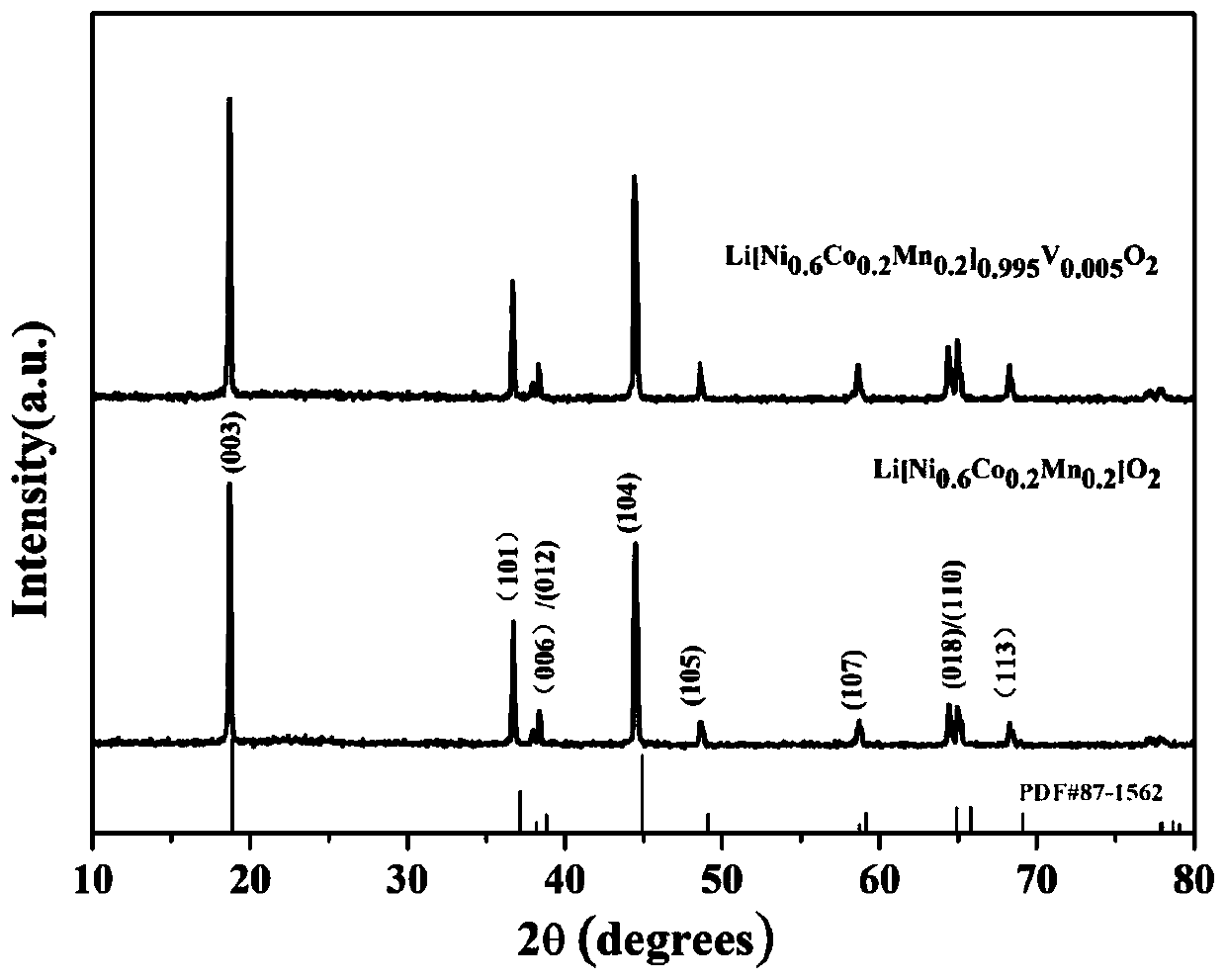

Vanadium-substituted ternary positive electrode material for lithium ion batteries and preparation method thereof

A lithium-ion battery, cathode material technology, applied in battery electrodes, electrical components, secondary batteries, etc., can solve the problems of low gram capacity in the first cycle, poor rate performance, cycle capacity decay, etc., and reduce cation mixing. , Long cycle life, the effect of increasing cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Battery preparation and electrochemical performance testing methods:

[0042] (1) Preparation of battery cathode sheet:

[0043] 0.56g lithium ion cathode material Li[Ni 0.6 co 0.2 mn 0.2 ] 1-x V x o 2 , 0.07g conductive carbon powder, 0.07g polyvinylidene fluoride (PVDF), mix evenly according to the mass ratio of 8:1:1, then add 0.035ml NMP solvent, fully stir to form a viscous slurry, and evenly coat the surface of the aluminum foil , dried by blowing air, placed in a vacuum oven at 120°C for 12 hours, and obtained the positive electrode sheet after rolling for many times.

[0044] (2) Battery assembly and performance testing:

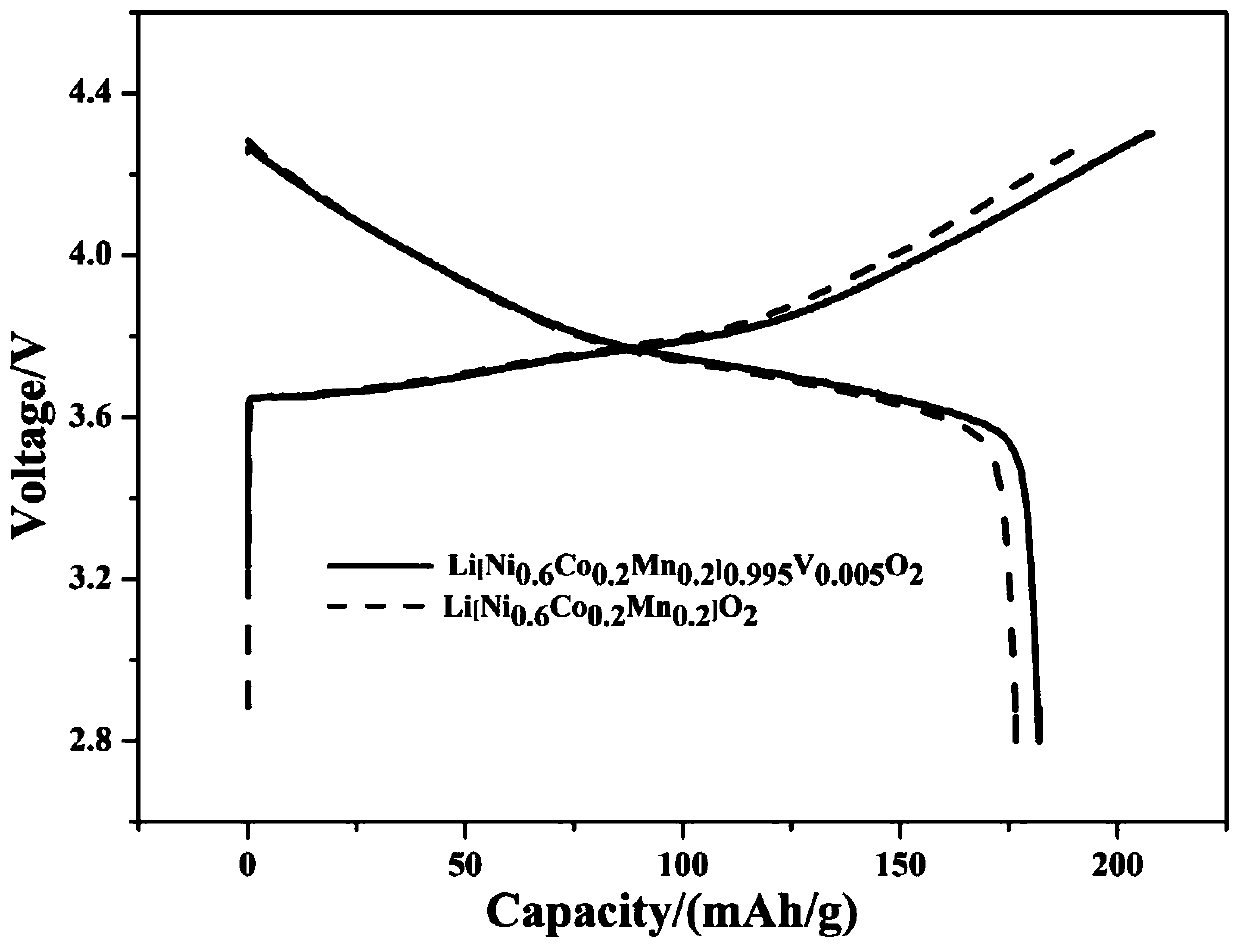

[0045] Obtaining vanadium-substituted LiNi evaluated using 2016-type half-cells 0.6 co 0.2 mn 0.2 o 2 Electrochemical properties of cathode materials. Punch the rolled battery pole piece into a disc with a diameter of 12mm. After accurately weighing its mass, calculate the Li[Ni 0.6 co 0.2 mn 0.2 ] 1-x V x o 2 The quality of ...

Embodiment 1

[0048] A method for preparing a ternary positive electrode material replaced by vanadium for a lithium ion battery, the raw materials used in the preparation process, calculated by mass fraction, include:

[0049] Hydroxygen precursor: 228 parts,

[0050] Lithium hydroxide: 110 parts,

[0051] Vanadium pentoxide: 1.1 parts,

[0052] Its preparation process specifically comprises the following steps:

[0053] 1) Weigh 228 parts by weight of the hydrogen-oxygen precursor Ni 0.6 co 0.2 mn 0.2 (OH) 2 , 110 parts by weight of lithium hydroxide, 1.1 parts by weight of vanadium pentoxide, mixing the powder precursor into a mortar;

[0054] 2) Add 800 parts by weight of alcohol to the powder precursor mixture obtained in step 1), and grind it until it is evenly mixed to obtain a powder precursor mixture;

[0055] 3) Move the powder precursor mixture obtained in step 2) to a tablet press, and press it into a tablet under a pressure of 4MPa;

[0056] 4) move the precursor mixtur...

Embodiment 2

[0061] A method for a ternary positive electrode material replaced by vanadium ions for a lithium ion battery, the raw materials used in the preparation process, calculated by mass fraction, include:

[0062] Hydroxygen precursor: 228 parts

[0063] Lithium hydroxide: 110 parts

[0064] Vanadium pentoxide: 1.1 parts

[0065] Its preparation process specifically comprises the following steps:

[0066] 1) Weigh 228 parts by weight of the hydrogen-oxygen precursor Ni 0.6 co 0.2 mn 0.2 (OH) 2 , the lithium hydroxide of 110 parts by weight, the vanadium pentoxide of 1.1 parts by weight, put the powder precursor mixture into the mortar;

[0067] 2) Add 800 parts by weight of alcohol to the powder precursor mixture obtained in step 1), and grind for 1 to 2 hours until the mixture is evenly mixed to obtain a powder precursor mixture;

[0068] 3) Move the powder precursor mixture obtained in step 2) to a tablet press, and press it into a tablet under a pressure of 4MPa;

[0069] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com