Moth-eye-structure-imitated vanadium dioxide intelligent window film and preparation method thereof

An intelligent and thin film technology of vanadium dioxide, applied in the field of smart windows, can solve the problems of insufficient thermal regulation ability to meet the needs of use, restricting the application in the field of smart windows, and low visible transmission of thin films at low temperature, so as to broaden the scope of application and improve the practicality. the effect of reducing the preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

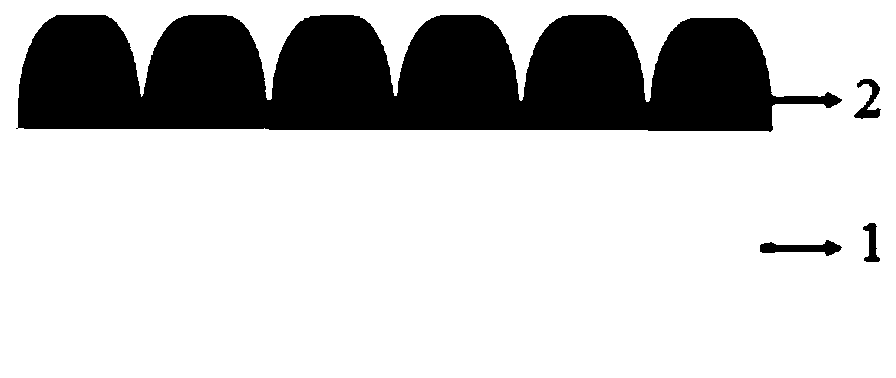

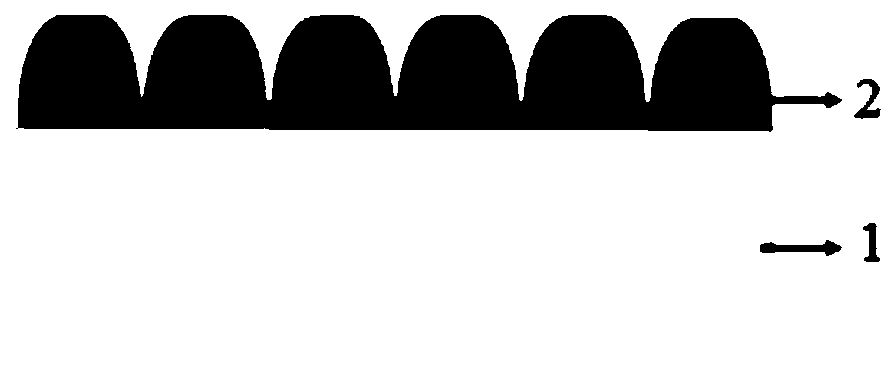

[0021] Specific implementation mode one: combine figure 1 Describe this embodiment in detail. In this embodiment, a vanadium dioxide smart window film with imitation moth-eye structure consists of a base layer and a VO2 film from bottom to top. 2 layer composition;

[0022] The VO 2 layer consists of multiple W-doped VO 2 Composed of micro-nano structural units, and the multiple W-doped VO 2 The micro-nano structural units are evenly distributed on the surface of the upper layer of the base layer, adjacent to the W-doped VO 2 The micro-nano structural units are closely arranged; the W-doped VO 2 The shape of the micro-nano structural unit is conical, cylindrical or truncated; when the W-doped VO 2 When the shape of the micro-nano structural unit is conical, the diameter of the conical bottom surface is 50nm-500nm, and the height is 20nm-300nm; when the W-doped VO 2 When the shape of the micro-nano structural unit is cylindrical, the diameter of the cylindrical shape is 5...

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the base layer is SiO 2 、TiO 2 or polyimide. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific Embodiment 3: The difference between this embodiment and Specific Embodiment 1 or 2 is that the VO 2 The thickness of the layer is 20nm-300nm; the thickness of the base layer is 500μm-1000μm. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com