Organic light emission diode device and preparation method thereof

An electroluminescent device and luminescent technology, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of low device life and low luminous efficiency of organic electroluminescent devices, and achieve film-forming quality Good, beneficial to the transmission process and the effect of increasing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

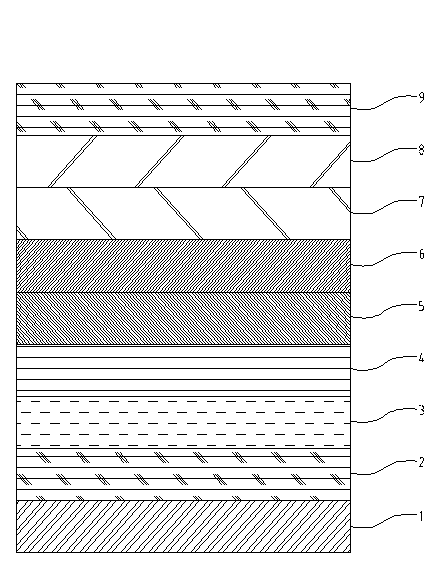

[0028] A method for preparing an organic electroluminescent device, comprising the following steps:

[0029] (1) A glass substrate is provided, and a conductive anode is deposited on the surface of the glass substrate by electron beam evaporation, and the conductive anode is Ag, among which,

[0030] The pressure when preparing the conductive anode by electron beam evaporation is 1×10 -3 Pa, the energy density of electron beam evaporation is 10W / cm2 , the evaporation rate is 0.01 nm / s, and the thickness of the conductive anode is 20nm.

[0031] (2) Vacuum-deposit the first hole injection auxiliary layer on the surface of the conductive anode. The material of the first hole injection auxiliary layer is 2,3,6,7,10,11-hexacyano-1,4,5, 8,9,12-hexaazatriphenylene (HAT-CN), the pressure of the first hole injection auxiliary layer evaporation is 1×10 -3 Pa, the evaporation rate is 0.1nm / s, and the evaporation thickness is 1nm.

[0032] (3) The second hole injection auxiliary ...

Embodiment 2

[0043] A method for preparing an organic electroluminescent device, comprising the following steps:

[0044] (1) A glass substrate is provided, and a conductive anode is deposited on the surface of the substrate through vacuum thermal resistance evaporation, and the conductive anode is selected from Al. Among them,

[0045] The pressure of conductive anode evaporation is 1×10 -5 Pa, the evaporation rate is 5nm / s.

[0046] (2) Vacuum-deposit the first hole injection auxiliary layer on the surface of the conductive anode. The material of the first hole injection auxiliary layer is 2,3,6,7,10,11-hexacyano-1,4,5, 8,9,12-hexaazatriphenylene (HAT-CN), the first hole injection auxiliary layer was evaporated at a pressure of 1×10 -5 Pa, the evaporation rate is 1nm / s, and the evaporation thickness is 5nm.

[0047] (3) The second hole injection auxiliary layer is vacuum evaporated on the surface of the first hole injection auxiliary layer. The material of the second hole injection au...

Embodiment 3

[0058] A method for preparing an organic electroluminescent device, comprising the following steps:

[0059] (1) A glass substrate is provided, and a conductive anode is prepared by electron beam evaporation on the surface of the glass substrate. The conductive anode is selected from Au, wherein,

[0060] The pressure when the conductive anode is evaporated by electron beam is 1×10 -4 Pa, the energy density of electron beam evaporation is 100W / cm 2 , the evaporation rate is 1nm / s, and the thickness of the conductive anode is 100nm.

[0061] (2) Vacuum-deposit the first hole injection auxiliary layer on the surface of the conductive anode. The material of the first hole injection auxiliary layer is 2,3,6,7,10,11-hexacyano-1,4,5, 8,9,12-hexaazatriphenylene (HAT-CN), the first hole injection auxiliary layer was evaporated at a pressure of 1×10 -4 Pa, the evaporation rate is 0.5nm / s, and the evaporation thickness is 2nm.

[0062] (3) The second hole injection auxiliary layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com