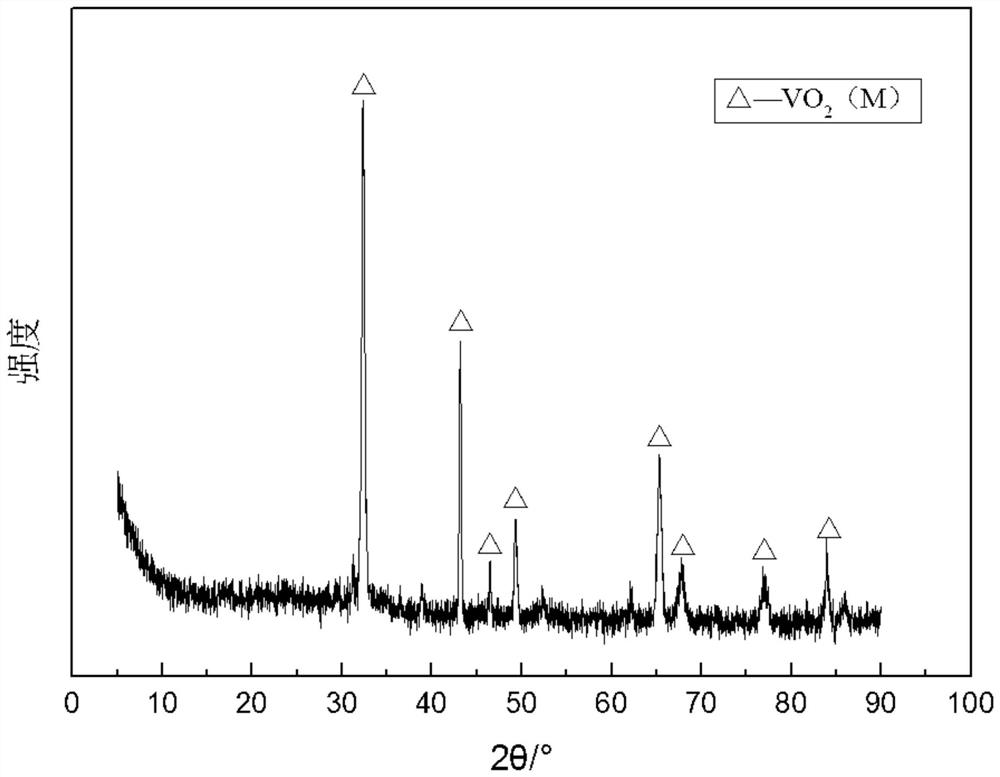

Tin-tungsten co-doped vanadium dioxide powder and preparation method thereof

InactiveCN105271408AGuaranteed purityLower phase transition temperatureTungsten oxides/hydroxidesVanadium oxidesVanadium dioxideCentrifugation

The invention provides a preparation method of tin-tungsten co-doped vanadium dioxide powder. The preparation method includes the steps that firstly, soluble vandic salt is dissolved and then reacts with precipitant to obtain a vanadium-sediment-containing intermediate, centrifugation, washing and diffusion are conducted, and vanadium-containing dispersion liquid is obtained; secondly, a tungsten source, a tin source, a needed oxidizing agent and a needed reducing agent are added to the dispersion liquid and evenly stirred, and the mixture is transferred into a hydrothermal kettle; the hydrothermal kettle is arranged at the temperature of 200-300 DEG C for a hydrothermal reaction for 6-72 h; after the hydrothermal reaction is completed, the product is centrifuged, washed and dried, and then the tin-tungsten co-doped vanadium dioxide powder is obtained. The preparation process is simple, cost is low, reproducibility is good, the controllable degree is high, the co-doped vanadium dioxide powder is directly prepared through a one-step hydrothermal method, and heat treatment or crystallization is not needed. The phase-transition temperature of VO2(M / R) nano-powder can be regulated through tin-tungsten co-doping.

Owner:UNIV OF SCI & TECH BEIJING

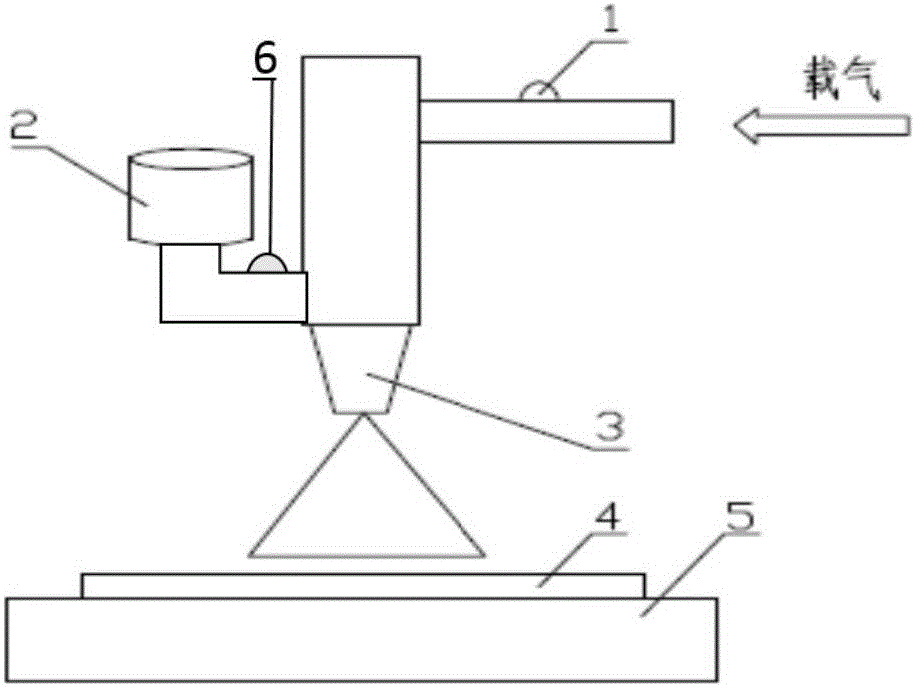

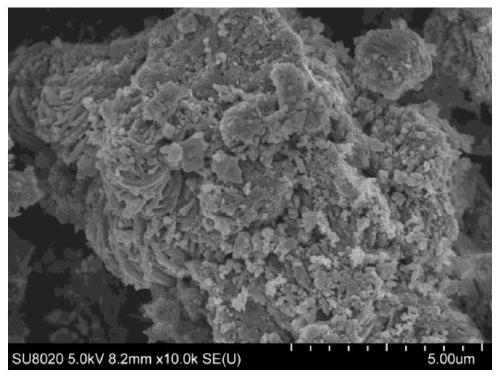

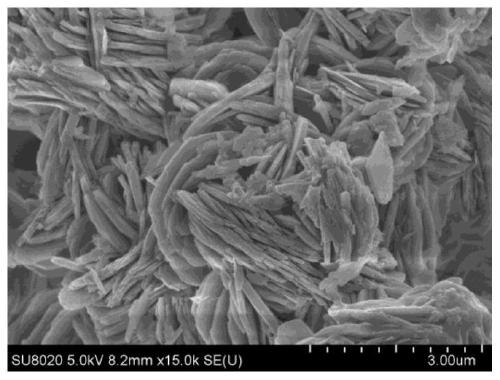

Preparation method of VO2(M) nano powder and film through spray pyrolysis

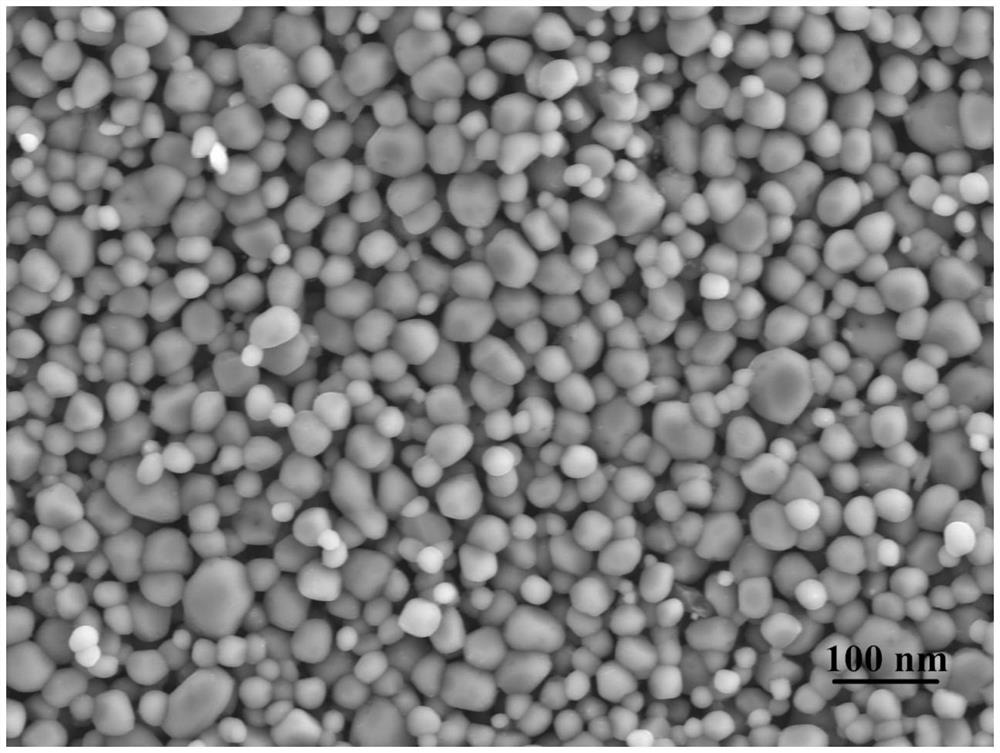

ActiveCN105819508AFast preparationImprove transmittanceMaterial nanotechnologyVanadium oxidesVanadium dioxideSpray pyrolysis

The invention relates to a preparation method of VO2(M) nano powder and film through spray pyrolysis. The preparation method comprises the following steps: adding ammonium meta-vanadate into a glycol solvent, heating and stirring to form a transparent and uniform precursor solution with a concentration of 0.02 to 1 mol / L finally, then atomizing the precursor into droplets by an atomizer, spraying the droplets to a heated substrate by carrier gas, decomposing precursors on the substrate, after the products deposit for a while, and collecting the products namely VO2(M) nano powder or film; wherein a doping agent is added during the preparation process of precursor so as to reduce the phase change temperature of vanadium dioxide to room temperature. The operation of the preparation method is simple, the cost is largely reduced, the synthesis period of vanadium dioxide (M) is effectively shortened, and the preparation method can be applied to large-scale industrial production.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

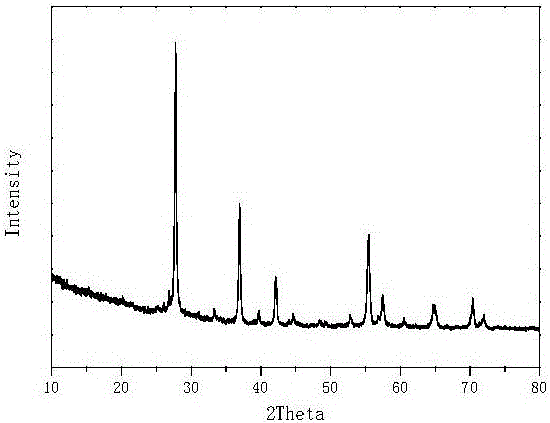

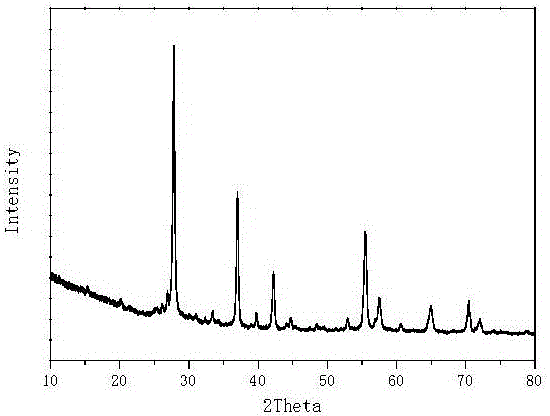

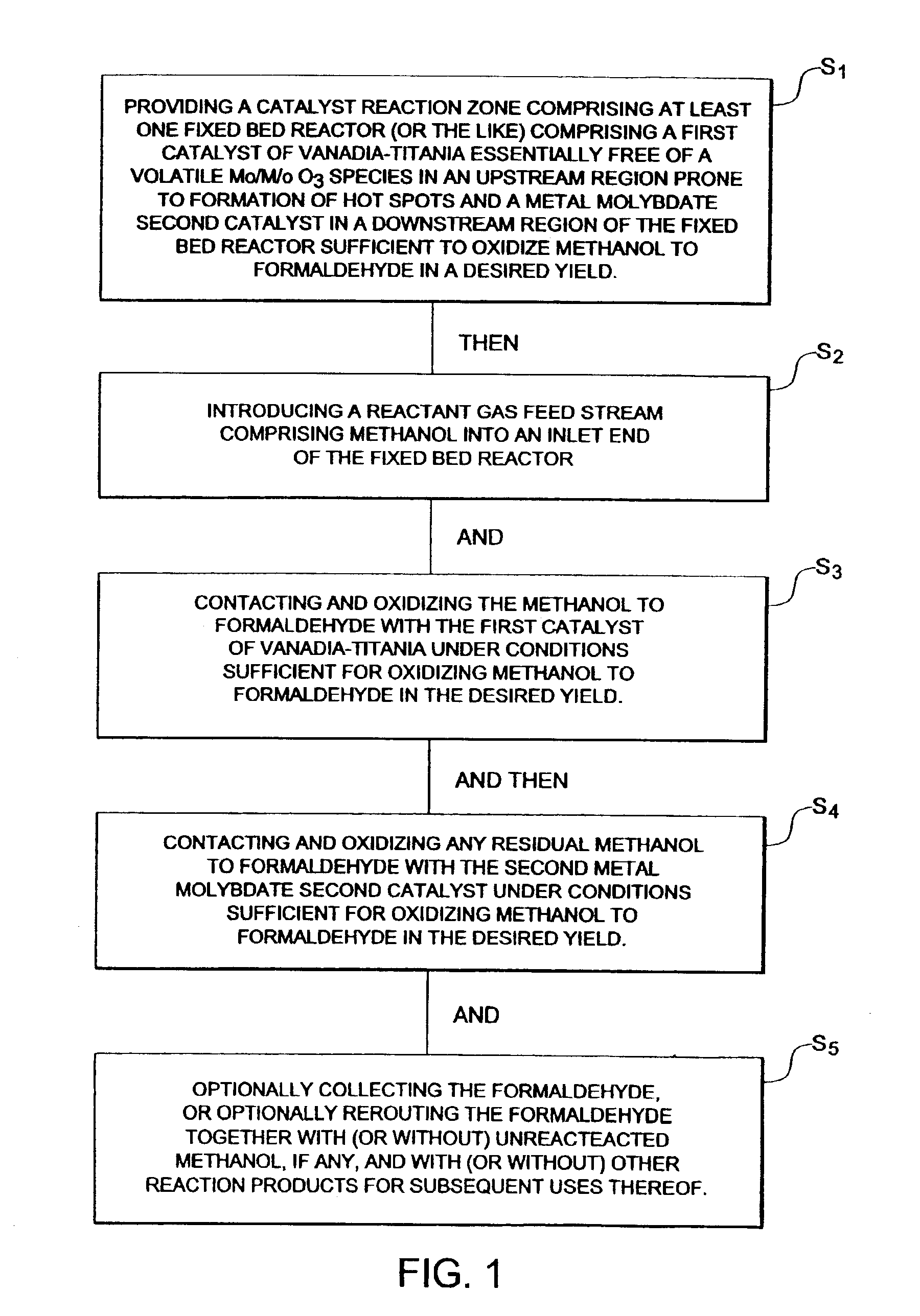

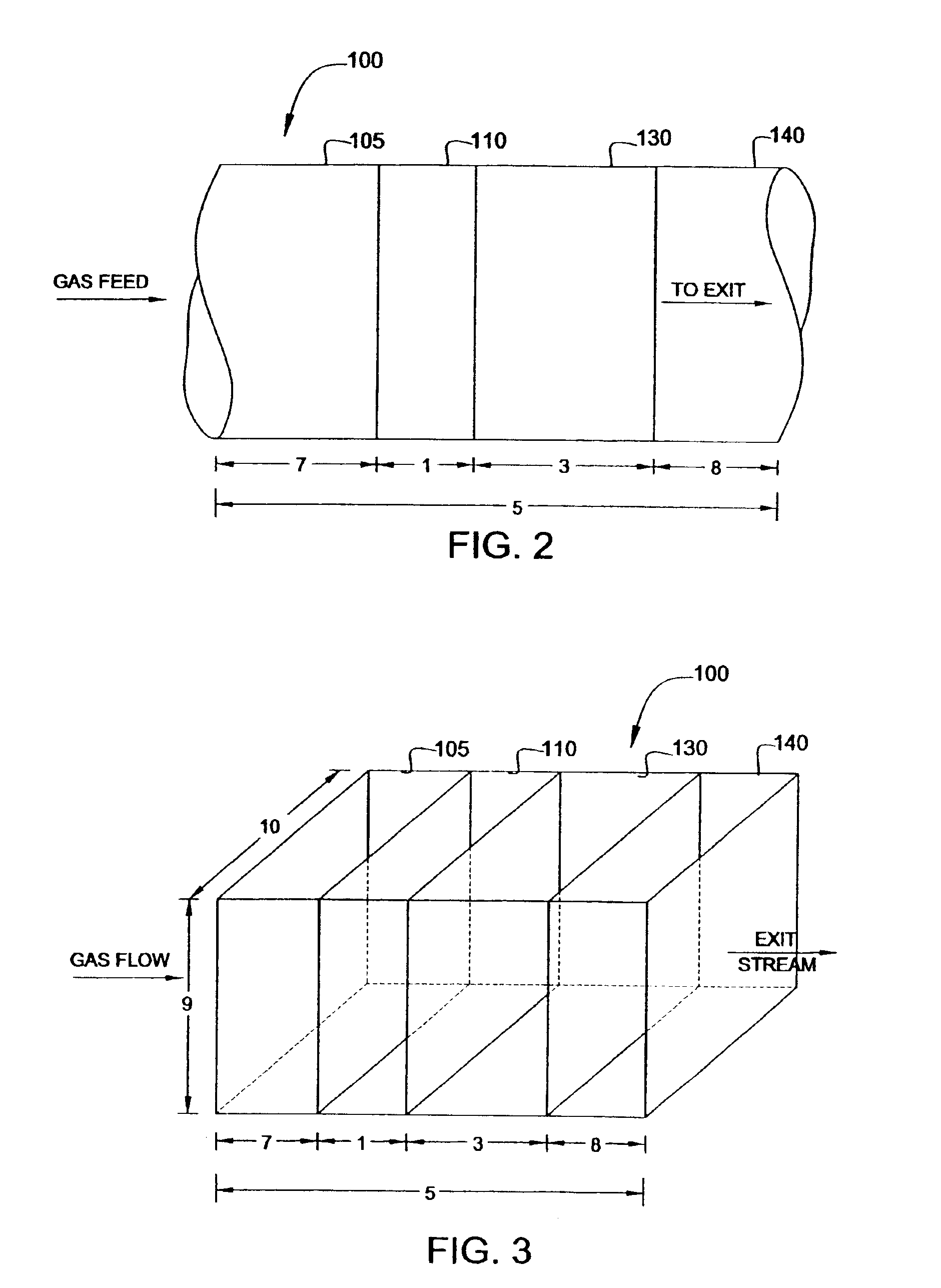

Vanadia-titania metal molybdate dual catalyst bed system and process using the same for methanol oxidation to formaldehyde

InactiveUS6930072B2High selectivitySpeed up the conversion processOrganic compound preparationCarbonyl compound preparationMolybdateFixed bed

A process and a catalyst reaction zone comprising one or more fixed bed reactors for oxidizing methanol in a reactant gas feed stream to formaldehyde. According to one embodiment, the process comprises introducing the reactant gas feed stream into an upstream region containing a vanadia-titania first catalyst (substantially free of a volatile MoO3 species) under oxidizing conditions to form a partially oxidized reactant gas feed stream which is then introduced under oxidizing conditions into a downstream region containing a metal molybdate second catalyst to further oxidize any residual methanol contained therein. According to another embodiment, a fixed bed reactor comprising an upstream region and a downstream region containing the aforementioned vanadia-titania and metal molybdate catalysts, respectively, is utilized to implement the inventive process to yield a product gas stream containing formaldehyde preferably at a conversion of 85% or more and a selectivity of 90% or more.

Owner:GEORGIA PACIFIC CHEM LLC

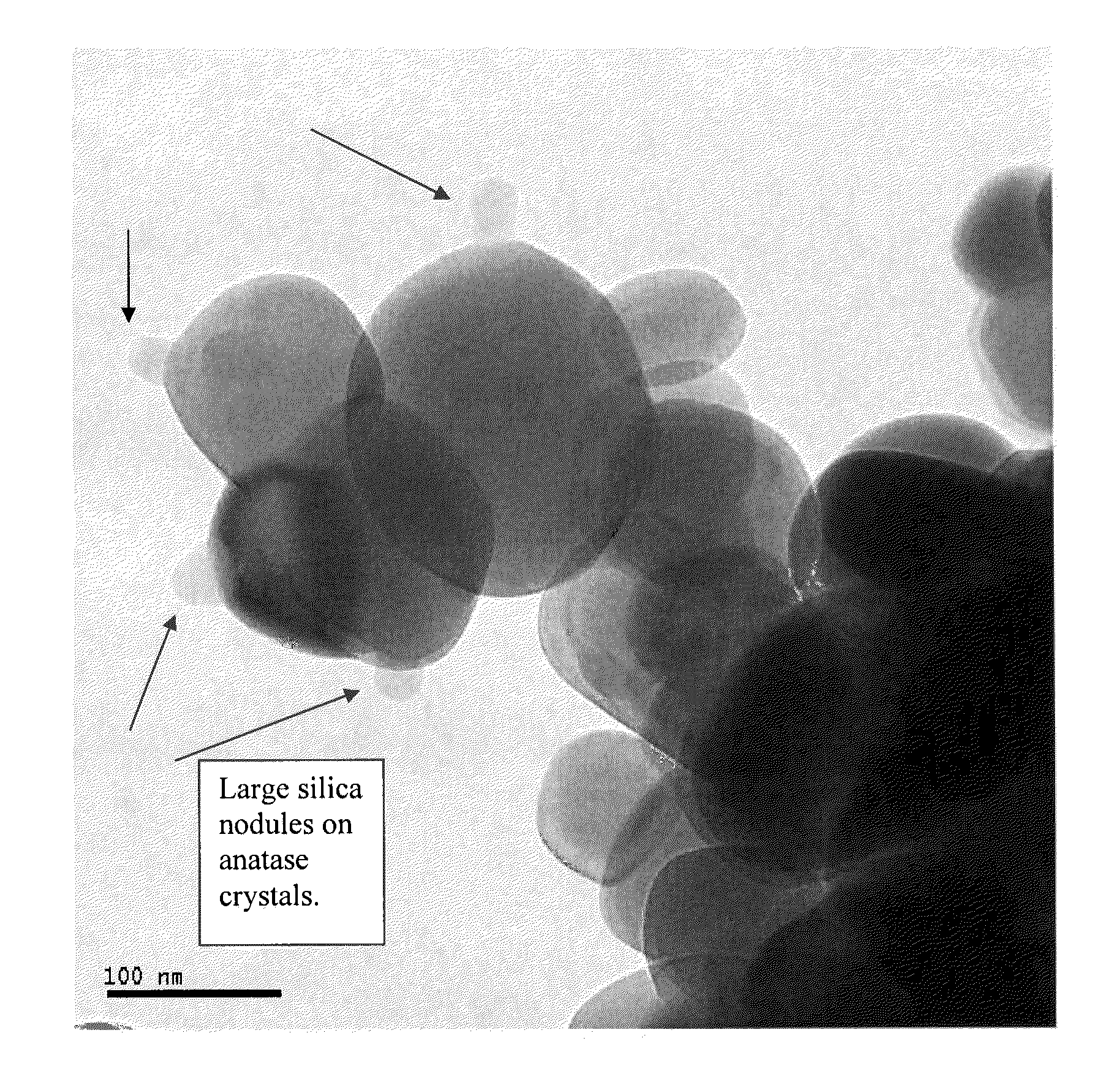

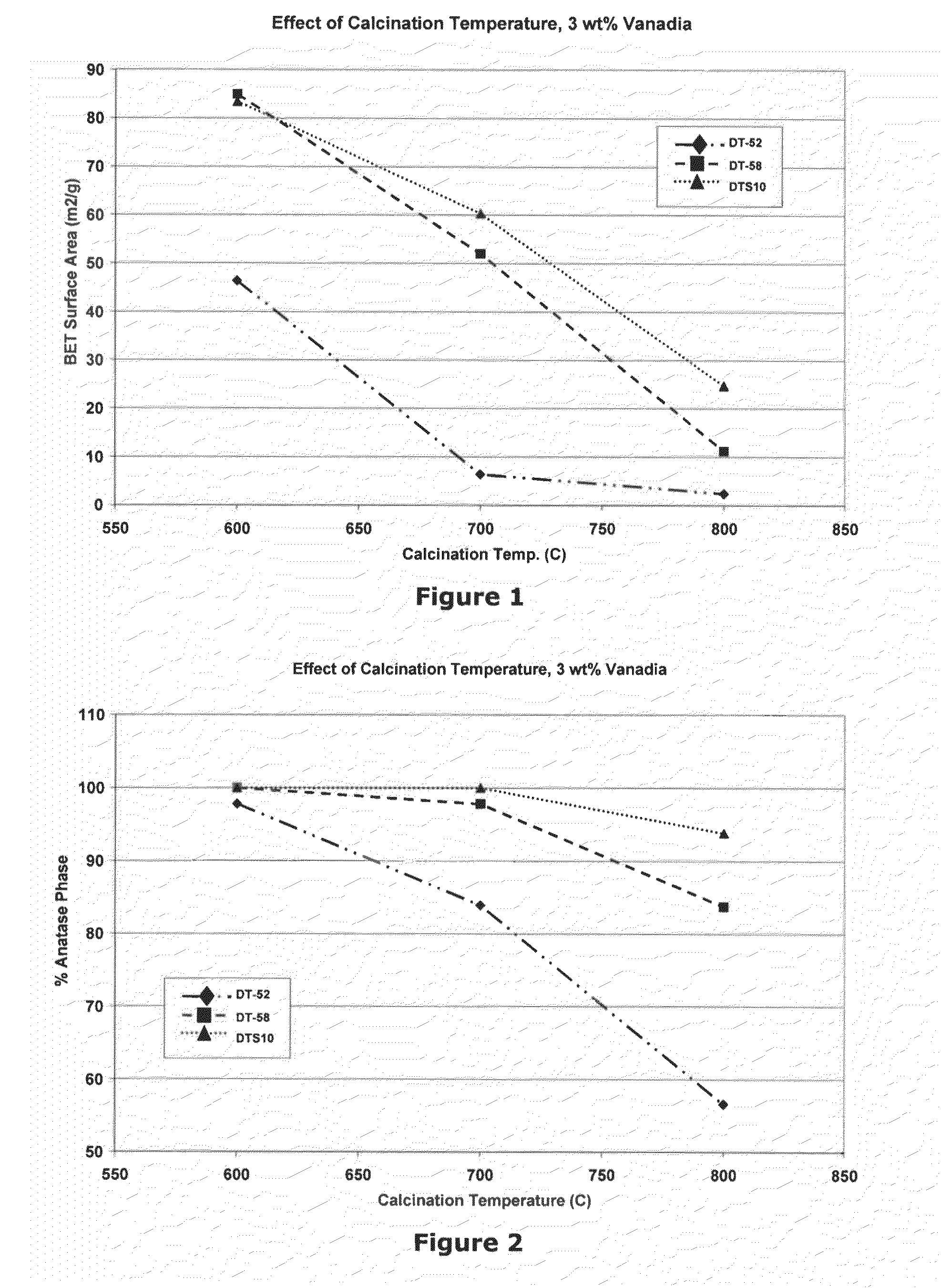

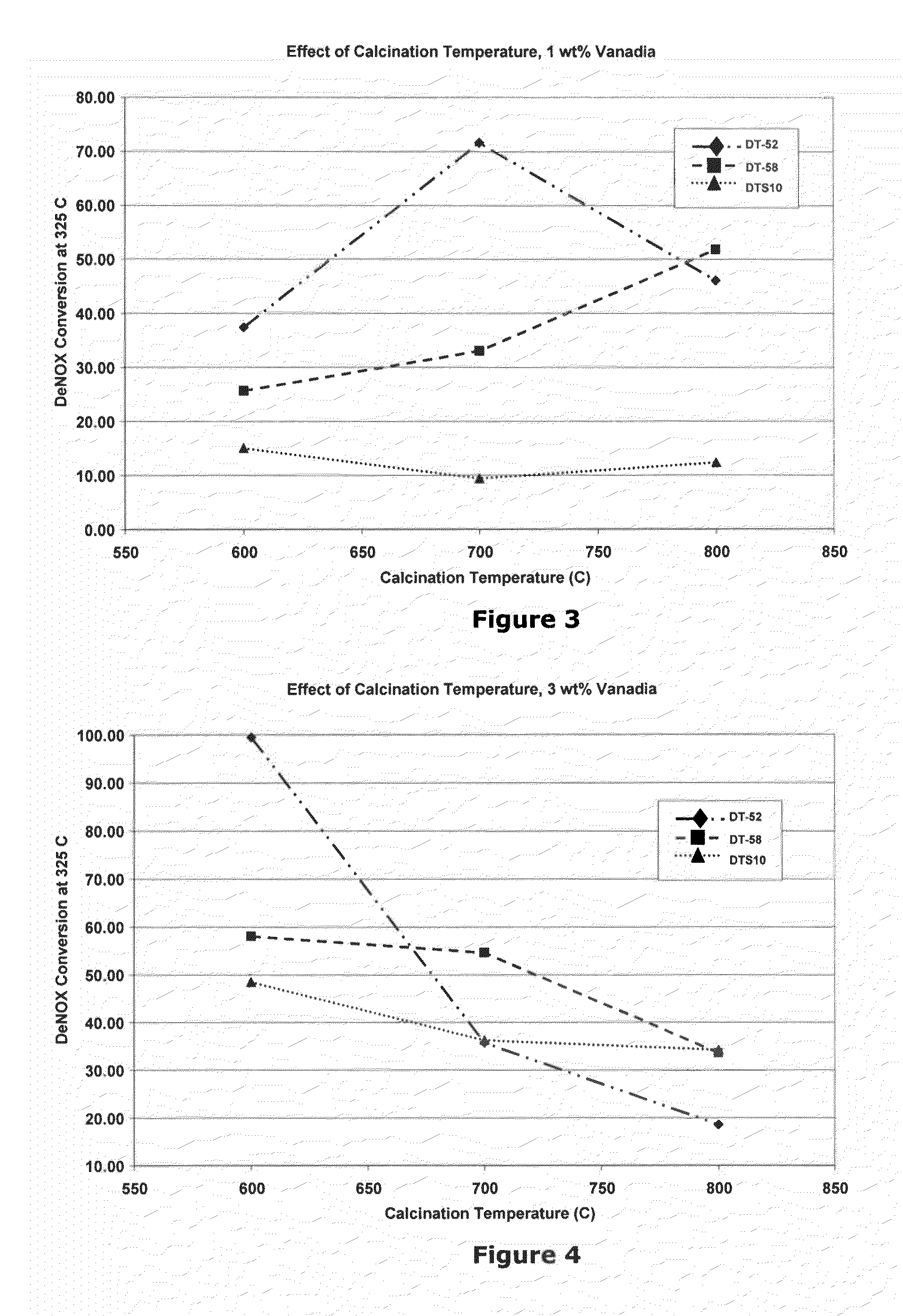

Silica-stabilized ultrafine anatase titania, vanadia catalysts, and methods of production thereof

ActiveUS8545796B2Effective maintenanceEqual and improved catalytic activityGas treatmentSilicaPtru catalystSilicic acid

The invention is directed to compositions and processes for the production of silica-stabilized ultrafine anatase titanias and which may further comprise tungsten and vanadia. The surface stabilization may be by treatment of the TiO2 particles with a low molecular weight and / or small nanoparticle form of silica such as, in preferred embodiments, a tetra(alkyl)ammonium silicate or silicic acid, which serves to efficiently maintain the anatase phase and prevent crystal growth under severe thermal and hydrothermal conditions, even in the presence of vanadia. The vanadia catalysts produced from the novel titanias have equal or improved catalytic activity for selective catalytic reduction of NOx compared to conventional vanadia supported silica-titania based catalysts. The invention is further directed to diesel emission catalytic devices comprising the novel titania-based catalyst compositions.

Owner:TRONOX LLC

Coke oven flue gas denitration catalyst and preparation method thereof

ActiveCN106984349ALower surface energyGood dispersionPhysical/chemical process catalystsDispersed particle separationWater bathsPhosphate

The invention discloses a coke oven flue gas denitration catalyst and a preparation method thereof. The preparation method utilizes ammonium metavanadate as an active precursor, chromium nitrate as an auxiliary agent and oxalic acid and hydrochloric acid as reducing agents, and utilizes phosphoric acid to adjust and control the surface acidity of an active component. The preparation method comprises stirring, water bath heating, drying, calcining to obtain a Cr-doped oxyvanadium phosphate active component, adding the Cr-doped oxyvanadium phosphate active component and anatase TiO2 as a carrier with a specific surface area of greater than or equal to 250 m<2> / g into distilled water according to a ratio, carrying out stirring mixing, and carrying out water bath drying and calcining to obtain the catalyst. The catalyst utilizes phosphoric acid to adjust and control the surface acidity of the catalyst, and utilizes aid chromic nitrate to form an intercalation structure and promote formation of adjacent V<5+> and V<4+>. The catalyst has good low temperature denitration activity and strong SO2 and steam poisoning resistance and is suitable for industrial coke oven flue gas denitrification.

Owner:马鞍山方信环保科技有限公司

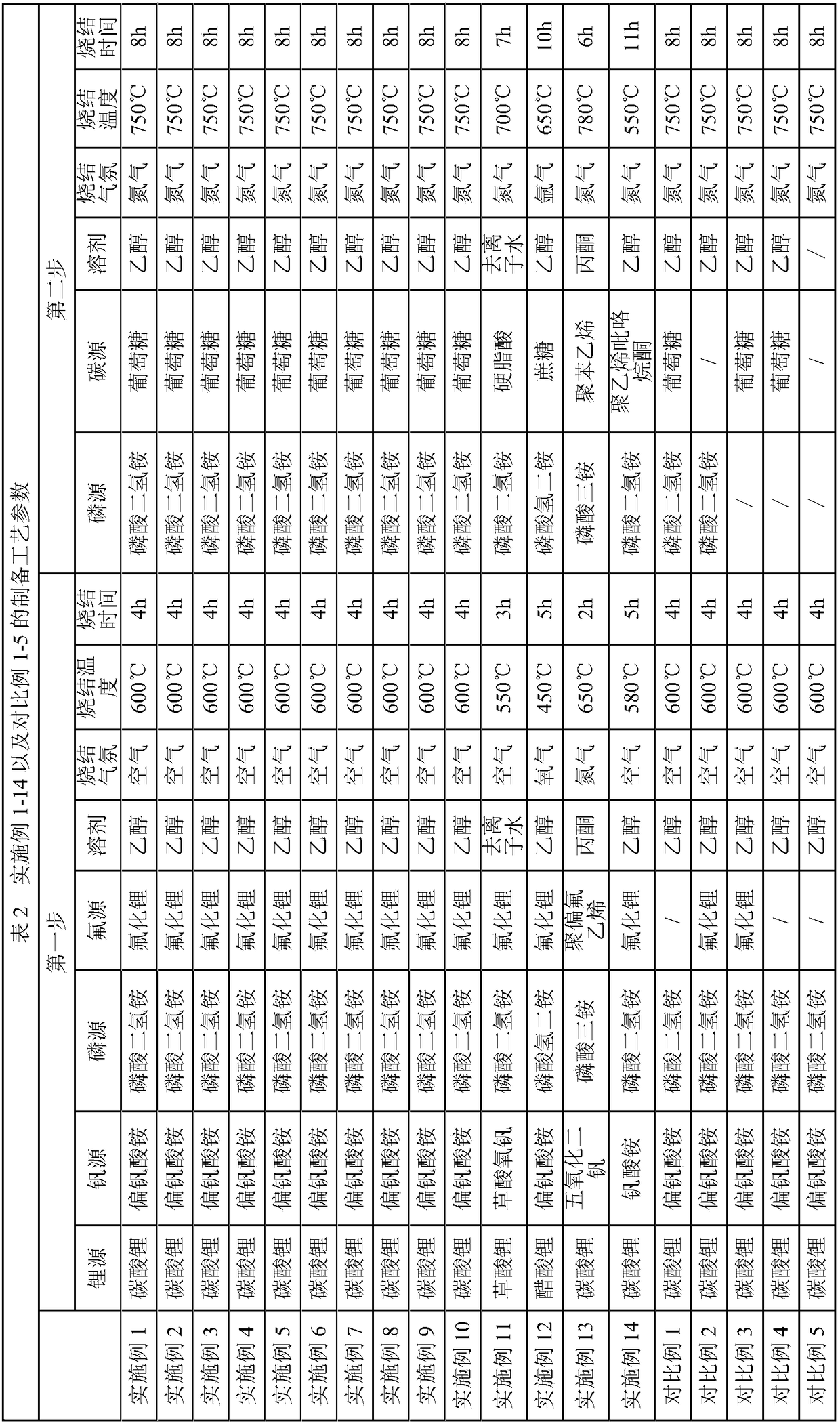

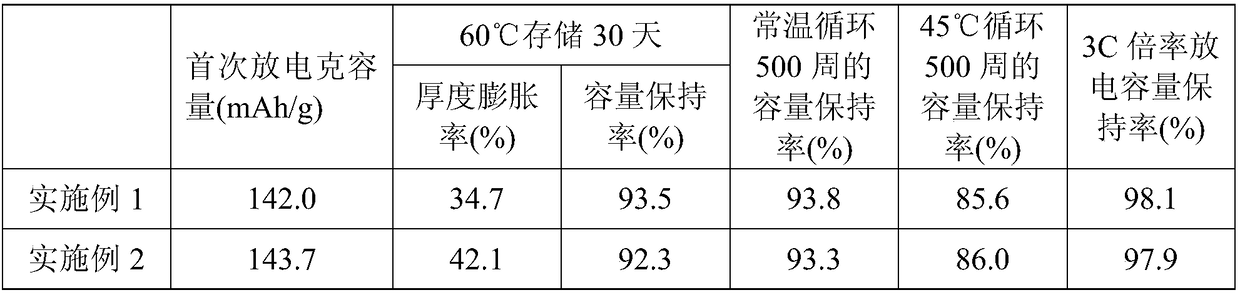

Cathode material, preparation method of same, and lithium secondary battery

ActiveCN109301174AImprove dynamic performanceImprove electrochemical performanceCell electrodesLi-accumulatorsLithium vanadium phosphate batteryPhosphate

The invention provides a cathode material, a preparation method of same, and a lithium secondary battery. The cathode material has a core-shell structure and includes, successively from interior to exterior, a fluorine-doped lithium oxyvanadium phosphate core layer, a medium transition layer containing lithium pyrophosphate; and a carbon surface coating layer. The cathode material is high in lithium ion diffusion rate and electron conductivity, so that the lithium secondary battery with the cathode material has high first-discharge gram volume, excellent storage performance, cycle performanceand rate performance.

Owner:CONTEMPORARY AMPEREX TECH CO

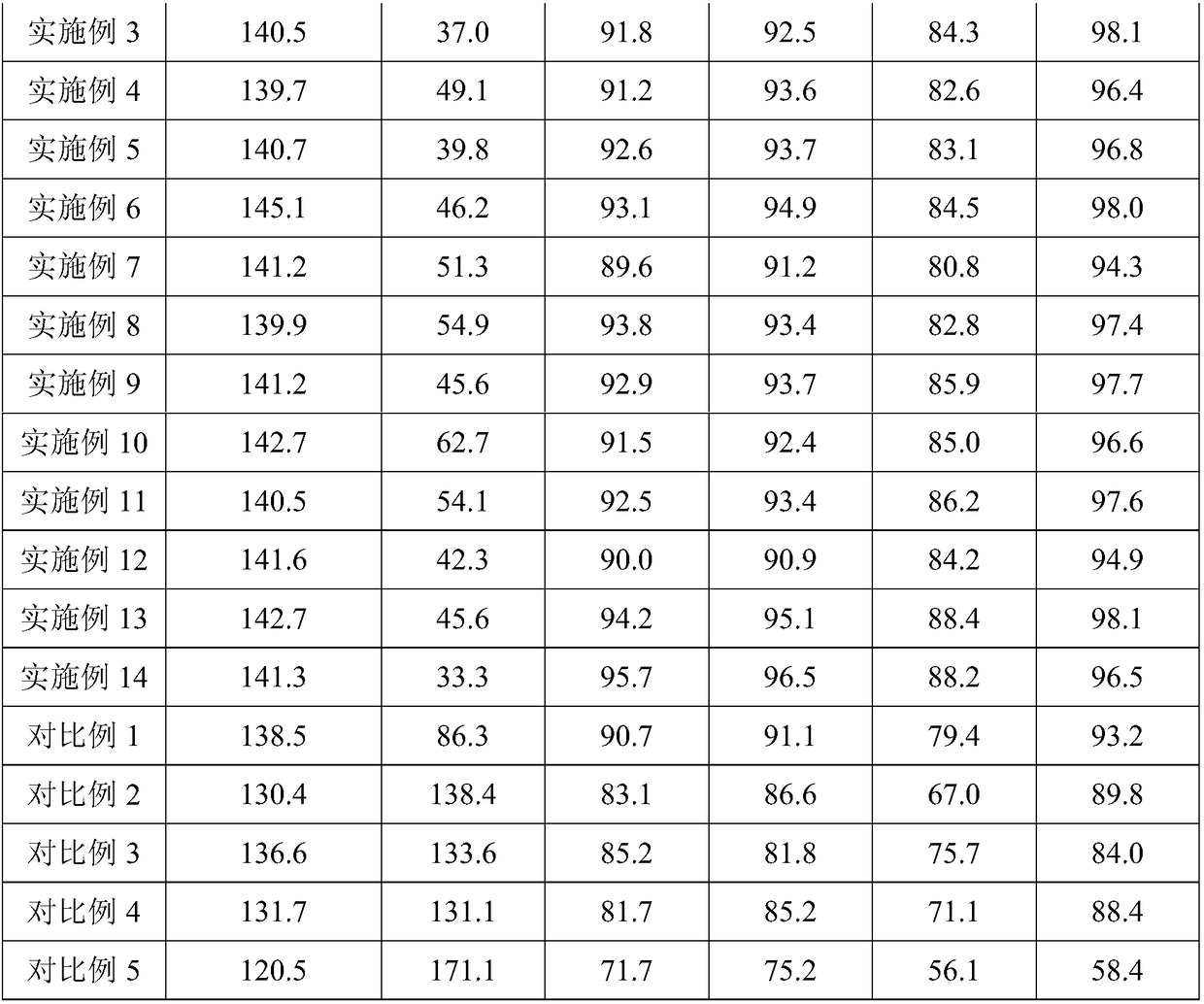

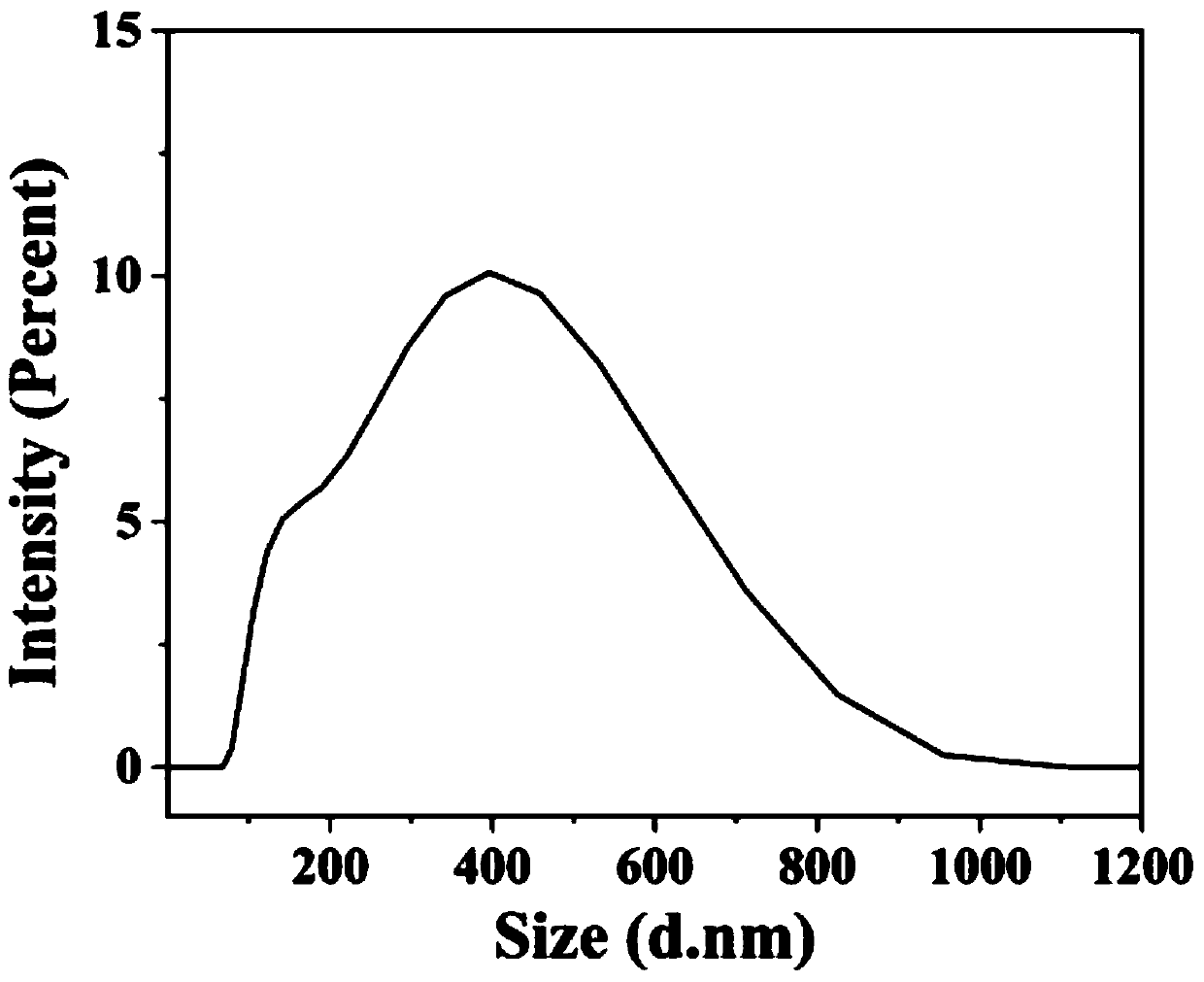

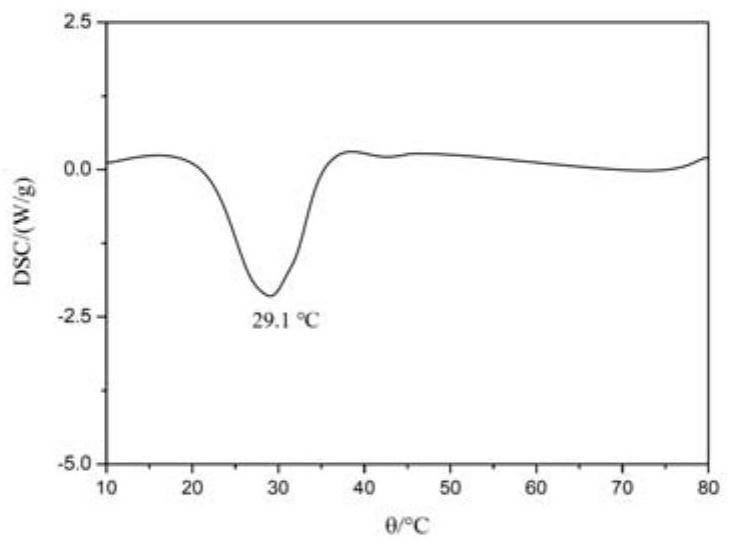

Preparation method of vanadium dioxide organic composite microcapsule

InactiveCN110898773AHigh encapsulation efficiencyImprove stabilityMicroballoon preparationMicrocapsule preparationVanadium dioxideWeather resistance

Belonging to the technical field of synthesis of nano polymer composite materials, the invention provides a vanadium dioxide organic composite microcapsule and a preparation method thereof. The preparation method includes the steps of: (1) preparing an internal water phase, (2) preparing an oil phase, (3) adding the inner water phase prepared in step (1) into the oil phase prepared in step (2) dropwise, and conducting stirring and shearing treatment to obtain a water-in-oil type primary emulsion, (4) preparing an external water phase, and (5) dropwise adding the water-in-oil type primary emulsion prepared in step (3) into the external water phase prepared in step (4), performing stirring at 20-100DEG C, and carrying out aftertreatment to obtain the vanadium dioxide organic composite microcapsule. The preparation method of the vanadium dioxide organic composite microcapsule provided by the invention is simple to operate, and the prepared vanadium dioxide organic composite microcapsule has high encapsulation efficiency and enhanced weather resistance, so that the dispersity of vanadium dioxide in paint is improved, and the industrial application range of vanadium dioxide nanopowder is widened.

Owner:UNIV OF JINAN +2

Degradable environment-friendly packaging bag material and preparation method thereof

InactiveCN110746675AImprove antibacterial propertiesImprove tensile propertiesFlexible coversWrappersLow-density polyethyleneMethacrylate

The invention discloses a degradable environment-friendly packaging bag material and a preparation method thereof, and belongs to the technical field of logistics packaging, wherein the material comprises the following raw materials: low-density polyethylene, an MBS resin, butyl stearate, a butadiene styrene rubber, calcium carbonate, bamboo powder, nanometer copper oxide powder, zinc powder, zirconium oxide powder, zinc ethylhexanoate, microcrystalline paraffin, ramie fiber, vanadium oxide fiber, 2-hydroxyethyl-2-hydroxypropyl methyl ether cellulose, gamma-(2,3-epoxypropoxy)propyltrimethoxysilane, polylactic acid, sodium dioctylsulfosuccinate and 2-(dimethylamino)ethyl-2(alcohol) 2-methacrylate, and is prepared through raw material mixing, mixing, melt extrusion and other steps. Accordingto the invention, the prepared packaging bag material has advantages of excellent antibacterial property, excellent tensile property, excellent degradation property, excellent environmental protection property and the like, the production cost can be reduced, and the application requirements in the technical field of logistics packaging are met.

Owner:温州丰宝客科技有限公司

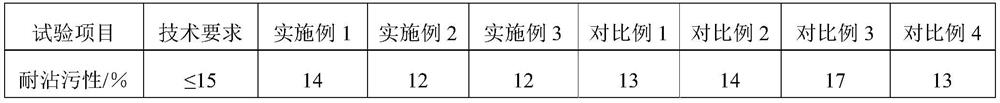

Preparation method of vanadium dioxide-zinc sulfide core-shell structure nano material and heat insulation coating

InactiveCN112239605AExcellent intelligent temperature control performanceHigh hardnessAntifouling/underwater paintsAlkali metal silicate coatingsVanadium dioxideThermal insulation

The invention relates to a preparation method of a vanadium dioxide-zinc sulfide core-shell structure nano material and a thermal insulation coating, and the preparation method of the vanadium dioxide-zinc sulfide core-shell structure nano material comprises the following steps: dispersing a vanadium dioxide nano material in water to prepare a suspension; mixing the suspension with mercapto-alkylacid to prepare modified nano particles; and mixing the modified nano particles, a surfactant, water, a zinc source and a sulfur source, carrying out a reaction, carrying out solid-liquid separation after the reaction is completed, collecting the solid, and drying to prepare the vanadium dioxide-zinc sulfide core-shell structure nano material. The vanadium dioxide-zinc sulfide core-shell structurenano material obtained by the preparation method has high stability and dispersibility, and can effectively improve the intelligent temperature regulation and control effect of the heat insulation coating.

Owner:ASIA PAINT SHANGHAI

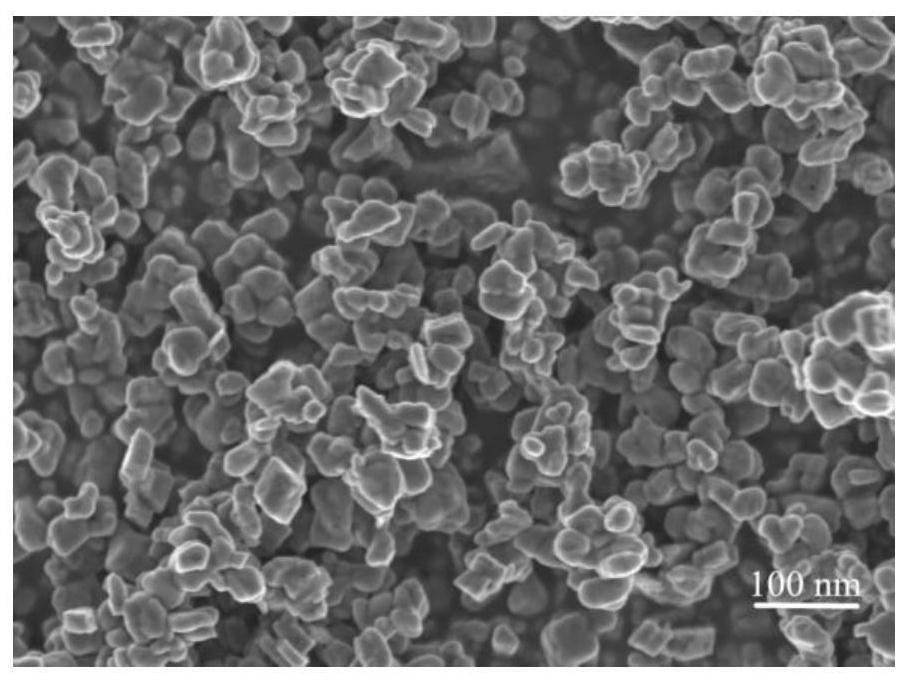

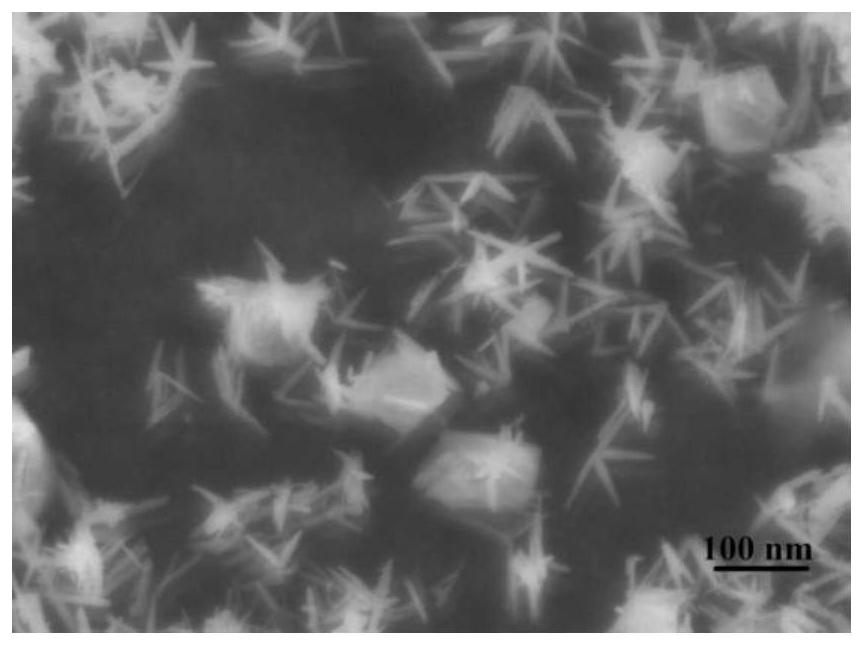

Method for preparing nano vanadium dioxide by taking pentavalent vanadium alkoxide as raw material

InactiveCN112125337AHigh particle size crystallinitySmall granularityNanotechnologyVanadium oxidesVanadium dioxideOrganosolv

The invention belongs to the technical field of preparation of vanadium dioxide, and particularly relates to a method for preparing nano vanadium dioxide by taking pentavalent vanadium alkoxide as a raw material. Aiming at the problem that the particle size of vanadium dioxide prepared by the existing solvothermal method is still too large, the invention provides the method for preparing nano vanadium dioxide by taking pentavalent vanadium alkoxide as the raw material. The method comprises the following steps: uniformly mixing an organic solvent, pentavalent vanadium alkoxide, a morphology regulating agent and an organic reducing agent in a mass ratio of 70: (0.2-1): (0.1-1): (2-10) to form a uniform solution; and putting the solution into a reaction kettle with a polytetrafluoroethylene lining, reacting at 120-180 DEG C for 2-24 hours, and centrifuging, washing and drying the product after the reaction is finished, thereby obtaining the nano vanadium dioxide powder. The prepared vanadium dioxide powder can be synthesized in one step, the technological method is simple, low in cost and easy to apply and popularize, and the prepared vanadium dioxide is high in particle size crystallinity, good in uniformity, smaller in particle size and suitable for being used as a window film material, and the particle size is about 40-60 nm.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

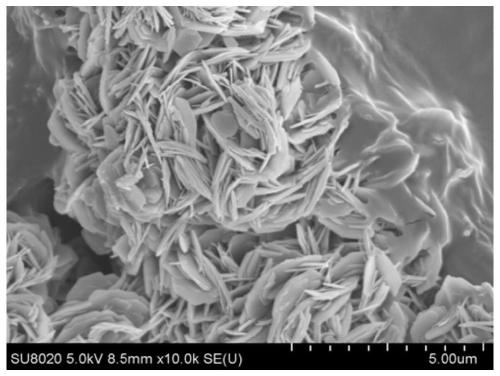

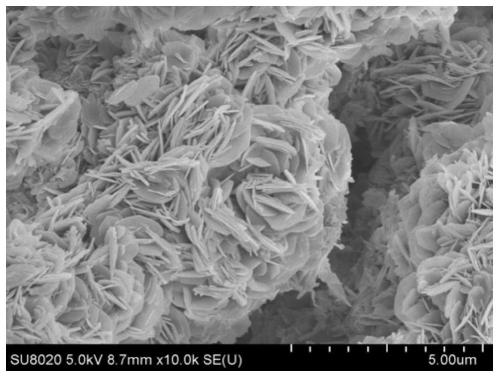

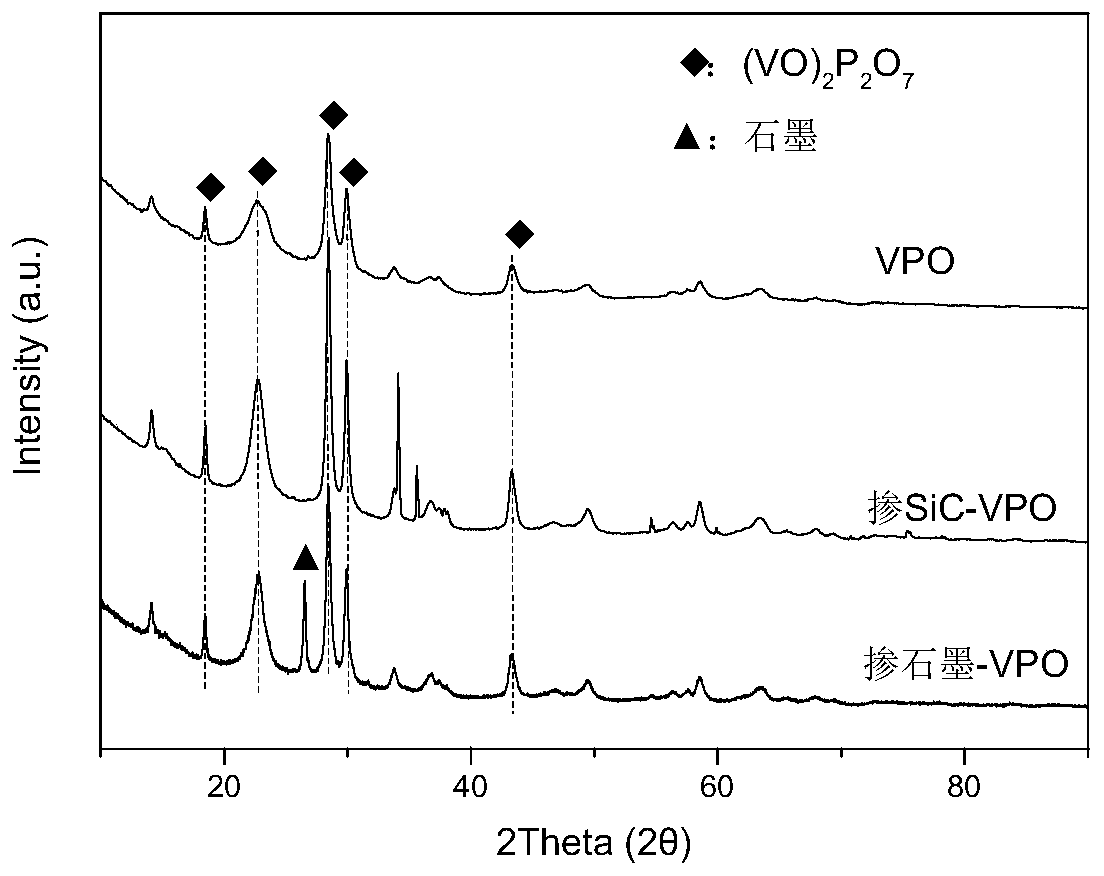

Oxyvanadium phosphate catalyst and preparation method and application thereof

InactiveCN109731594AEvenly heatedUniform and stable heatingOrganic chemistryPhysical/chemical process catalystsAlcoholPhosphate

The invention belongs to the technical field of catalysis and mainly relates to a preparation method of an oxyvanadium phosphate catalyst and application of the oxyvanadium phosphate catalyst in maleic anhydride preparation using selective n-butane oxidation. The preparation method includes the steps of firstly, mixing a vanadium source, benzyl alcohol, C1-C8 monohydric alcohol and a heat-conduction material to obtain a mixture, and performing reaction, wherein the heat-conduction material is at least one of SiC, graphite, graphene and carbon nanotubes; secondly, mixing the reaction product obtained in the first step with a phosphorus source, heating to 100-200 DEG C, and performing reaction to obtain a oxyvanadium phosphate precursor; thirdly, calcining to obtain the oxyvanadium phosphatecatalyst. The preparation method has the advantages that the heat-conduction material is added during the preparation and can effectively achieve heat conduction to solve the problem of local overheat; the uniform and stable formation of active phase is promoted effectively, the catalyst is promoted to be heated evenly during reaction, and catalyst performance is increased.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

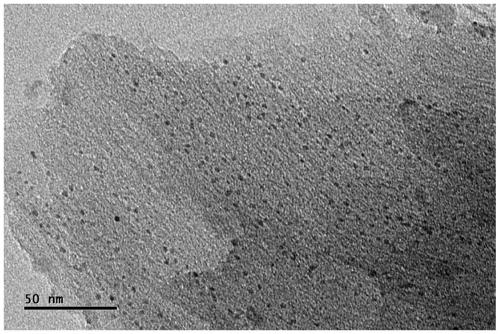

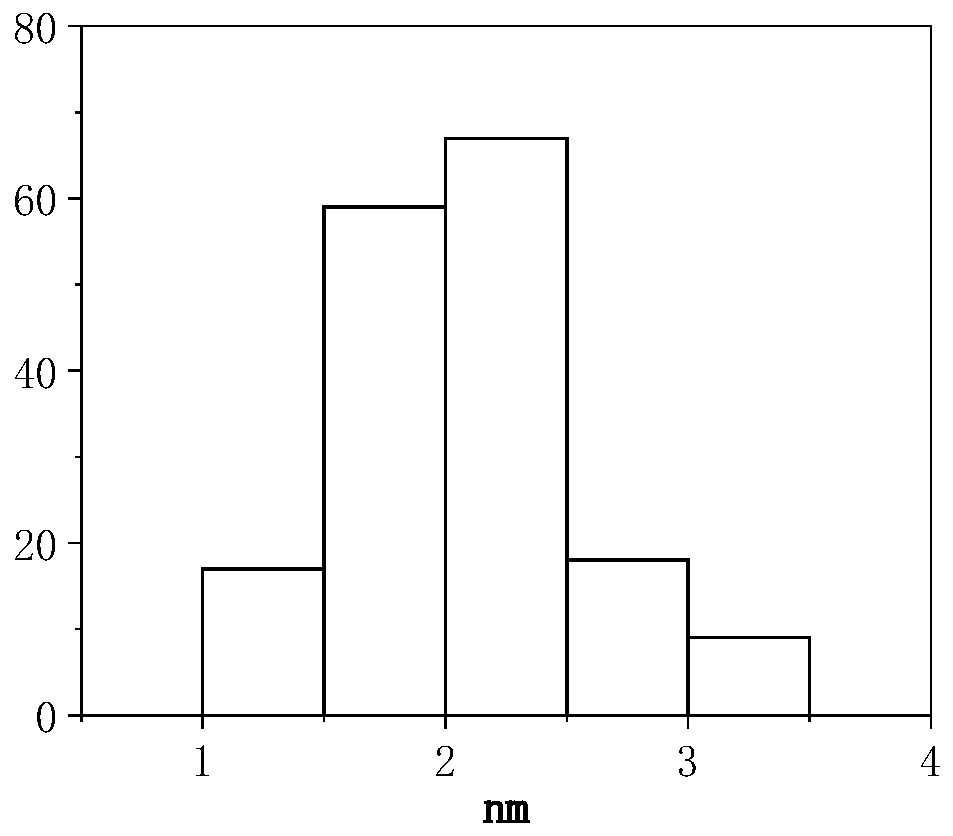

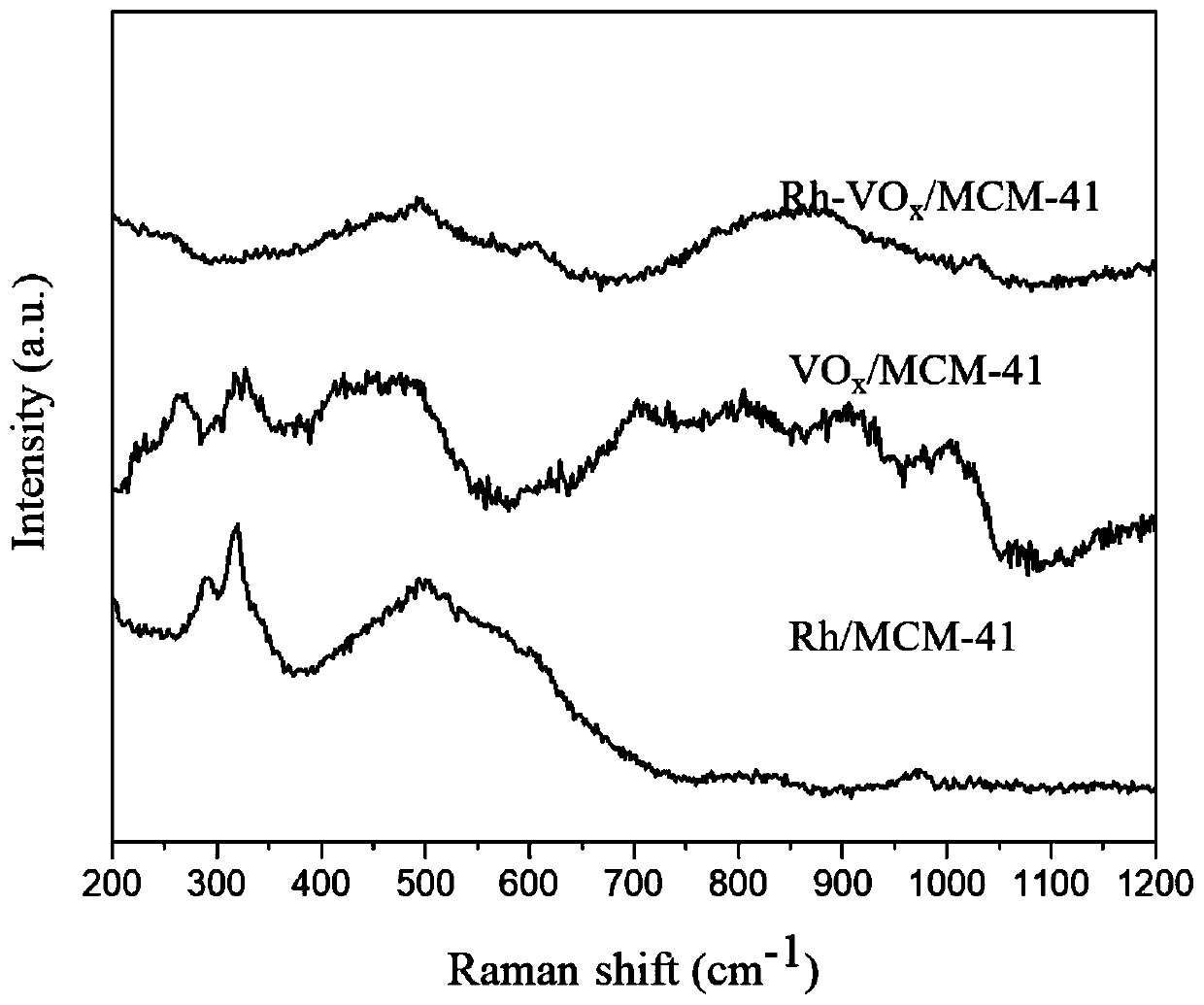

Carrier supported vanadium oxide promoted Rh-based catalyst as well as preparation method and application thereof

ActiveCN111434382AHigh yieldImprove conversion rateMolecular sieve catalystsOrganic compound preparationOXALIC ACID DIHYDRATEMolecular sieve

The invention discloses a carrier supported vanadium oxide promoted Rh-based catalyst and a preparation method and application thereof. A molecular sieve is used as a carrier, and is loaded with an active component Rh, V is used as assistants, and the mass percentage of Rh is shown in the specification. When the catalyst is prepared, a co-impregnation method is adopted, the carrier is immersed inan oxalic acid aqueous solution of rhodium chloride and ammonium metavanadate, drying and roasting are performed, and the catalyst is obtained. The catalyst is suitable for a reaction for preparing ethanol by hydrogenating carbon dioxide and carbon monoxide; the Rh is used as an active component, compared with a traditional Rh catalyst, the catalyst has the characteristics of high ethanol selectivity and low operation pressure, and compared with Rh catalysts promoted by other assistants, the catalyst adopts the V as an assistant, so that the catalyst activity and the ethanol selectivity are greatly improved, and meanwhile, long-time stability is also maintained.

Owner:TIANJIN UNIV

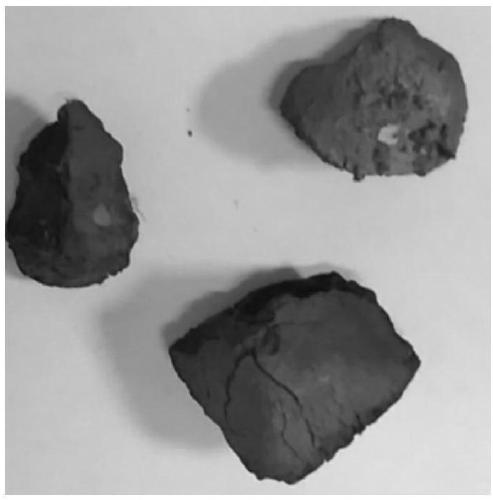

Method for treating oxidized vanadium-nitrogen alloy

The invention relates to a method for treating an oxidized vanadium-nitrogen alloy and belongs to the technical field of vanadium-nitrogen alloys. The method actually comprises the steps that (1), a reducing agent, water and a binder are mixed in a ratio of 1 : (0.5-1) : 0.01, still placement is performed after uniform stirring is performed, and a mixed material slurry is obtained; (2), the vanadium-nitrogen alloy with the surface being discolored by oxidation is put in the mixed material slurry, sufficient stirring is performed to make the mixed material slurry be in sufficient contact with the vanadium-nitrogen alloy surface, and the vanadium-nitrogen alloy is taken out and redundant mixed materials on the surface of the vanadium-nitrogen alloy are dried; (3), the dried vanadium-nitrogenalloy in the step(2) is kneaded; and (4), the obtained vanadium-nitrogen alloy in the step(3) is dried in the air, the vanadium-nitrogen alloy dried in the air is placed on the upper layer of a vanadium-nitrogen semi-finished ball to be machined, then drying, carbonizing reduction and nitriding sintering are performed on the vanadium-nitrogen alloy in a protective gas atmosphere, and the treatedvanadium-nitrogen alloy is obtained. By means of the method for treating the oxidized vanadium-nitrogen alloy, only oxidized parts are treated, and the discolored vanadium-nitrogen alloy can be effectively restored to the normal color of the vanadium-nitrogen alloy.

Owner:济南鲍德炉料有限公司

Preparation method of oxyvanadium phosphate catalyst and application thereof in catalytic oxidation reaction

ActiveCN107983381ALarge specific surface areaIncrease surface areaPhysical/chemical process catalystsOrganic compound preparationPhosphateReaction temperature

The invention discloses a preparation method of an oxyvanadium phosphate catalyst. The preparation method disclosed by the invention comprises the following steps: carrying out material synthesis reaction on phosphorus sources such as sodium hypophosphite and ammonium hypophosphite and one or more vanadium sources in vanadium pentoxide and ammonium metavanadate in multiple kinds of ionic liquid and eutectic mixtures, using assisted microwave heating means in the reaction process, preparing to obtain an oxyvanadium phosphate precursor VOHPO4.1 / 2H2O, and calcining the oxyvanadium phosphate precursor in air containing 1.5% of butane, thereby obtaining the final catalyst oxyvanadium phosphate. The ionic liquid thermosynthesis method adopted in the invention has the advantages of simplicity andconvenience in operation (normal pressure), high specific surface area of the prepared material and the like. Hypophosphite (H2PO<2->, phosphorus of +1 valence state) with high reducing property serves as a reducing agent and a phosphorus source, so that the reaction temperature can be greatly reduced, and the energy consumption is reduced.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Preparation method of nano vanadium dioxide/natural porous carbon electrode material

ActiveCN112233910AImprove performanceLow costMaterial nanotechnologyHybrid capacitor electrodesVanadium dioxidePorous carbon

The invention discloses a preparation method of a nano vanadium dioxide / natural porous carbon electrode material. The method comprises the following steps: a, preprocessing a pure cotton felt; b, carbonizing the pure cotton felt treated in the step a; c, preparing an ethylene glycol vanadyl solution; and d, introducing nano vanadium dioxide: putting the pure cotton felt subjected to carbonizationtreatment into vacuum heating equipment, starting vacuum and heating, continuously introducing nitrogen, and controlling a temperature to be 300-500 DEG C; meanwhile, diluting the ethylene glycol vanadyl solution with ethanol, carrying out ultrasonic atomization, and then feeding into vacuum heating equipment to react with the pure cotton felt; and after the reaction is finished, cooling to obtainthe nano vanadium dioxide / natural porous carbon electrode material. According to the method, the pure cotton felt is used as a raw material, the pure cotton felt is subjected to carbonization treatment, ethylene glycol vanadyl is decomposed into vanadium dioxide to be attached to the carbonized pure cotton felt in an ultrasonic atomization and calcination mode, and the obtained electrode materialis excellent in performance, low in cost and environmentally friendly.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

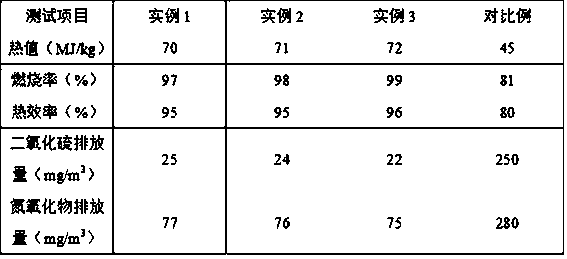

Preparation method for catalytic oxygen-evolving clean fuel

ActiveCN108587702AHigh carbon contentHigh calorific valueLiquid carbonaceous fuelsFuel additivesCellulosePhosphate

The invention discloses a preparation method for a catalytic oxygen-evolving clean fuel, belonging to the technical field of fuel preparation. According to the invention, cellulose in a straw biological raw material is decomposed into C5 sugar and C6 sugar by using Clostridium thermoceUum through a fermentation method, wherein the C5 sugar is converted into furfural under the action of a solid acid catalyst, and the furfural is oxidized into furoic acid under the catalytic effect of green oxyvanadium phosphate powder, so an obtained clean fuel has high calorific value. A plant fuel obtained byusing the preparation method provided by the invention comprises a polymer component namely butanediol polyfurandicarboxylate, and dry ice is added into the preparation process of the plant fuel; inaddition, the C6 sugar in the cellulose is firstly converted into levulinic acid in the process of catalysis, so generation of carbon monoxide is reduced; methanol is used as a main liquid fuel, so the problem of excess production capacity of methanol in China can be alleviated; combustion products are basically free of harmful gases like nitrides and sulfides; micron magnesium powder used in thepreparation method provided by the invention can help combustion and has desulfurization effect to coal powder in a solid fuel; thus, the fuel is cleaner and has broad application prospects.

Owner:江苏兆维塑料科技有限公司

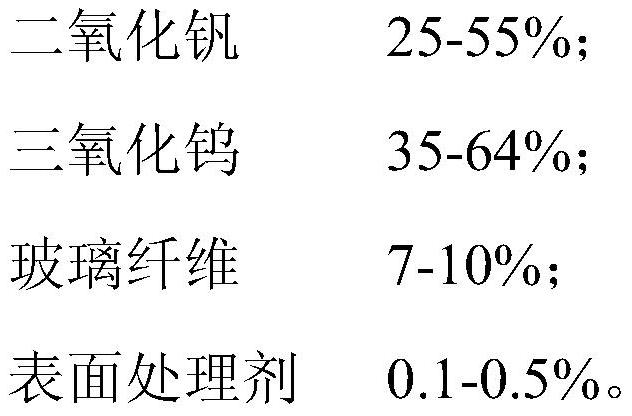

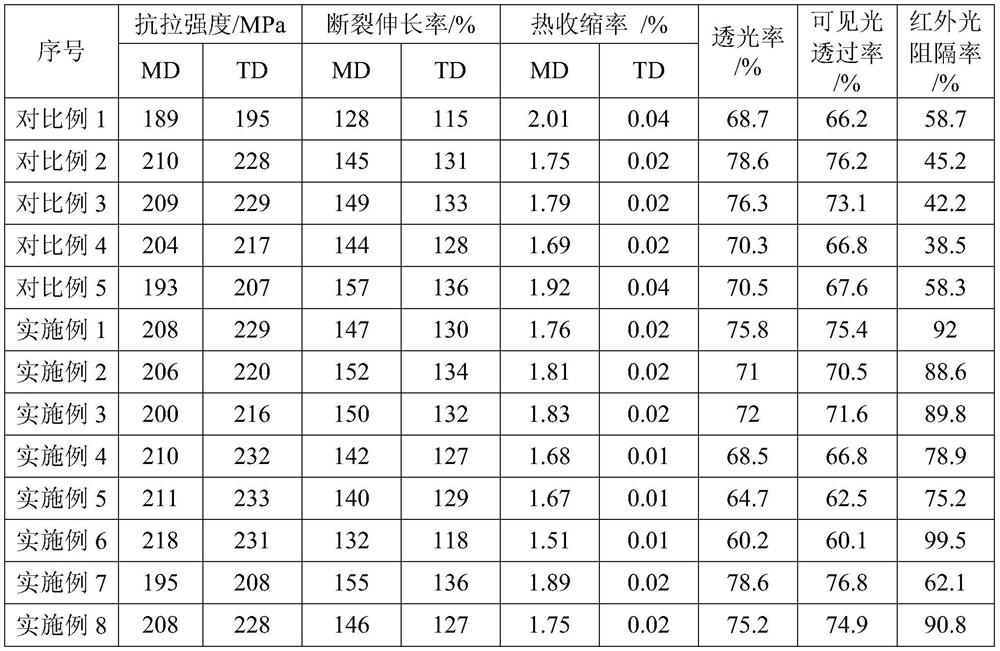

Infrared barrier master batch, infrared barrier polyester film and preparation method of infrared barrier polyester film

The invention relates to the technical field of high polymer materials, and discloses an infrared barrier master batch, an infrared barrier polyester film and a preparation method thereof.The infrared barrier master batch is prepared from, by mass on the basis of 100%, 60-70% of polyester and 30-40% of functional additive; wherein the functional additive is prepared from the following raw material components: 25 to 55 percent of vanadium dioxide, 35 to 64 percent of tungsten trioxide, 7 to 10 percent of glass fiber and 0.1 to 0.5 percent of surface treating agent; according to the preparation method, master batches are obtained through melt blending, then the master batches and polyester are subjected to tape casting to form a film, the infrared blocking polyester film is prepared, and the optical-grade infrared blocking polyester film with high visible light transmittance, high infrared blocking rate, high tensile strength and good size stability is obtained through the synergistic effect of vanadium dioxide, tungsten trioxide, glass fibers and a surface treating agent. The preparation method is simple to operate, easy to control, high in production efficiency and suitable for industrial production.

Owner:ZHEJIANG QIANGMENG IND

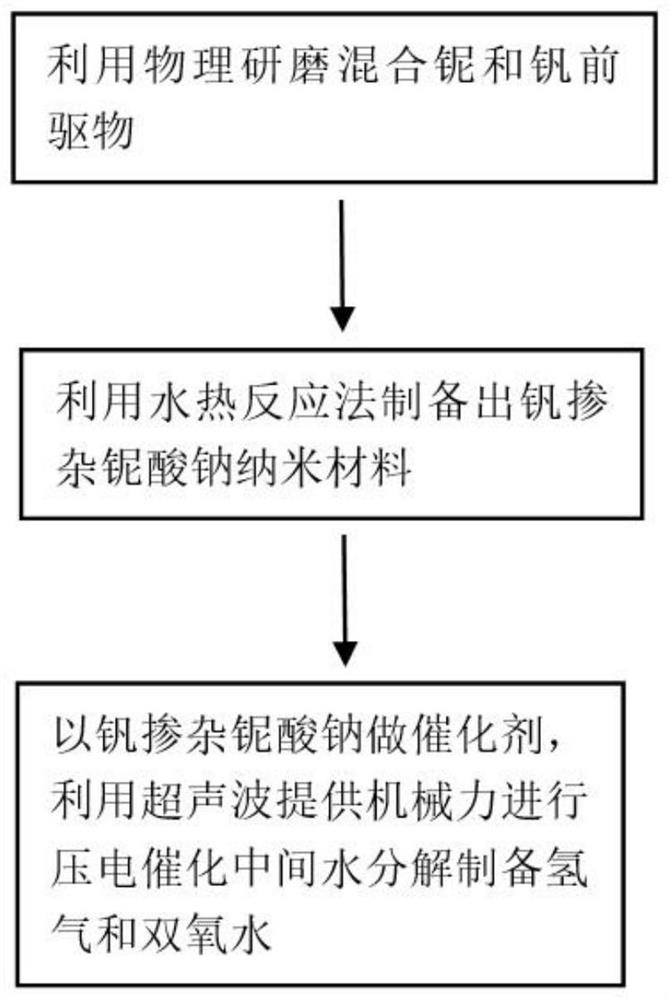

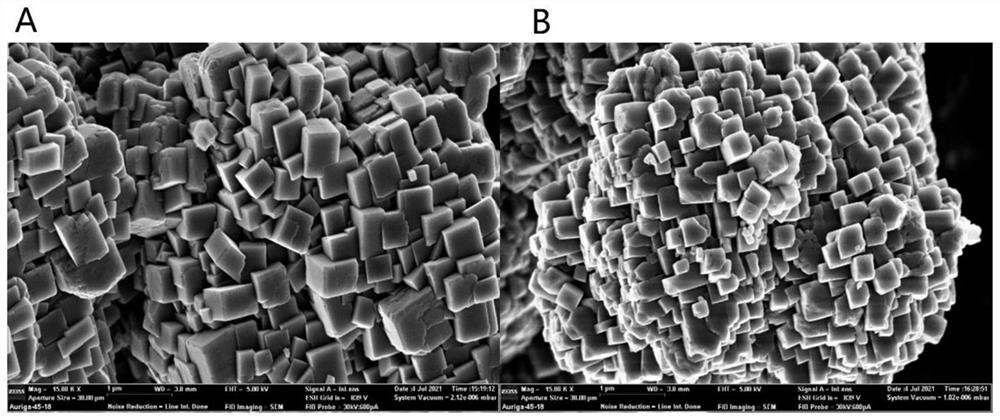

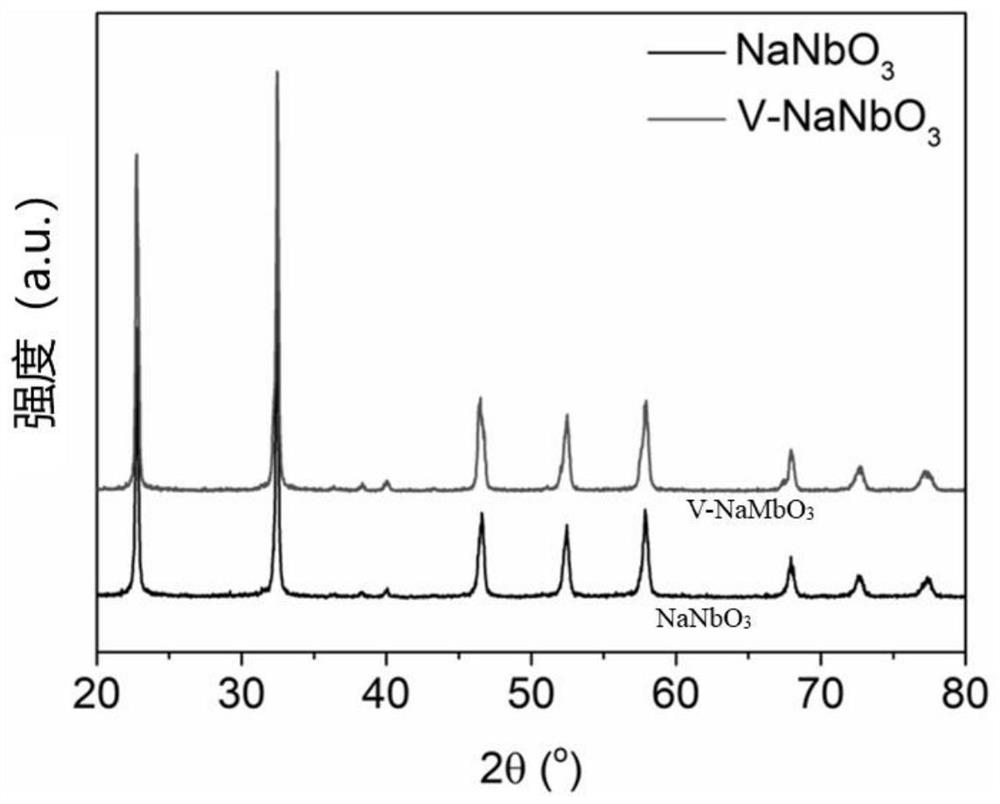

Preparation of vanadium-doped sodium niobate piezoelectric catalyst and application of vanadium-doped sodium niobate piezoelectric catalyst in preparation of hydrogen peroxide and hydrogen by catalytic cracking of intermediate water

PendingCN114588890AImprove efficiencyPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHeterogenous catalyst chemical elementsPtru catalystPhysical chemistry

The invention belongs to the technical field of hydrogen production through water decomposition, and particularly relates to preparation of a vanadium-doped sodium niobate piezoelectric catalyst and application of the vanadium-doped sodium niobate piezoelectric catalyst in preparation of hydrogen peroxide and hydrogen through catalytic cracking of intermediate water. The vanadium-doped sodium niobate piezoelectric catalyst can be applied to preparation of hydrogen peroxide and hydrogen through catalytic cracking of intermediate water, and compared with original sodium niobate, the vanadium-doped sodium niobate piezoelectric catalytic hydrogen production efficiency and the hydrogen peroxide production efficiency are greatly improved, and the vanadium-doped sodium niobate piezoelectric catalytic hydrogen production efficiency and the vanadium-doped sodium niobate piezoelectric catalytic hydrogen production efficiency are greatly improved. And a new way and direction are provided for the method for preparing hydrogen peroxide and hydrogen through catalytic cracking of intermediate water by using the piezoelectric catalyst.

Owner:SUN YAT SEN UNIV

Method for preparing titanium-tungsten co-doped vanadium dioxide powder from vanadium extraction solution

PendingCN113501544ALower phase transition temperatureExcellent optical propertiesVanadium oxidesVanadium dioxideOptical property

The invention discloses a method for preparing titanium-tungsten co-doped vanadium dioxide powder from a vanadium extraction solution, wherein the method comprises the steps: a, adding an acid solution into the vanadium extraction solution, and adjusting the pH value; b, measuring the concentration of vanadium ions in the vanadium extraction solution, and adding a reducing agent; c, adding a tungsten compound and a titanium compound into the solution obtained in the step b, carrying out hydrothermal reaction, and separating to obtain a precipitate; and d, washing and drying the precipitate obtained in the step c to obtain the titanium-tungsten co-doped vanadium dioxide powder. According to the method, the vanadium extraction solution is adopted as the vanadium source, the cost is effectively reduced, the phase change temperature of the vanadium dioxide is reduced through tungsten element doping, meanwhile, the optical property and stability of the vanadium dioxide are improved through titanium element doping, and wide application of the vanadium dioxide in the field of phase change energy saving is promoted.

Owner:ANSTEEL BEIJING RES INST

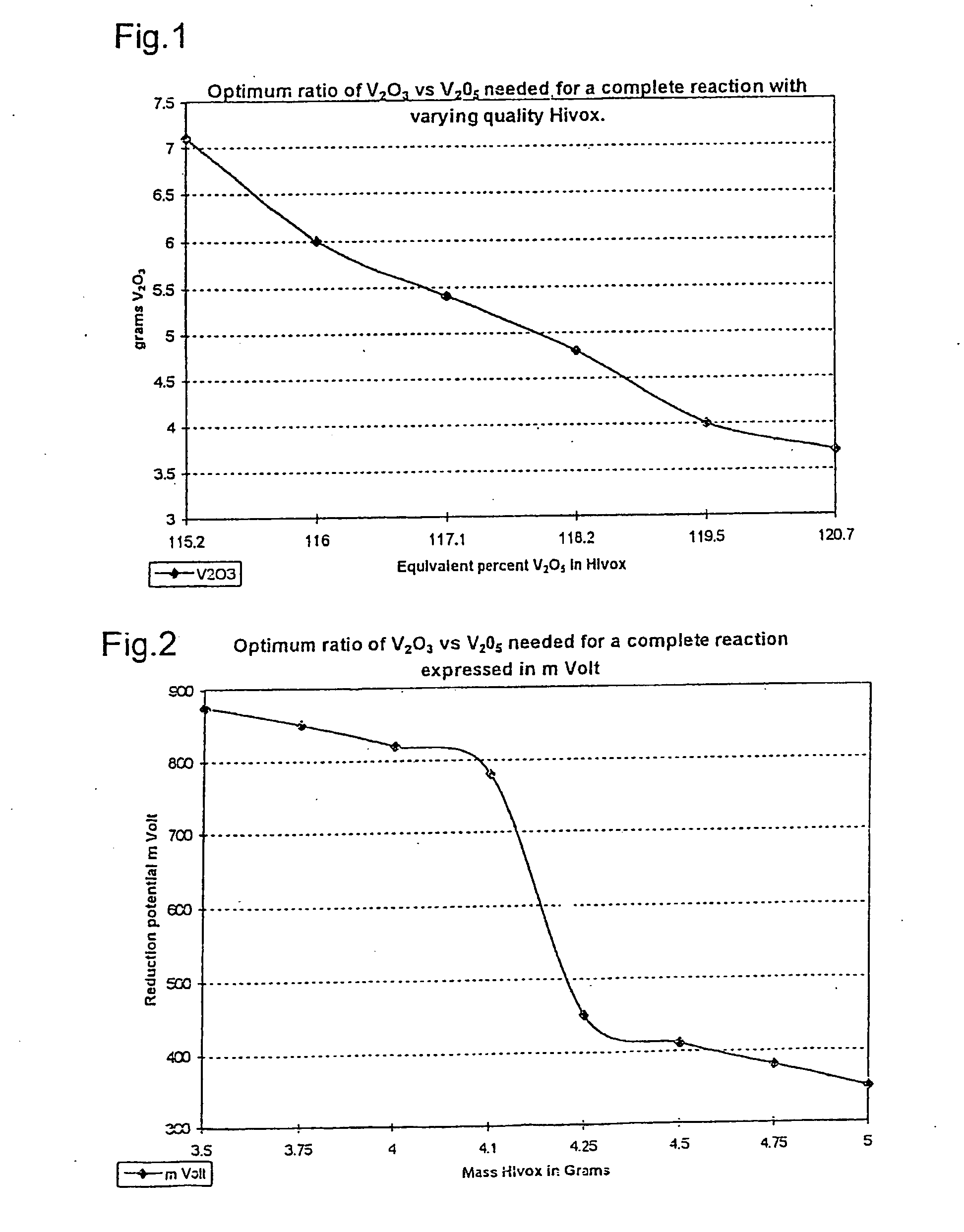

Process for the preparation of vanadyl sulfate solution

A process for producing a vanadyl sulphate solution (VOSO4) comprises forming a suspension of vanadium trioxide (V2O3) in a sulphuric acid solution and contacting the V2O3 suspension with a strong oxidising agent under controlled conditions to produce the VOSO4 solution. A preferred oxidising agent is hydrogen peroxide, which is added very slowly to the V2O3 suspension due to the violent nature of the reaction.

Owner:VANCHEM VANADIUM PROD PTY

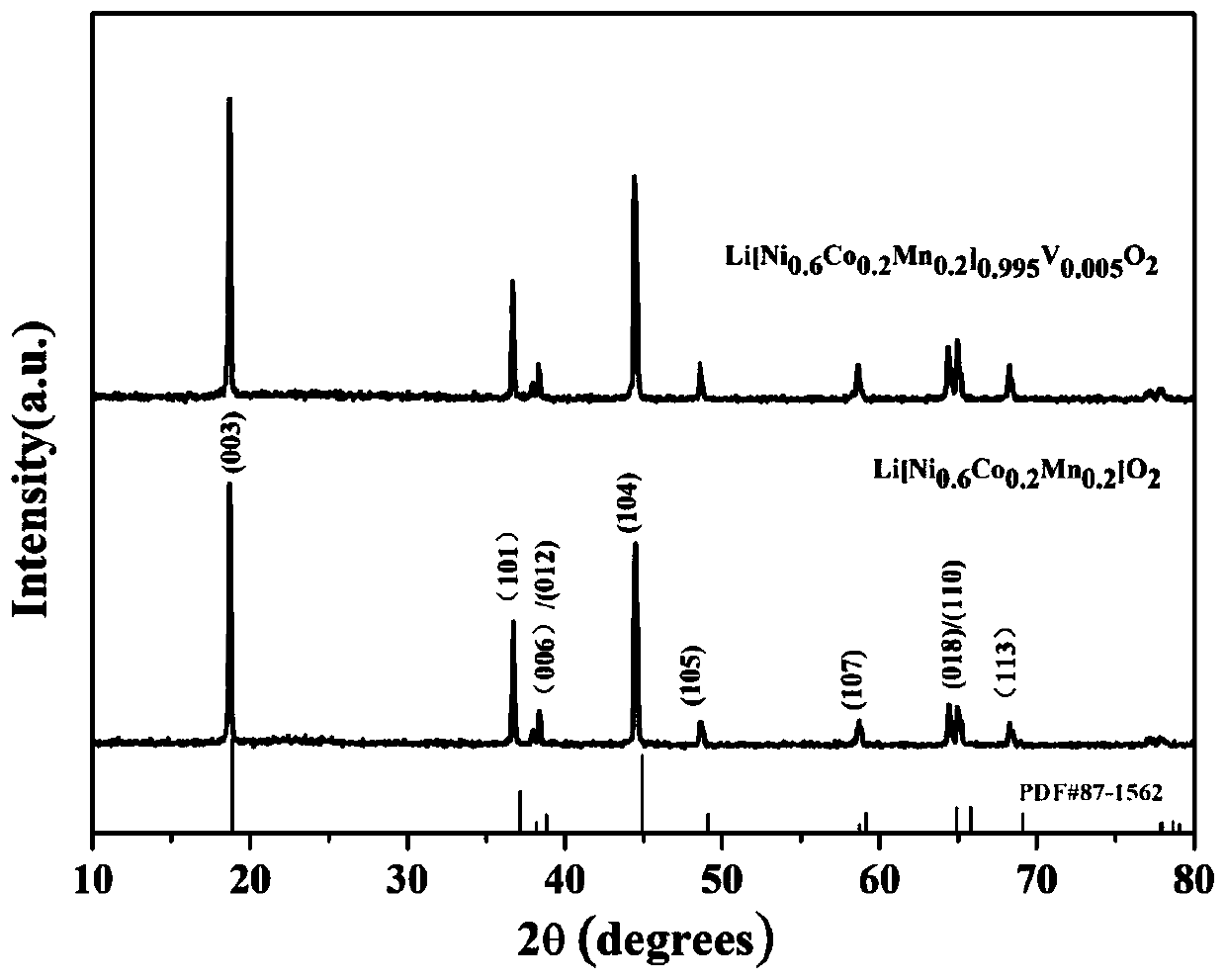

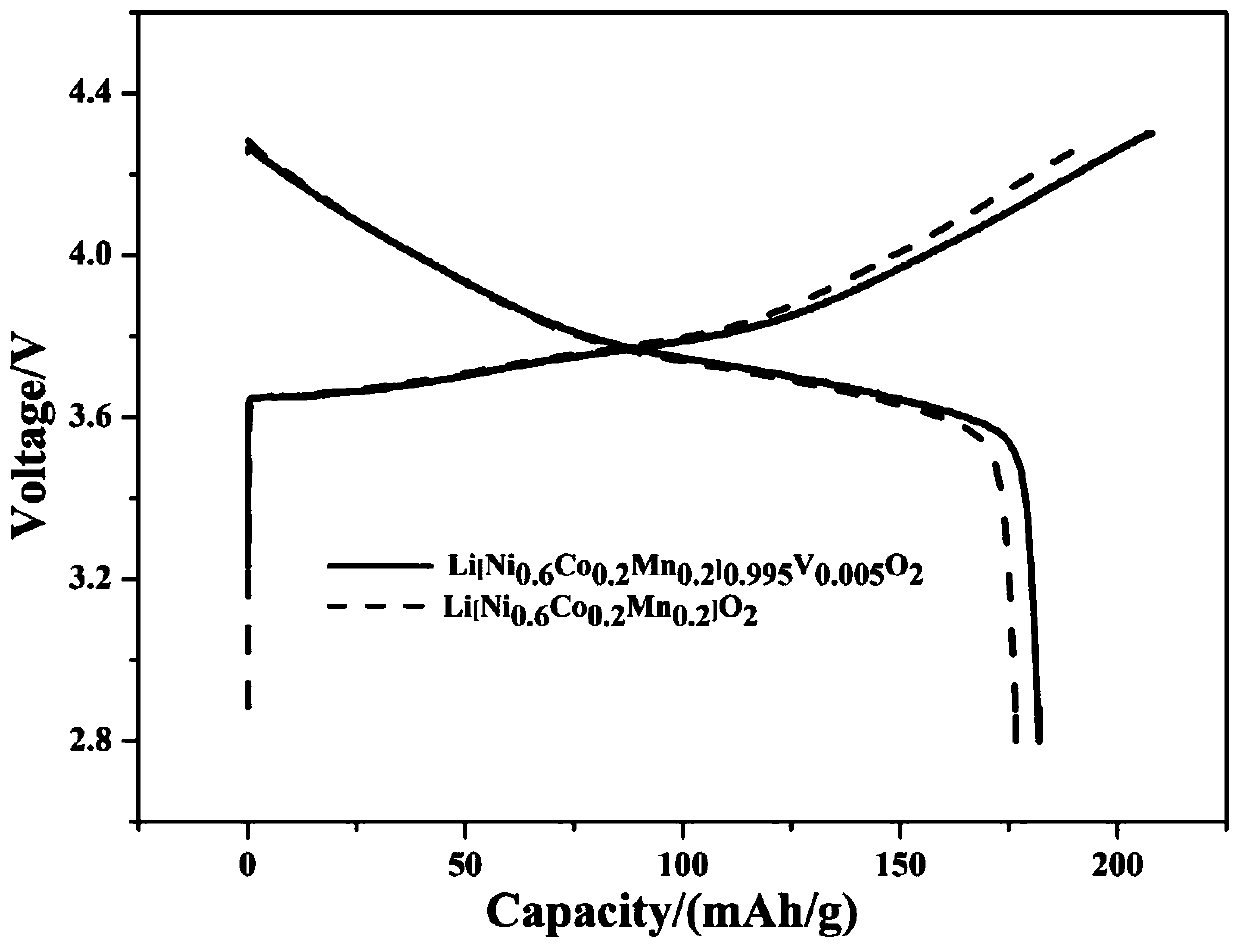

Vanadium-substituted ternary positive electrode material for lithium ion batteries and preparation method thereof

PendingCN109841827AHigh discharge specific capacityPromote circulationCell electrodesSecondary cellsAluminium-ion batteryLithium hydroxide

The invention provides a vanadium-substituted ternary positive electrode material for lithium ion batteries and a preparation method thereof. The vanadium-substituted ternary positive electrode material for lithium ion batteries is characterized by having a structural formula of Li[Ni0.6Co0.2Mn0.2]1-xVxO2, wherein x is greater than or equal to 0.005 and smaller than or equal to 0.01. The preparation method of the vanadium-substituted ternary positive electrode material for lithium ion batteries is characterized by comprising the steps of: weighing 225-228 weight parts of a hydrogen-oxygen precursor Ni0.6Co0.2Mn0.2(OH)2 and 110 weight parts of lithium hydroxide and 1.1-4.5 weight parts of vanadium pentaoxide, placing the substances in a mortar, and performing grinding until the substances are mixed evenly to obtain a powder precursor mixture; and conducting pressing into tablets, and performing calcination to obtain the vanadium-substituted Li[Ni0.6Co0.2Mn0.2]1-xVxO2 positive electrodematerial for lithium ion batteries. The lithium ion battery positive electrode material obtained by the invention shows high specific discharge capacity and good cycle performance, and has excellent application prospects in the future lithium ion battery energy storage system.

Owner:SHANGHAI INST OF TECH

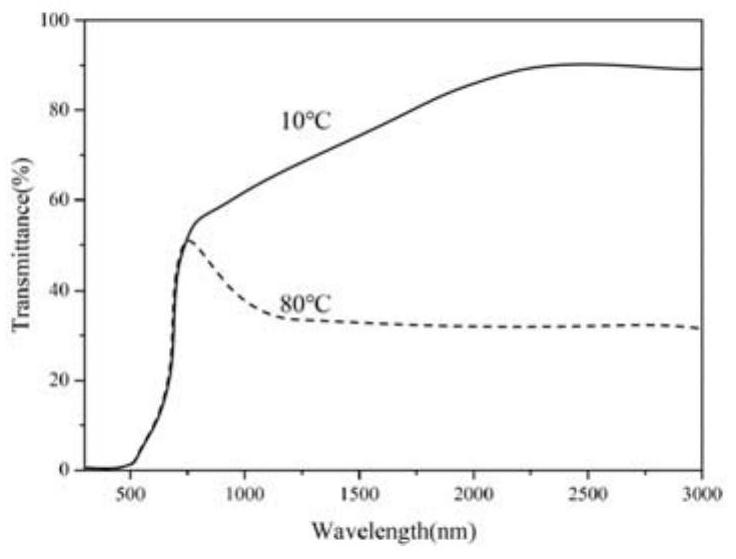

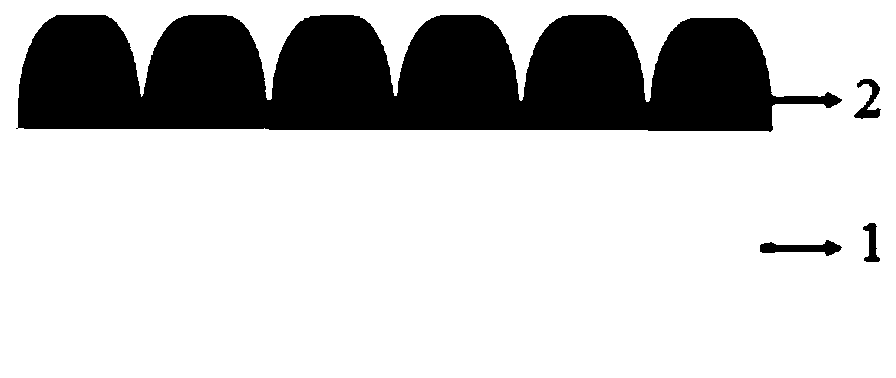

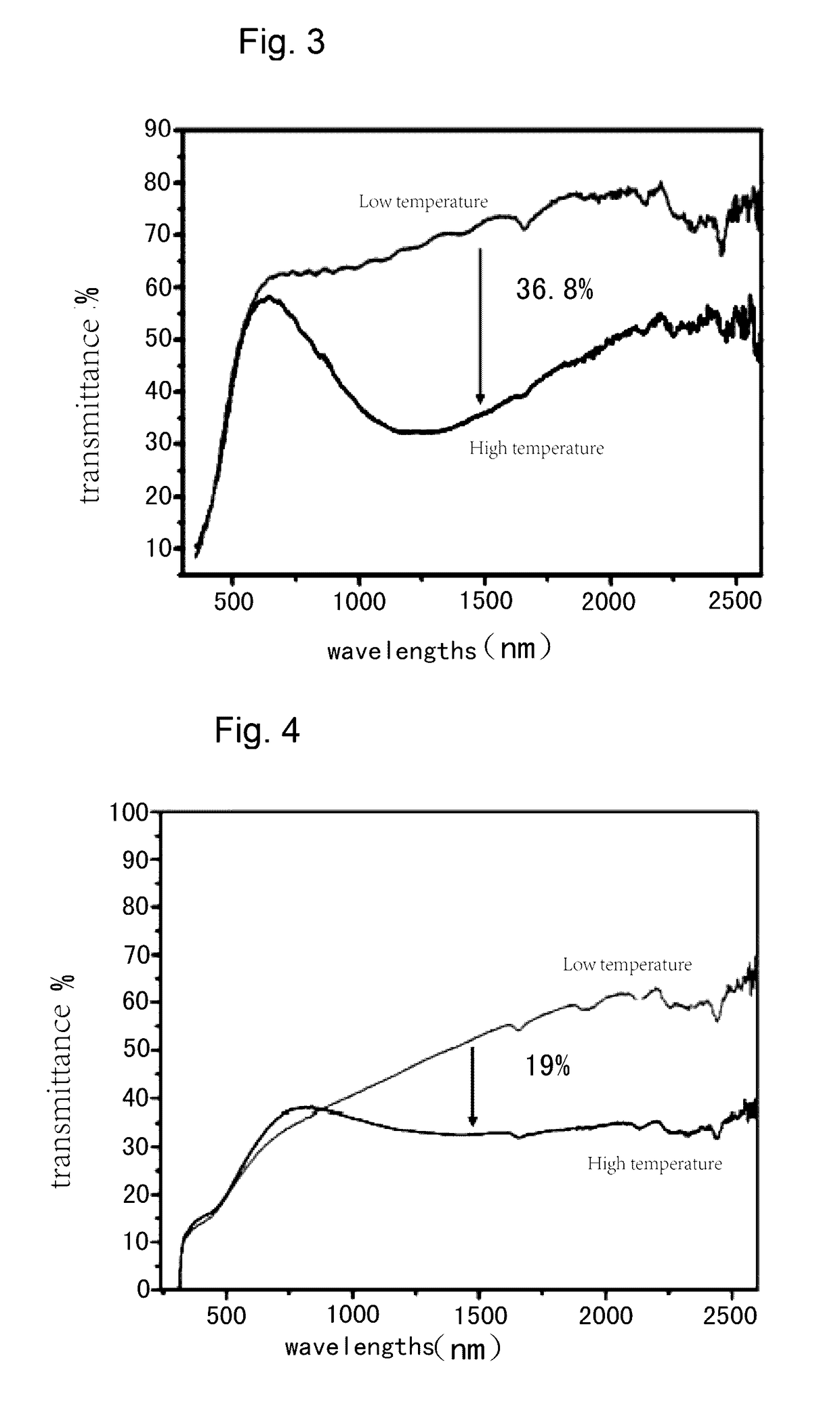

Moth-eye-structure-imitated vanadium dioxide intelligent window film and preparation method thereof

ActiveCN111139432ALower phase transition temperatureLow preparation temperatureVacuum evaporation coatingSputtering coatingVanadium dioxideSputtering

The invention discloses a moth-eye-structure-imitated vanadium dioxide intelligent window film and a preparation method thereof, and belongs to the field of intelligent windows. The problems that an existing VO2 film is low in low-temperature visible transmittance, the heat regulation and control capacity cannot meet the use requirement, the phase change temperature is high, and application of theexisting VO2 film in the field of intelligent windows is seriously restricted are solved. The moth-eye-structure-imitated vanadium dioxide intelligent window film is sequentially composed of a substrate layer and a VO2 layer from bottom to top. The preparation method comprises the following steps of 1, preparing a W-doped VO2 film through high-energy pulse magnetron sputtering; and 2, ion beam etching. The preparation method is used for the moth-eye-structure-imitated VO2 intelligent window thin film and the preparation thereof.

Owner:HARBIN INST OF TECH

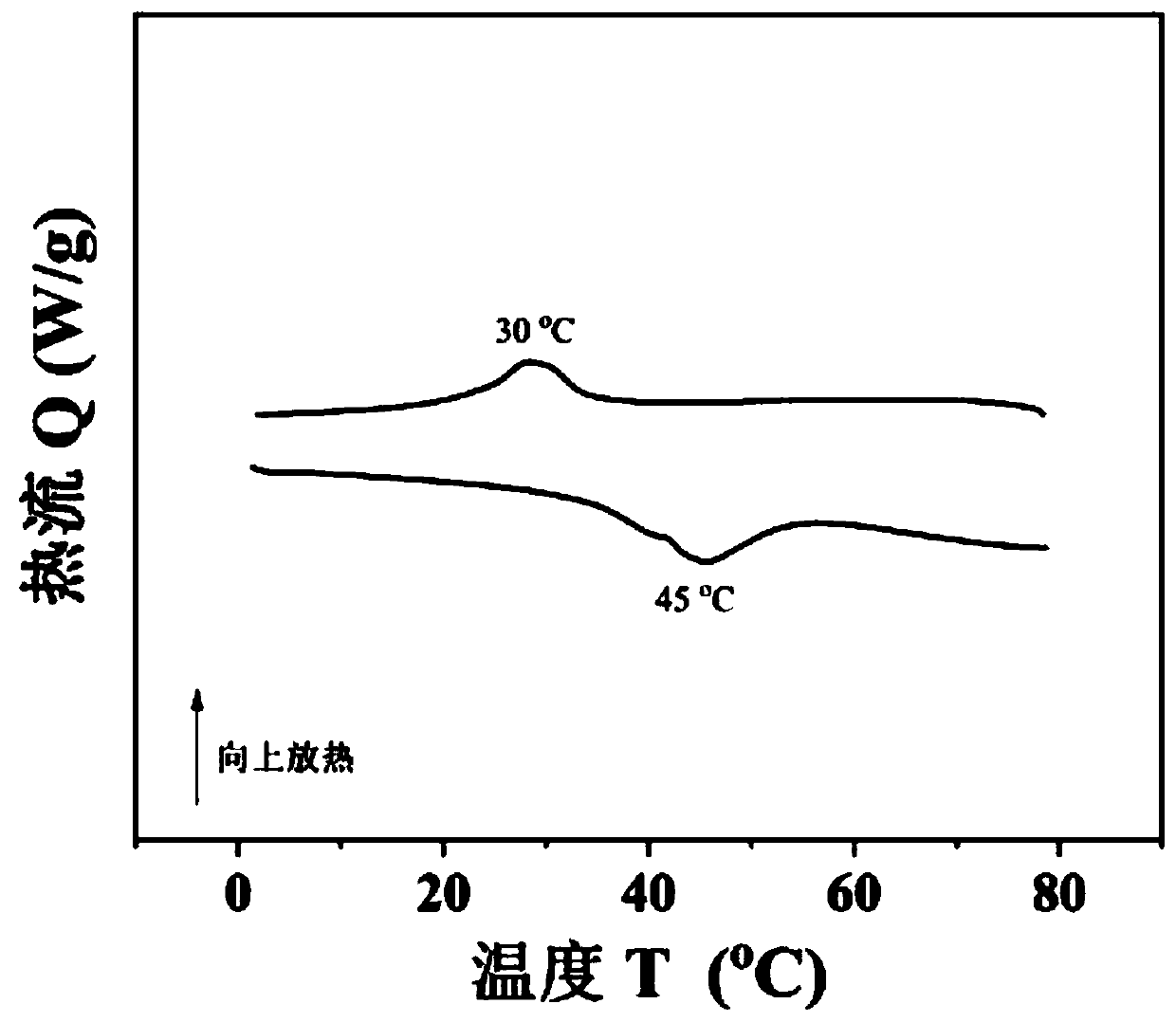

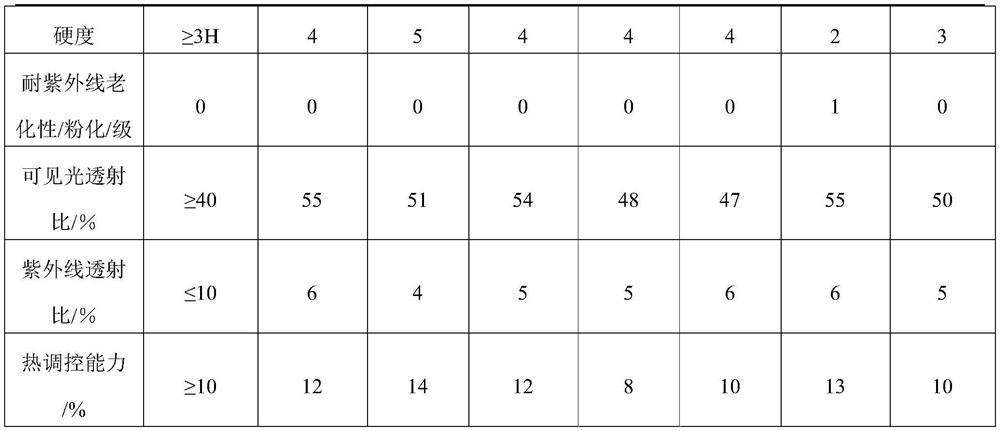

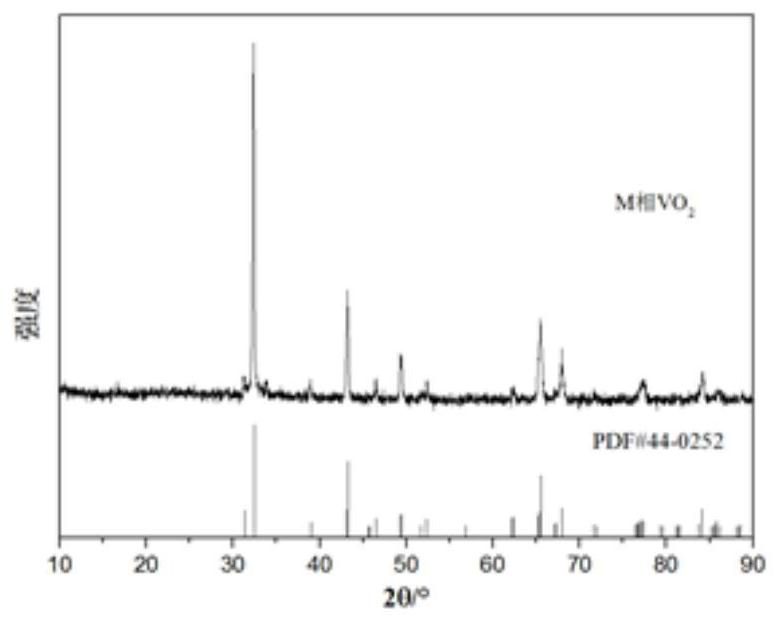

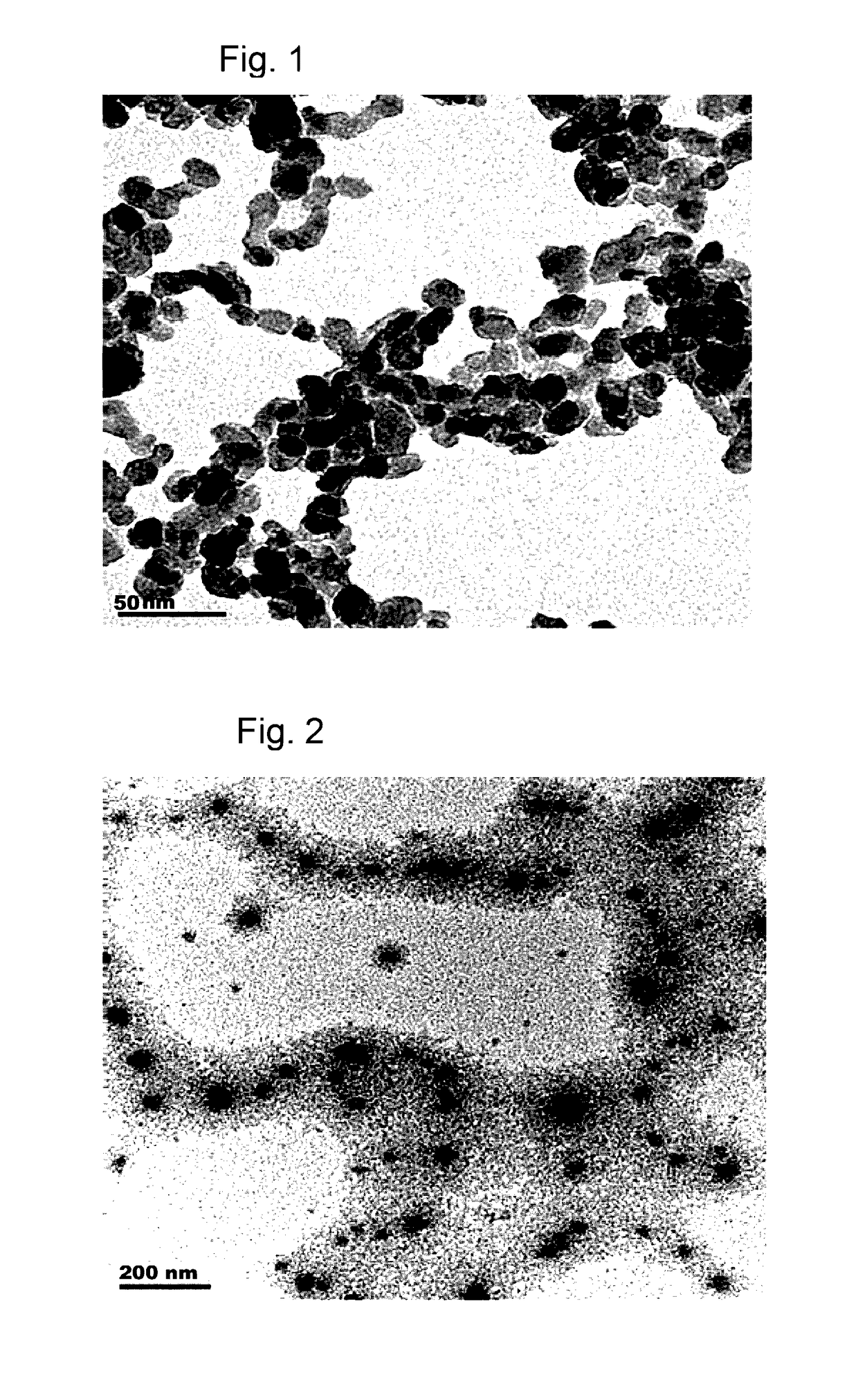

Method for preparing nano vanadium dioxide by reverse hydrolytic precipitation

InactiveCN112266018AFast preparationSmall particle sizeNanotechnologyVanadium oxidesVanadium dioxideOxyvanadium

The invention belongs to the technical field of preparation of vanadium dioxide, and particularly relates to a method for preparing nano vanadium dioxide through reverse hydrolytic precipitation. Aiming at the problem that nano vanadium dioxide with high crystallinity, good homogeneity and small granularity is difficult to obtain when vanadium dioxide is prepared by an existing chemical precipitation method, the invention provides a method for preparing nano vanadium dioxide by reverse hydrolytic precipitation, which comprises the following steps: a, taking a sodium hydroxide solution, and dropwise adding a tetravalent vanadium solution while stirring until the pH value of the solution is 7-8.5; b, conducting centrifuging, washing, drying and grinding to obtain precursor powder; and c, adding an ethanol solution, carrying out hydrothermal reaction for 12-24 hours, conducting cooling to room temperature, and conducting centrifuging and separating to obtain M-phase VO2 powder. The methodis simple in process, convenient to operate and low in preparation cost, a large amount of vanadium dioxide can be rapidly prepared, VO2 has the advantages of being high in purity, uniform in particle size distribution and good in crystallinity, and VO2 can be widely applied to the fields of intelligent windows, optoelectronic switches, thermistors and the like.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Preparation method and application of oxyvanadium phosphate catalyst

InactiveCN111420688AGood choiceImprove conversion ratePhysical/chemical process catalystsOrganic chemistryIsobutanolPtru catalyst

The invention relates to a preparation method of an oxyvanadium phosphate catalyst, which comprises the following steps: adding V2O5 into a mixed solution of isobutanol and benzyl alcohol, stirring and mixing, refluxing at 130-140 DEG C for 2-5 hours, cooling to 100-120 DEG C, keeping the temperature at 100-120 DEG C, adding H3PO4 with the mass concentration of 85-90% at the speed of 0.6-1.5 mL / min, heating to 130-140 DEG C, continuously refluxing for 10-14 hours, and filtering and washing the product to obtain an oxyvanadium phosphate precursor, and roasting the oxyvanadium phosphate precursor to obtain the oxyvanadium phosphate catalyst. According to the method, by controlling the adding process of the phosphorus source, the defect that the performance is improved by adding auxiliaries traditionally can be overcome, secondary pollution is avoided, the cost is reduced, and meanwhile the preparation process is simplified.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Process method for preparing vanadium dioxide nano-powder

InactiveCN112158883AUniform particle sizeUniform shapeMaterial nanotechnologyVanadium oxidesVanadium dioxideActive agent

The invention discloses a process method, particularly discloses a process method for preparing vanadium dioxide nano-powder, and belongs to the technical field of metallurgical production process manufacturing. The process method for preparing the vanadium dioxide nano-powder is short in preparation time, high in preparation efficiency and capable of saving energy and preparing the vanadium dioxide nano-powder which is uniform in morphology and high in system dispersity. The process method comprises the following steps: respectively atomizing an alkaline precipitator and a surfactant-containing tetravalent vanadate solution into fog drops with the particle size of less than 10 microns by adopting an ultrasonic atomizer, then putting the two atomized liquid drops into a reactor in an ultrasonic water bath for contact, making reacting to generate a VO(OH)2 precipitate, collecting the precipitate VO(OH)2 obtained by the reaction by using ethanol, and performing washing to obtain a VO(OH)2 precursor; carrying out ultrasonic dispersion on the collected and washed VO(OH)2 precursor and deionized water to form a suspension; and finally, carrying out hydrothermal crystallization treatmenton the suspension to obtain the nano vanadium dioxide with uniform granularity and dispersed monomers.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

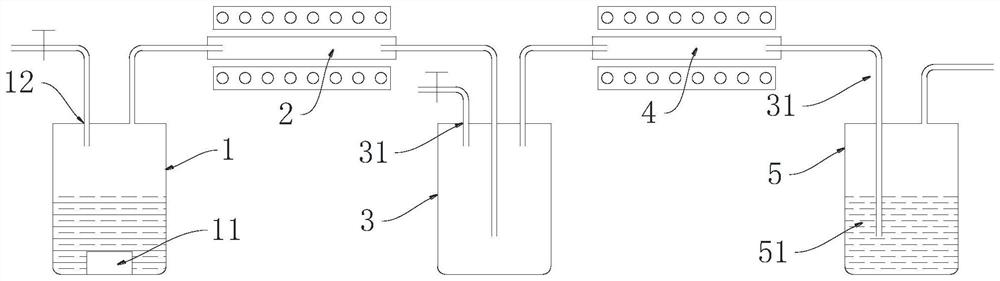

Method and device for preparing spherical VO2 nano powder by ultrasonic atomization method

ActiveCN112239229AHigh purityHigh crystallinityMaterial nanotechnologyVanadium oxidesVanadium dioxideTube furnace

The invention discloses a method and device for preparing spherical VO2 nano powder by an ultrasonic atomization method, relates to the field of preparation of inorganic functional materials, and aimsto solve the technical problem of providing a method and device capable of preparing vanadium dioxide powder. The method comprises the following steps: dissolving vanadium pentoxide in water to forma vanadium-containing solution with a certain concentration; atomizing the vanadium-containing solution, then fully drying in an inert gas atmosphere, reducing vanadium pentoxide by reducing gas undera heating condition, reacting to obtain vanadium dioxide powder, and collecting the powder. In order to promote dissolution of vanadium pentoxide, vanadium pentoxide is added into deionized water, heated and stirred, and then a co-solvent is added. After being atomized, the vanadium-containing solution firstly enters a first tubular furnace to be dried, then enters a buffer container, then entersa second tubular furnace to be subjected to a reduction reaction, and enters a collecting container after the reaction; wherein the buffer container is provided with a reducing gas inlet. The methodis suitable for preparing the vanadium dioxide powder with small granularity and high purity.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

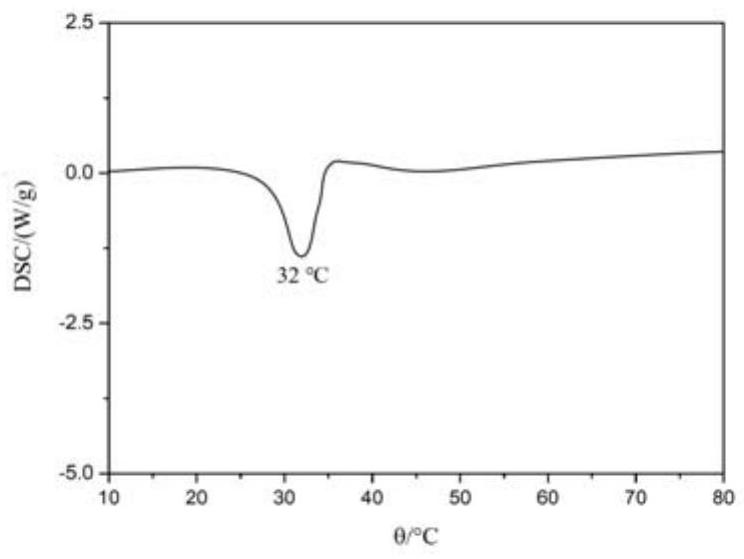

Composite film with heat insulation effect and preparation method

The invention discloses a composite film with a heat insulation effect and a preparation method, and belongs to the technical field of agricultural films. The composite film comprises the following materials in mass ratio: the mass ratio of a vanadium dioxide nano material to a polymer material is (0.0001-0.01): 1. According to the composite film provided by the invention, infrared rays can normally penetrate through the composite film at low temperature and can be blocked from penetrating through the composite film at high temperature, so that a problem of overhigh temperature in a film greenhouse in summer is effectively solved, and the yield of crops is effectively increased. The preparation method disclosed by the invention is simple and feasible, is suitable for industrial productionand can be widely applied to agricultural production, and raw materials are simple and easy to obtain.

Owner:UNIV OF JINAN +1

Method for preparing M-phase vanadium dioxide nano-powder by salt-assisted ultrasonic pyrolysis method

ActiveCN112209442AGood particle size dispersionReduce crystallinityNanotechnologyVanadium oxidesVanadium dioxidePhysical chemistry

The invention relates to the field of preparation methods of inorganic functional materials, in particular to a method for preparing M-phase vanadium dioxide nano-powder by a salt-assisted ultrasonicpyrolysis method, and the preparing method is simple in synthesis process and short in flow and can be used for efficiently preparing monodisperse and high-purity nano-vanadium dioxide powder. The preparation method comprises the following steps: a, preparing a precursor solution: dissolving auxiliary salt and tetravalent vanadate in deionized water to prepare a precursor solution of a vanadium source, and carrying out ultrasonic dispersion treatment; and b, preparing M-phase vanadium dioxide nano-powder: putting the precursor solution prepared in the step a into an ultrasonic atomizer, conducting atomizing to generate fog drops, collecting the fog drops carried by carrier gas through a vertical tube furnace and a high-voltage electrostatic collector, then putting the collected powder intodeionized water, and performing ultrasonic treatment and filtration, and conducting drying in vacuum to obtain the M-phase vanadium dioxide nano-powder. The preparation method is particularly suitable for the preparation process of the M-phase vanadium dioxide nano-powder.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

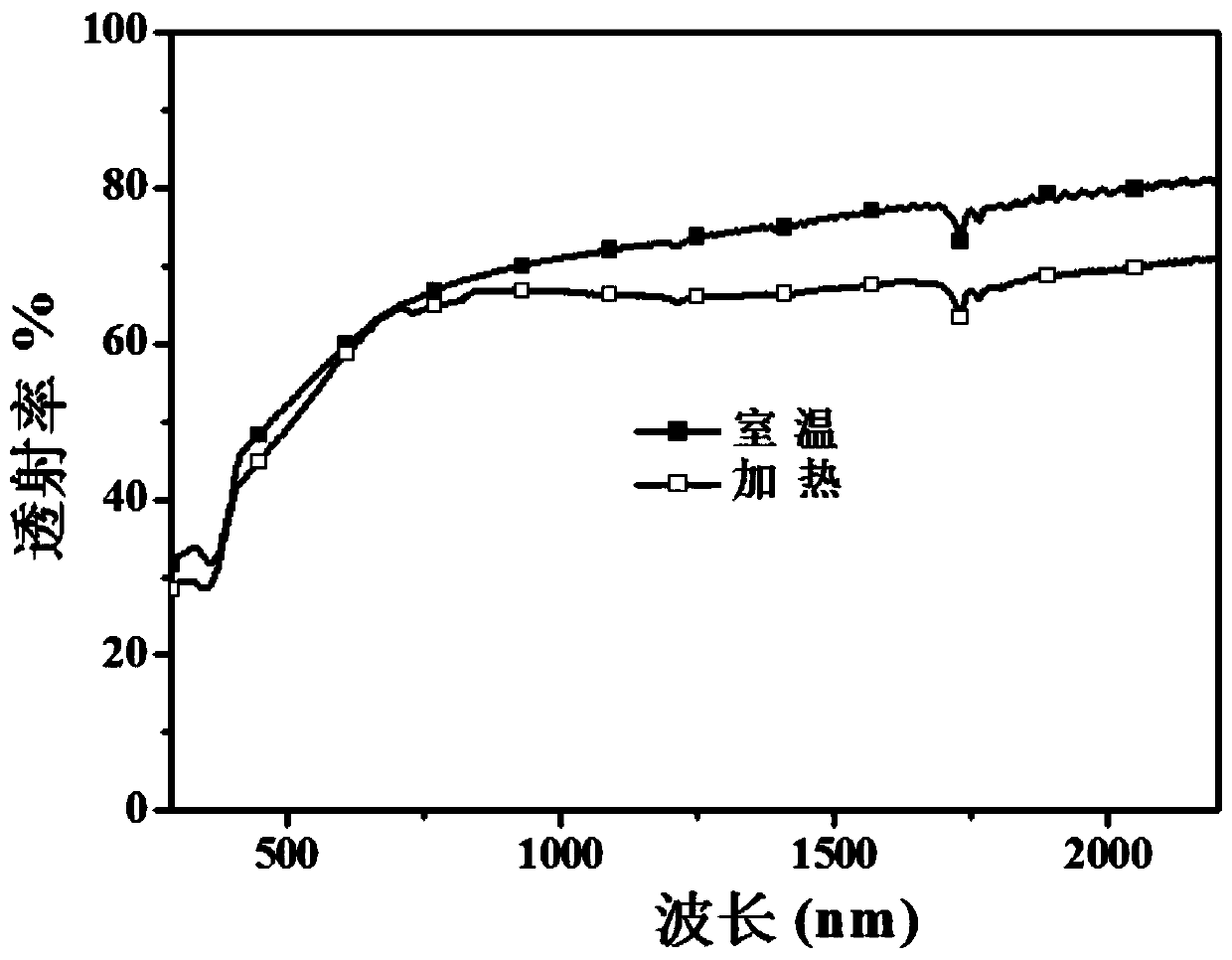

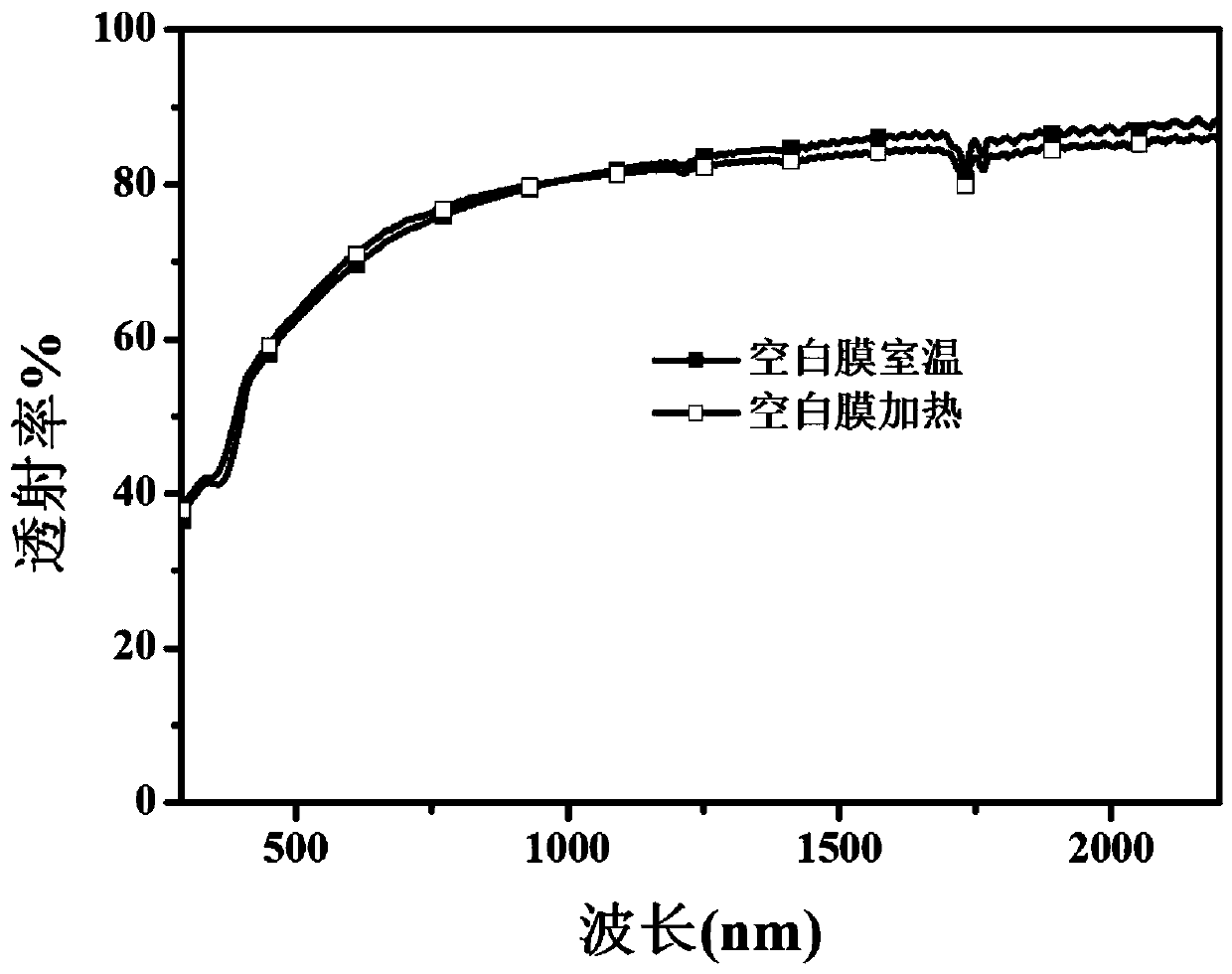

Methods for preparing vanadium dioxide composite powders, vanadium dioxide powder slurry, and vanadium dioxide coating for intelligent temperature control

ActiveUS9650520B2Simple and convenient for mass productionImprove applicabilityGroup 5/15 element organic compoundsGroup 3/13 element organic compoundsVanadium dioxideInfrared

A vanadium dioxide coating for intelligent temperature control is formed by mixing a vanadium dioxide powder slurry, a polymer emulsion, and coating additives, and then coating the mixture onto a substrate. The vanadium dioxide powdery slurry comprises vanadium dioxide composite powders and a dispersion medium, the composite powders comprising vanadium dioxide nanopowders having a chemical composition of V1−xMxO2, and the surface of the vanadium dioxide nanopowders being attached to organic modified long-chain molecules, wherein M is a doped element, and 0≦x≦0.5. Through using the vanadium dioxide powders and the slurry thereof having an organic modified surface, the coating has higher visible light transmittance, can almost completely screen ultraviolet rays, and simultaneously intelligently adjust infrared rays.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

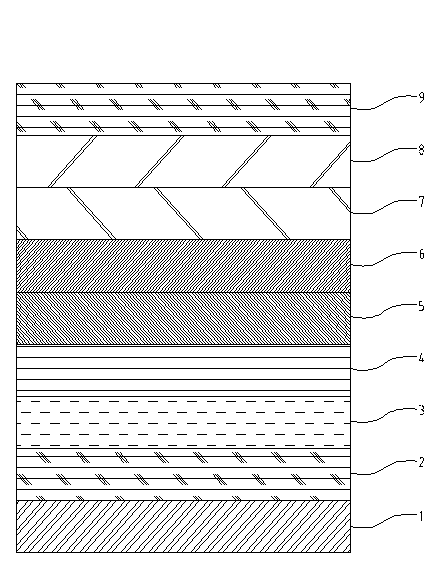

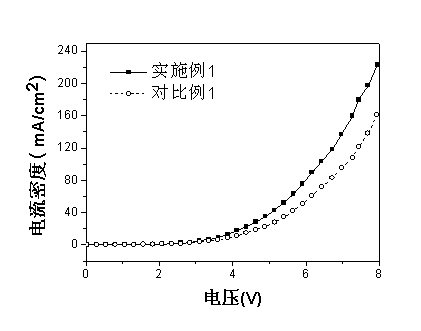

Organic light emission diode device and preparation method thereof

InactiveCN104218153ASmall driving currentImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionDriving current

The invention discloses an organic light emission diode device. The organic light emission diode device comprises a substrate, a conductive anode, a first hole injection auxiliary layer, a second hole injection auxiliary layer, a hole transmission layer, a luminous layer, an electronic transmission layer, an electronic injection layer and a cathode, which are stacked in sequence, wherein the first hole injection auxiliary layer is made of 2,3,6,7,10,11-hexacyano-1,4,5,8,9,12-hexaazatriphenylene, and the second hole injection auxiliary layer is made of zinc phthalocyanine, copper phthalocyanine, oxyvanadium phthalocyanine or titanyl phthalocyanine. The invention also discloses a preparation method of the organic light emission diode device. According to the preparation method of the organic light emission diode device, through adding two layers of hole injection auxiliary layers in the conductive anode and the hole transmission layer for improving the hole injection capacity, the organic light emission diode device prepared by utilizing the preparation method of the organic light emission diode device has the advantages of small drive current and high luminous efficiency.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com