Cathode material, preparation method of same, and lithium secondary battery

A positive electrode material, lithium pyrophosphate technology, applied in the direction of lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems that affect the commercialization process, low diffusion rate, poor electrochemical performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

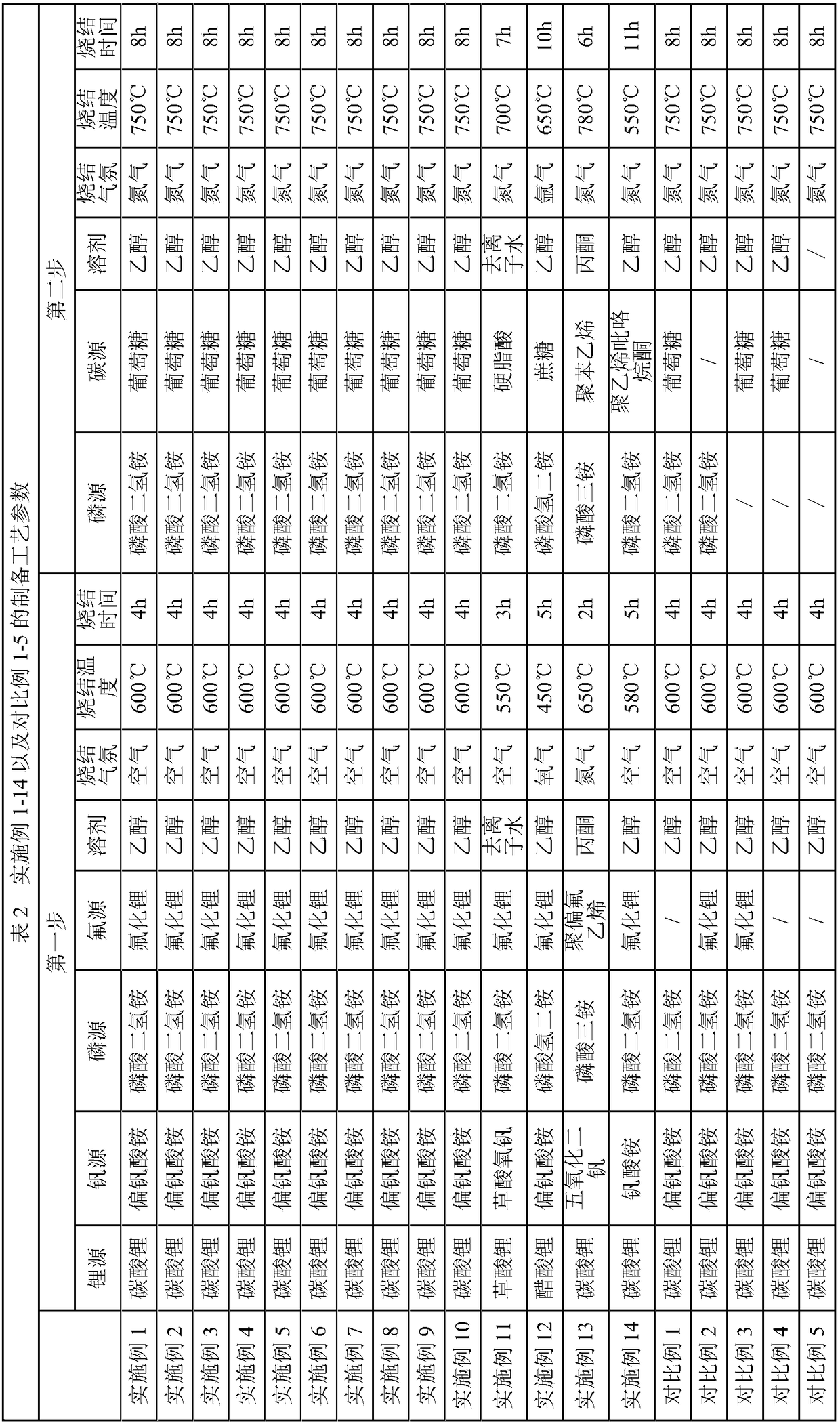

[0020] Next, the preparation method of the positive electrode material according to the second aspect of the present invention is described, which is used to prepare the positive electrode material of the first aspect of the present invention, including the steps: (1) adding excess lithium source, vanadium source, phosphorus source, and fluorine source to the solvent in proportion Mix in a medium to obtain a slurry, dry the slurry and sinter in a non-reducing atmosphere to obtain a precursor with an excess amount of lithium content relative to the target product fluorine-doped lithium vanadyl phosphate; (2) mix the precursor with a phosphorus source and a carbon source according to The ratio is added to a solvent and mixed to obtain a slurry. After the slurry is dried, it is sintered in an inactive atmosphere, so that an intermediate transition layer containing lithium pyrophosphate and a carbon layer surface coating layer are sequentially formed on the surface of the precursor,...

Embodiment 1

[0044] In the first step, the fluorine-doped lithium vanadyl phosphate is LiVO 0.95 f 0.05 PO 4 Excessive lithium source lithium carbonate, vanadium source ammonium metavanadate, phosphorus source ammonium dihydrogen phosphate, fluorine source lithium fluoride in an ethanol solvent according to the atomic molar ratio Li:V:P:F=1.2:1:1:0.05 Mixing is carried out, and then the mixture is transferred to a sand mill for grinding to obtain a slurry, and the slurry is dried and sintered at 600° C. for 4 hours in an air atmosphere to obtain a precursor with excess lithium content.

[0045] In the second step, the precursor obtained in the first step is mixed with the phosphorus source ammonium dihydrogen phosphate and the carbon source glucose in an ethanol solvent at a molar ratio of 1:0.1:0.5 of the precursor, the P atom, and the C atom, and then the The mixture was transferred to a sand mill for grinding to obtain a slurry. After drying the slurry, it was sintered at 750° C. for ...

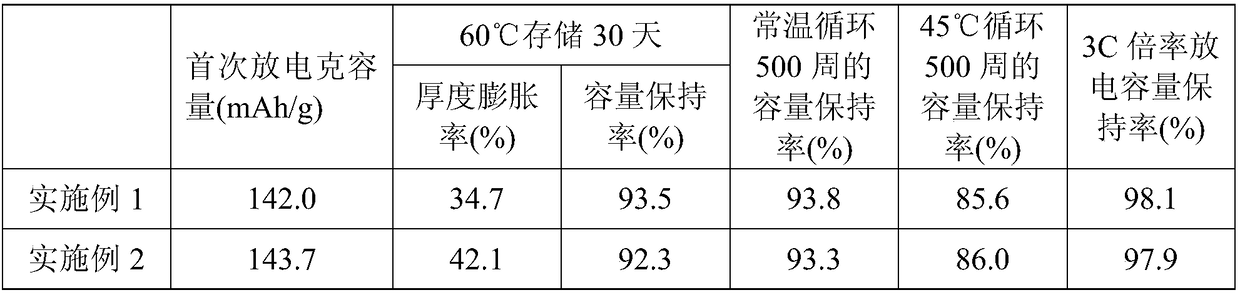

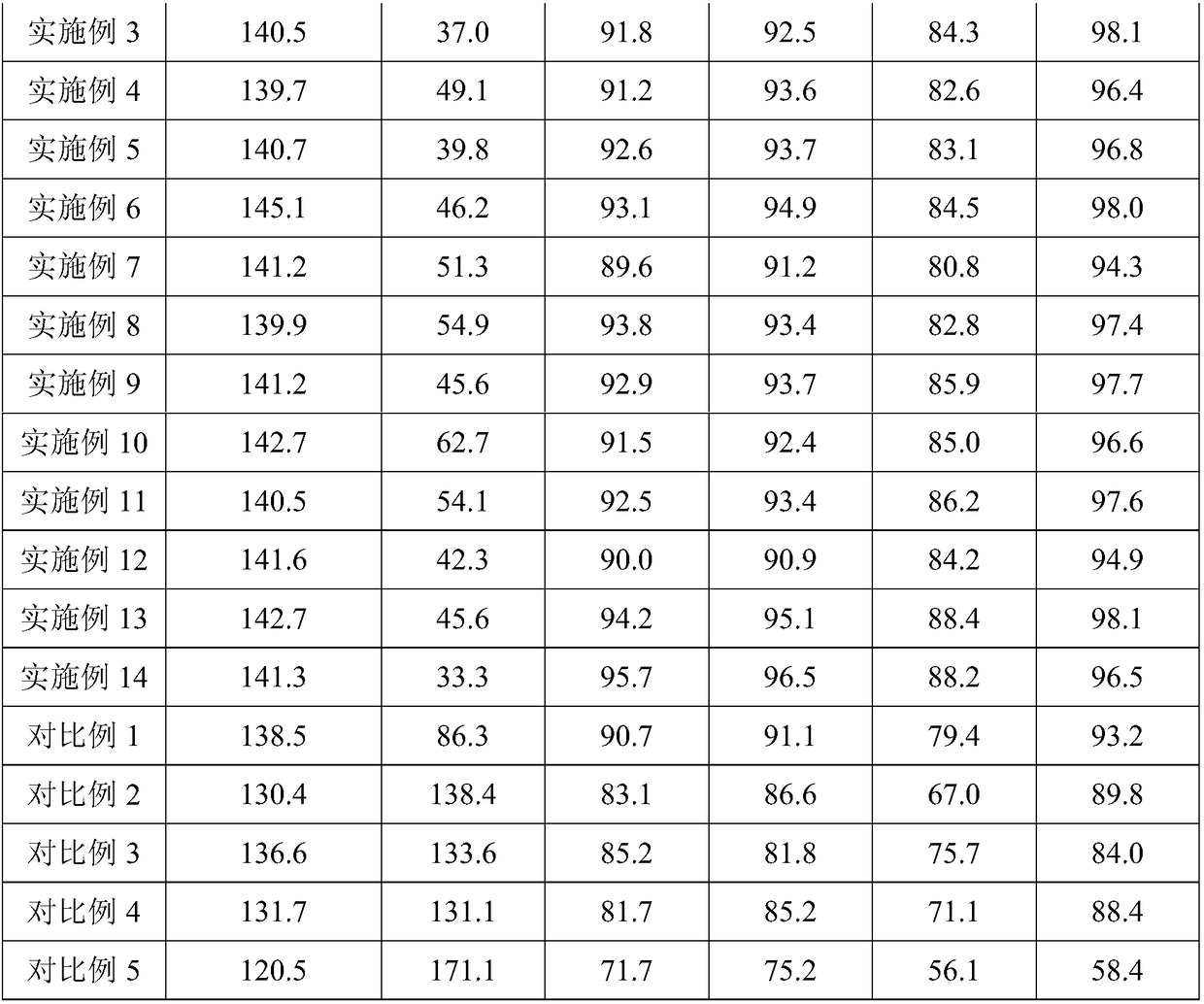

Embodiment 2~14

[0047] The preparation method of the positive electrode materials of Examples 2-14 is the same as that of Example 1. The obtained positive electrode materials and process parameters such as raw material type, solvent type, sintering atmosphere, sintering temperature, and sintering time are shown in Table 1 and Table 2 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com