Preparation method and application of oxyvanadium phosphate catalyst

A vanadyl phosphate catalyst, n-butane technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of unstable VPO catalyst batch performance and unclear key factors, and achieve excellent Selectivity and conversion, simplified process, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

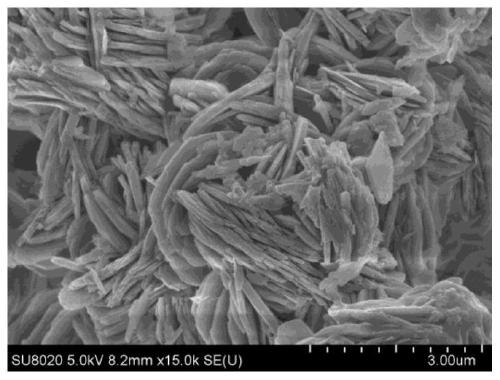

[0021] The embodiment of the present invention provides a kind of preparation method of vanadyl phosphate catalyst, it comprises the following steps:

[0022] S01: set V 2 o 5 Add to the mixture of isobutanol and benzyl alcohol, stir and mix, reflux at 130°C-140°C for 2-5 hours, then cool down to 100°C-120°C.

[0023] S02: Maintain 100°C to 120°C, add H with a mass concentration of 85% to 90% at a rate of 0.6 to 1.6mL / min 3 PO 4 Afterwards, the temperature was raised to 130-140°C and continued to reflux for 10-14 hours, and the product was filtered and washed to obtain the vanadyl phosphate precursor;

[0024] S03: roasting the vanadyl phosphate precursor to obtain the vanadyl phosphate catalyst.

[0025] Preferably, the volume ratio of isobutanol to benzyl alcohol is (3-5):1, such as 3:1, 3.2:1, 3.5:1, 4:1, 4.5:1, 4.7:1, 4.9:1 , or 5:1, etc.

[0026] Preferably, the V 2 o 5 The concentration is 0.02g / mL~0.12g / mL, such as 0.02g / mL, 0.04g / mL, 0.06g / mL, 0.07g / mL, 0.08g / m...

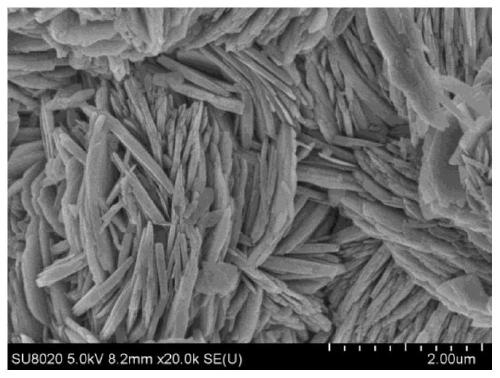

Embodiment 1

[0044] Preparation of vanadyl phosphate catalyst:

[0045] (1) Weigh 10g V 2 o 5 Place in a 250mL three-neck flask, add a mixture of 80mL isobutanol and 20mL benzyl alcohol, stir and mix evenly, reflux at 135°C for 3h and then cool down to 110°C.

[0046] (2) Keeping at 110°C, add 7.53mL of 85% H2 dropwise within 7min 3 PO 4 , and continued to reflux for 12 hours at a temperature of 135° C. The product was filtered, washed with absolute ethanol to obtain a blue precipitate, and dried in air at 120° C. for 24 hours to obtain a vanadyl phosphate precursor.

[0047] (3) The obtained vanadyl phosphate precursor powder is compressed under a pressure of 15MPa, crushed, and 20-40 mesh catalyst particles are sieved, and then the catalyst particles are mixed in n-butane / oxygen at a volume ratio of 1.5:17:81.5 / Nitrogen reaction gas atmosphere from room temperature to 430° C. for 12 hours at a rate of 2° C. / min to obtain the vanadyl phosphate catalyst.

[0048] Detection:

[0049...

Embodiment 2

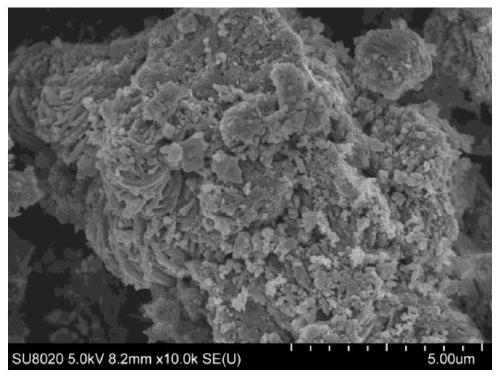

[0052] Preparation of vanadyl phosphate catalyst:

[0053] (1) Weigh 10g V 2 o 5 Place in a 250mL three-neck flask, add a mixture of 80mL isobutanol and 20mL benzyl alcohol, stir and mix evenly, reflux at 135°C for 3h and then cool down to 110°C.

[0054] (2) Keeping at 110°C, add 7.21mL of 87% H2 dropwise within 6.7min 3 PO 4 , and continued to reflux for 12 hours at a temperature of 135° C. The product was filtered and washed with absolute ethanol to obtain a blue-black precipitate, which was dried in air at 120° C. for 24 hours to obtain a vanadyl phosphate precursor.

[0055] (3) Press the obtained vanadyl phosphate precursor powder into tablets under a pressure of 15MPa, crush it, and sieve the catalyst particles of 20-40 meshes, and then heat the catalyst particles from room temperature at a rate of 2°C / min under a reaction gas atmosphere Raise the temperature to 430°C for in-situ activation for 12 hours to obtain a vanadyl phosphate catalyst.

[0056] Detection: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com