Composite film with heat insulation effect and preparation method

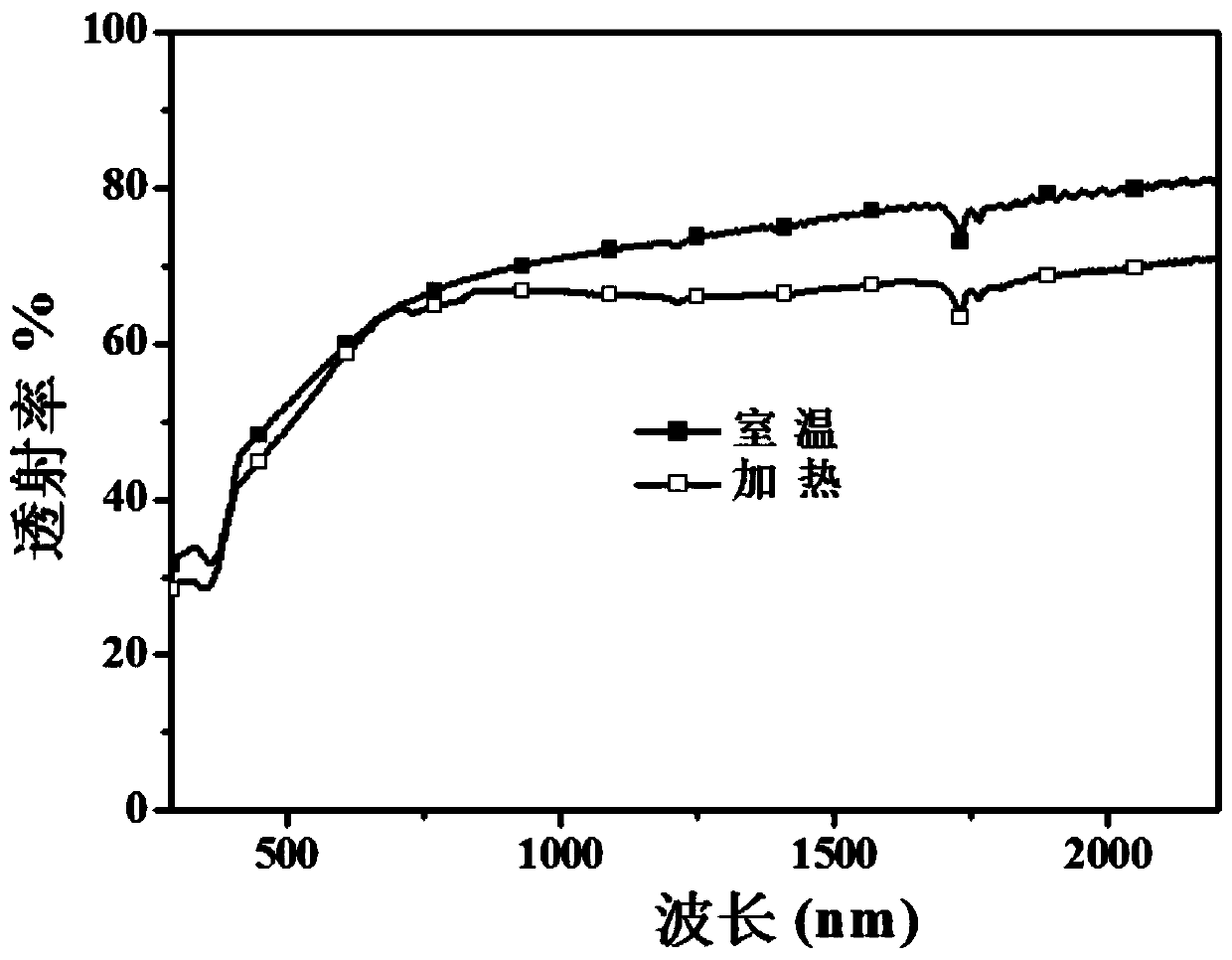

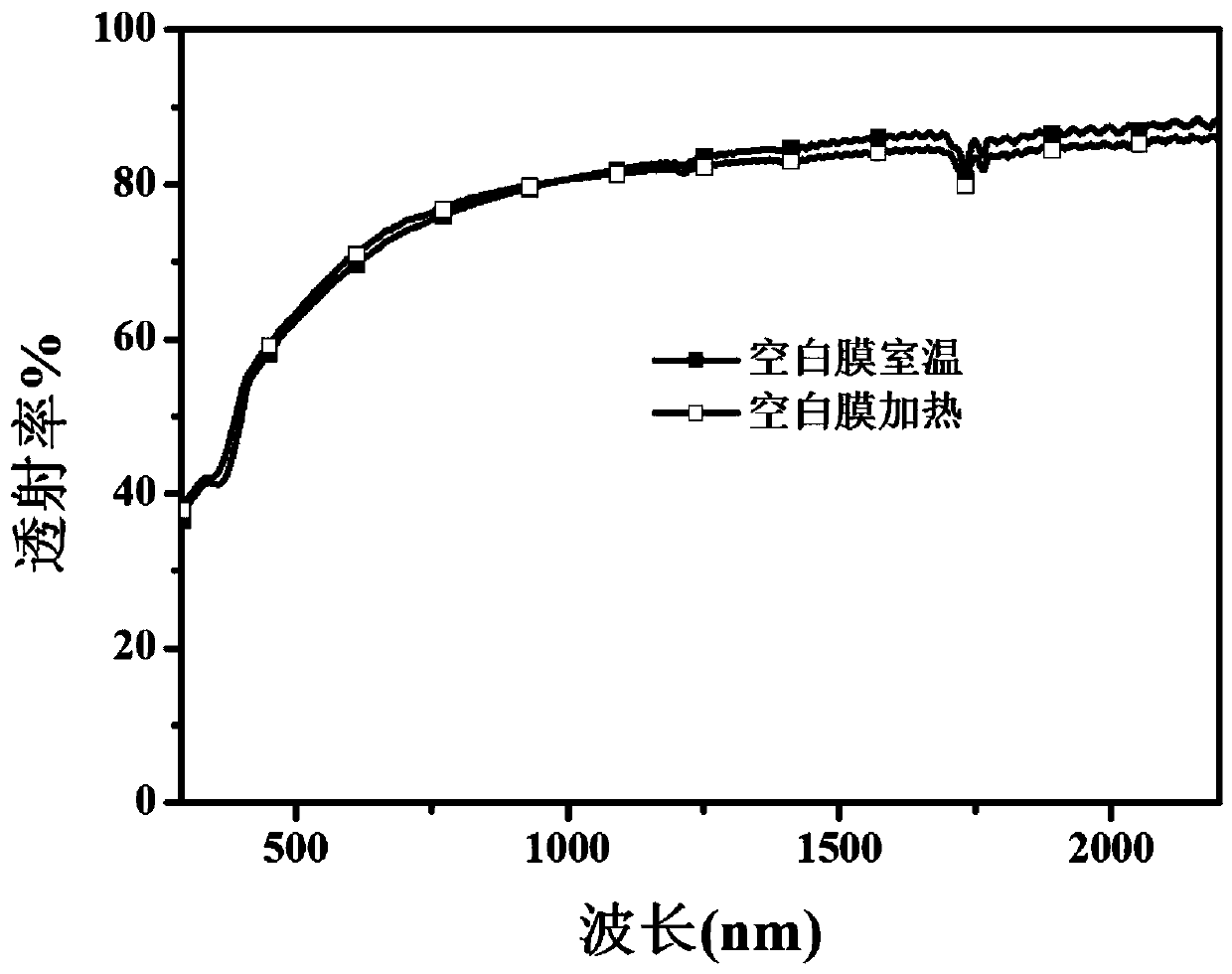

A technology of composite film and heat insulation effect, which is applied in the field of composite film with heat insulation effect and its preparation, which can solve the problems that agricultural film is not easy to heat insulation, and achieve the effects of simple and easy preparation method, increased production, and simple and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 1g of monoclinic vanadium dioxide with a particle size of 50nm to 500nm and 1kg of polyethylene into an internal mixer, and banbury at 140°C for 2 hours to obtain a block polymer melt;

[0029] The bulk polymer melt is added to the forced feeder, and the block polymer is added to the single-screw extruder through the forced feeder. The die head temperature of the single-screw extruder is 230 ° C, and the rotation speed is 100 rpm. extrusion of polymer strips;

[0030] The strip polymer is added to the pelletizer, and the granular polymer masterbatch with uniform size is obtained under the rotating speed of 600rpm;

[0031] Add the granular polymer masterbatch into the hopper of the blown film machine, so that the barrel temperature in the three temperature zones of the blown film machine is 180°C, 200°C, and 240°C, the head temperature is 250°C, and the connector temperature is 200°C , the screw rotation frequency was 15.00 Hz, and the winding speed was 150 rpm to ...

Embodiment 2

[0033] Add 3g of monoclinic vanadium dioxide with a particle size of 50nm to 500nm and 1kg of polypropylene into an internal mixer, and banbury at 170°C for 1 hour to obtain a block polymer melt;

[0034] The bulk polymer melt is added to the forced feeder, and the block polymer is added to the single-screw extruder through the forced feeder. The die head temperature of the single-screw extruder is 200 ° C, and the rotation speed is 120 rpm. extrusion of polymer strips;

[0035] Add the strip polymer into the pelletizer at a speed of 800rpm to obtain granular polymer masterbatches of uniform size;

[0036] Add the granular polymer masterbatch into the hopper of the blown film machine, so that the barrel temperature in the three temperature zones of the blown film machine is 200°C, 200°C, and 230°C, the temperature of the head is 200°C, and the temperature of the connector is 240°C , the screw rotation frequency was 18.00 Hz, and the winding speed was 120 rpm to prepare a poly...

Embodiment 3

[0038] Add 5g of monoclinic vanadium dioxide with a particle size of 50nm to 500nm and 1kg of polyvinyl chloride into the internal mixer, and banbury at 220°C for 0.5h to obtain a block polymer melt;

[0039] The bulk polymer melt is added to the forced feeder, and the block polymer is added to the single-screw extruder through the forced feeder. The die head temperature of the single-screw extruder is 200 ° C, and the rotation speed is 150 rpm. extrusion of polymer strips;

[0040] Add the strip-shaped polymer into the pelletizer at a speed of 1000rpm to obtain granular polymer masterbatches with uniform size;

[0041] Add the granular polymer masterbatch into the hopper of the blown film machine, so that the barrel temperature in the three temperature zones of the blown film machine is 180°C, 200°C, and 240°C, the head temperature is 190°C, and the connector temperature is 200°C , the screw rotation frequency was 10.00 Hz, and the winding speed was 120 rpm to prepare a poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com