Method and device for preparing spherical VO2 nano powder by ultrasonic atomization method

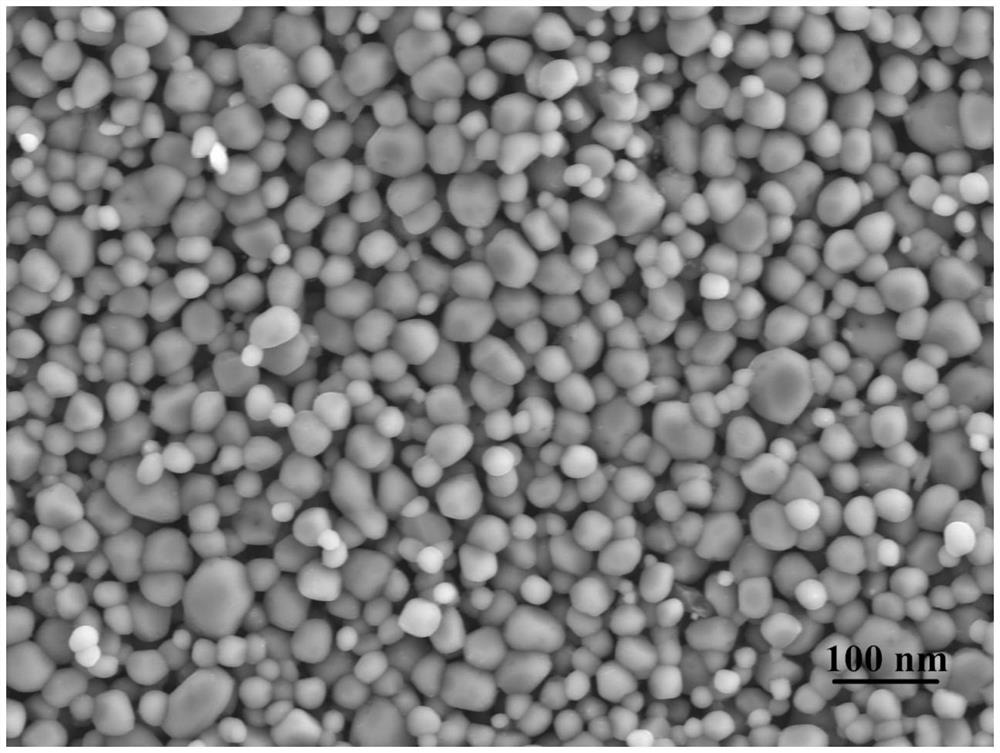

An ultrasonic atomization, nano-powder technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of slow reaction and low comprehensive yield, and achieve good crystallinity and sufficient React, avoid the effect of sticking to the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

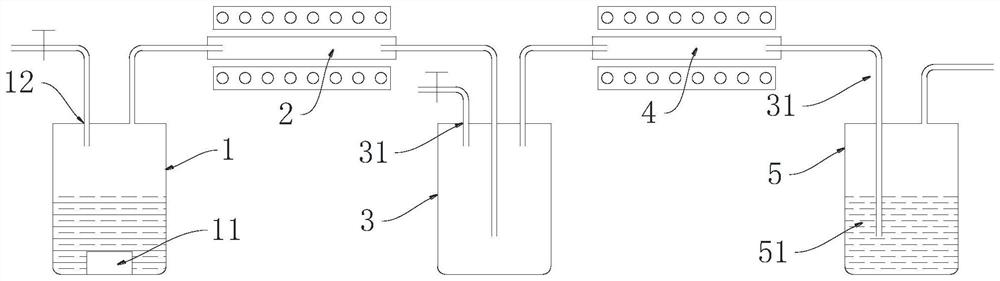

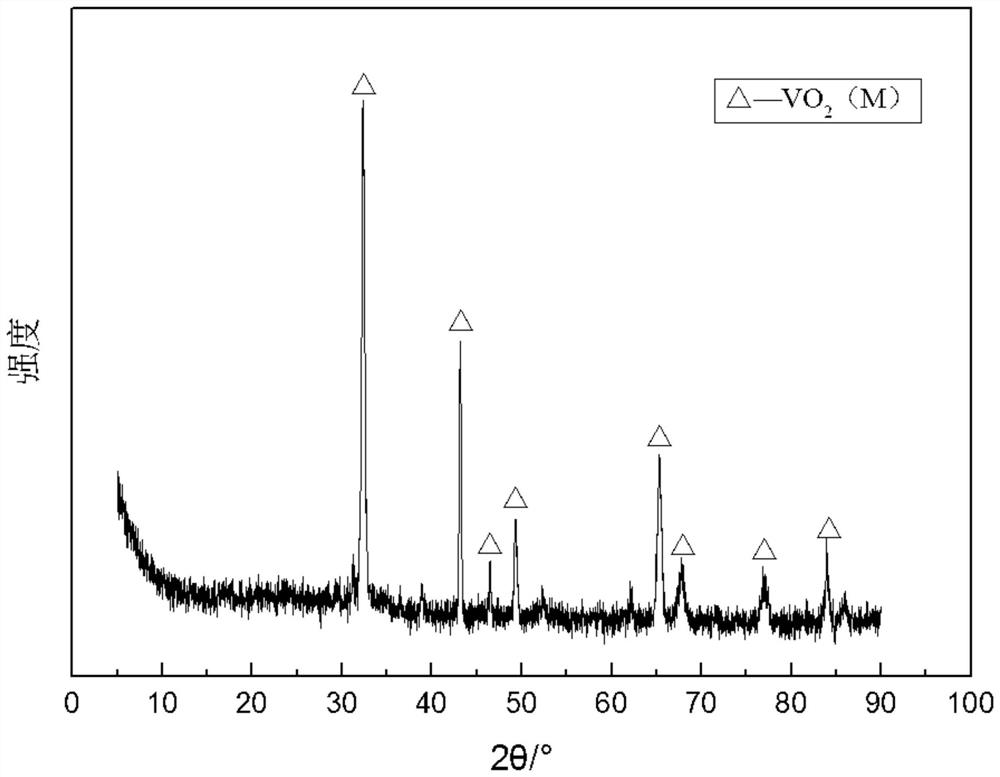

[0037] Weigh 4.55g of vanadium pentoxide, add deionized water to make the volume up to 1.00L, stir in a water bath at 80°C for 4 hours, then add ammonia water drop by drop until the vanadium pentoxide is completely dissolved, and re-volume the solution to 1.00 L and load figure 1 In the atomizing container 1 of the device shown. First, through the inert gas inlet 12, continue to feed argon for 30 minutes. After 30 minutes, continue to feed argon and open the first tube furnace 2 and the second tube furnace 4. The first tube furnace 2 rises to 100 ° C and the second tube furnace When the furnace 4 rises to 500°C, the ultrasonic atomizer 11 is turned on, and H is introduced into the buffer container 3 through the reducing gas inlet 31 at the same time. 2 gas. When the vanadium-containing solution in the atomization container 1 is sprayed, close the reducing gas inlet 31, close the first tube furnace 2 and the second tube furnace 4 to complete the heat preservation, and continu...

Embodiment 2

[0040] Weigh 10.50g of vanadium pentoxide, add deionized water to make it up to 1.00L, stir in a water bath at 90°C for 6 hours, then add ammonia water drop by drop until the vanadium pentoxide is completely dissolved, and re-set the volume of the solution to 1.00 L and load figure 1 In the atomizing container 1 of the device shown. First, argon is continuously fed through the inert gas inlet 12 for 30 minutes, and after 30 minutes, the argon is continued and the first tube furnace 2 and the second tube furnace 4 are turned on. The first tube furnace 2 rises to 150 ° C and the second tube furnace When the furnace 4 rises to 550°C, the ultrasonic atomizer 11 is turned on, and at the same time, NH is introduced into the buffer container 3 through the reducing gas inlet 31 3 gas. When the vanadium-containing solution in the atomization container 1 is sprayed, close the reducing gas inlet 31, close the first tube furnace 2 and the second tube furnace 4 to complete the heat prese...

Embodiment 3

[0042] Weigh 18.20g of vanadium pentoxide, add deionized water to make it up to 1.00L, stir in a water bath at 100°C for 8 hours, then add ammonia water drop by drop until the vanadium pentoxide is completely dissolved, and re-set the volume of the solution to 1.00 L and load figure 1 In the atomizing container 1 of the device shown. First, through the inert gas inlet 12, continue to feed argon for 30 minutes. After 30 minutes, continue to feed argon and open the first tube furnace 2 and the second tube furnace 4. The first tube furnace 2 rises to 200 ° C and the second tube furnace When the furnace 4 rises to 60°C, the ultrasonic atomizer 11 is turned on, and CO gas is introduced into the buffer container 3 through the reducing gas inlet 31 at the same time. When the vanadium-containing solution in the atomization container 1 is sprayed, close the reducing gas inlet 31, close the first tube furnace 2 and the second tube furnace 4 to complete the heat preservation, and contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com