Method for preparing titanium-tungsten co-doped vanadium dioxide powder from vanadium extraction solution

A vanadium dioxide and co-doping technology, which is applied in the direction of vanadium oxide, etc., can solve the problems of increasing the production cost of vanadium dioxide, being unfavorable for large-scale preparation, and complex preparation processes, etc., achieving excellent sunlight regulation ability, and is beneficial to The effect of wide application and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

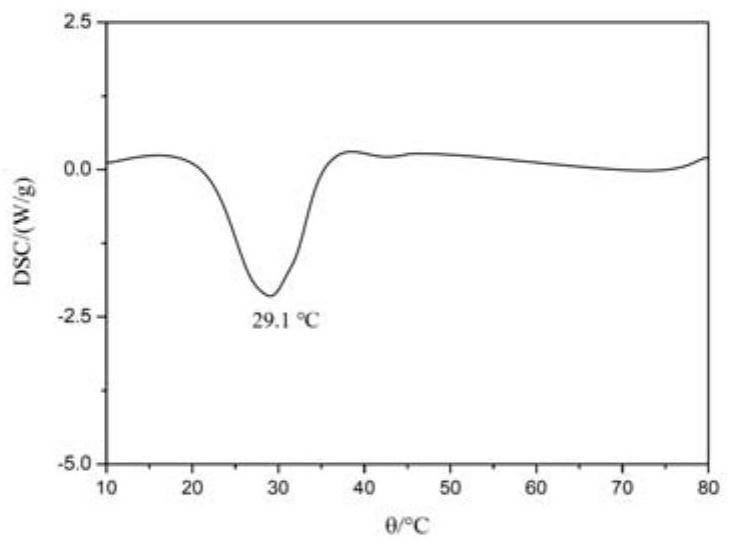

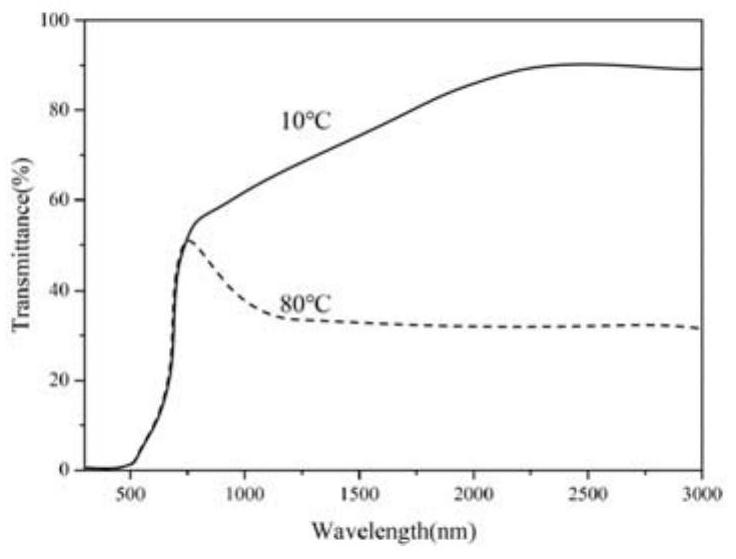

Embodiment 1

[0036]Measure 70mL of vanadium extraction solution, adjust the pH value to 2 with 10% hydrochloric acid solution by mass fraction; measure the concentration of pentavalent vanadium ions by potentiometric titration to 40g / L, that is, the total molar mass of vanadium ions is 0.055mol. Slowly add 4mL hydrazine hydrate (mass fraction is 85%) wherein, promptly the molar weight of reducing agent hydrazine hydrate is 0.068mol, and the molar ratio of vanadium ion and reducing agent is 0.81, and this moment solution turns blue; Add 0.42g of ammonium tungstate and 0.21g of titanium tetrachloride solution to the solution, and use ultrasonic to mix evenly; transfer the mixed solution to a hydrothermal reaction kettle with a volume of 100mL; then, hydrothermally react at 280°C for 15h; after natural cooling , the solution was centrifuged at high speed; then the solid precipitate was washed with ethanol and deionized water; the solid was freeze-dried to obtain 2at% Ti and 3at% W co-doped van...

Embodiment 2

[0043] Measure 70mL of vanadium extraction solution, adjust the pH value to 2 with 10% hydrochloric acid solution by mass fraction; measure the concentration of pentavalent vanadium ions by potentiometric titration to 40g / L, that is, the total molar mass of vanadium ions is 0.055mol. Slowly add 4mL hydrazine hydrate (mass fraction is 85%) wherein, promptly the molar weight of reducing agent hydrazine hydrate is 0.068mol, and the molar ratio of vanadium ion and reducing agent is 0.81, and this moment solution turns blue; Add 0.28g of ammonium tungstate and 0.10g of titanium tetrachloride solution to the solution, and use ultrasonic waves to mix evenly; transfer the mixed solution to a hydrothermal reaction kettle with a volume of 100mL; then conduct a hydrothermal reaction at 280°C for 15h; after natural cooling , the solution was centrifuged at high speed; then the solid precipitate was washed with ethanol and deionized water; the solid was freeze-dried to obtain 1% Ti and 2% W...

Embodiment 3

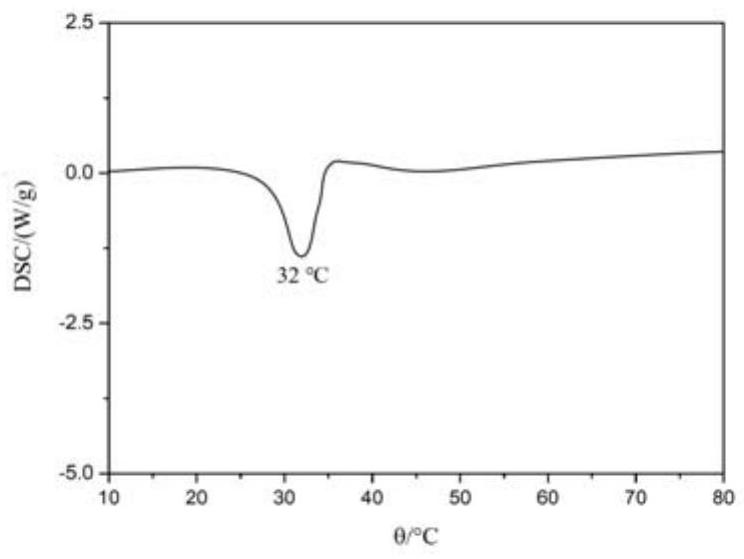

[0049] Measure 70mL of vanadium extraction solution, adjust the pH value to 2 with 10% hydrochloric acid solution by mass fraction; measure the concentration of pentavalent vanadium ions by potentiometric titration to 40g / L, that is, the total molar mass of vanadium ions is 0.055mol. Slowly add 4mL hydrazine hydrate (mass fraction is 85%) wherein, promptly the molar weight of reducing agent hydrazine hydrate is 0.068mol, and the molar ratio of vanadium ion and reducing agent is 0.81, and this moment solution turns blue; Add 0.14g of ammonium tungstate and 0.10g of titanium tetrachloride solution to the solution, and use ultrasonic waves to mix evenly; transfer the mixed solution to a hydrothermal reaction kettle with a volume of 100mL; then conduct a hydrothermal reaction at 280°C for 15h; after natural cooling , the solution is centrifuged at high speed; then the solid precipitate is washed with ethanol and deionized water; the solid is freeze-dried to obtain 1% Ti and 1% W co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com