Aero-engine turbine rotor cooling heat management system

A thermal management system, aero-engine technology, applied in the cooling of the engine, the cooling of the turbine/propulsion unit, the turbine/propulsion fuel delivery system, etc., can solve the problems of over-temperature of the turbine rotor of the aero-engine, and achieve easy transformation and implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below by means of specific embodiments:

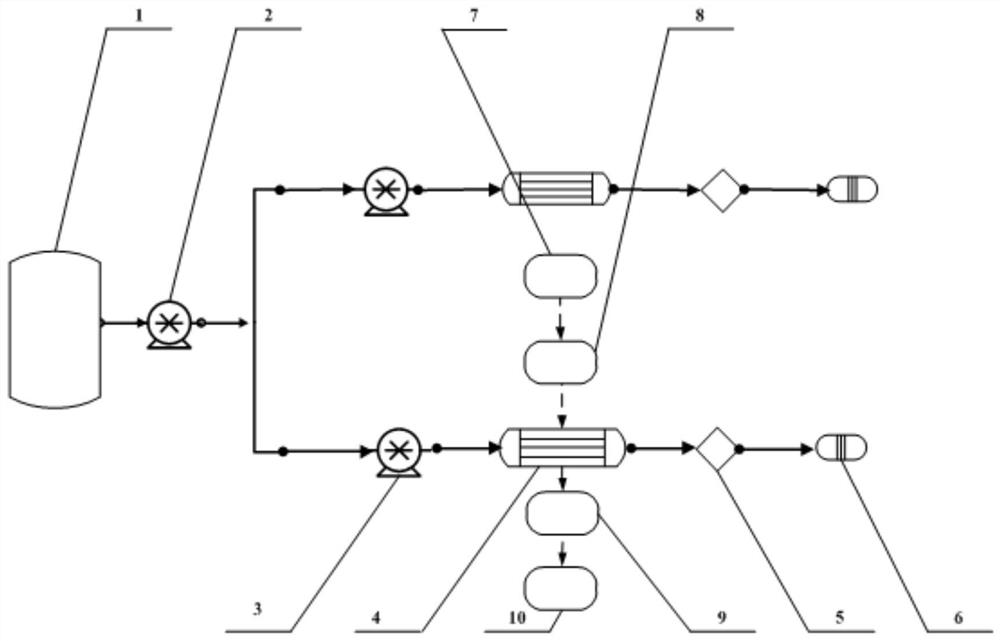

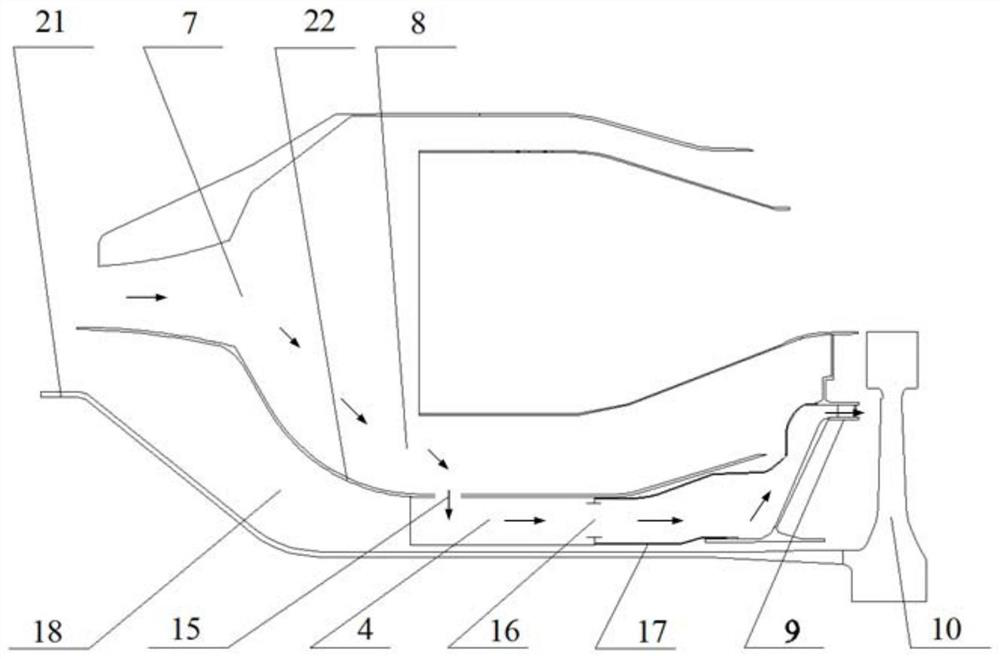

[0027] figure 1 Schematic diagram of the fuel flow path of the thermal management system, such as figure 1 As shown, in the thermal management system, the air-fuel heat exchanger 4 is added. When flying at high speed, the fuel in the fuel tank flows into the main fuel flow path and the afterburner fuel flow path respectively after passing through the first booster pump 2. The specific flow path The fuel flows from the fuel tank 1 through the first booster pump 2, and then divides into two paths, one into the main fuel flow path and the other into the afterburner fuel flow path (large fuel flow). In the afterburner fuel flow path, the afterburner fuel first enters the air-oil heat exchanger 4 from the second booster pump 3, then flows through the large-volume oil path to form the attachment 5, and finally enters the combustion chamber 6; The flow rate is large, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com