Method for preparing nano vanadium dioxide by taking pentavalent vanadium alkoxide as raw material

A technology of vanadium dioxide and pentavalent vanadyl alcohol, applied in vanadium oxide, nanotechnology and other directions, can solve the problems of inability to meet particle size requirements, high industry demands, excessive particle size of vanadium dioxide, etc., and achieves easy popularization and application, Controllable process and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

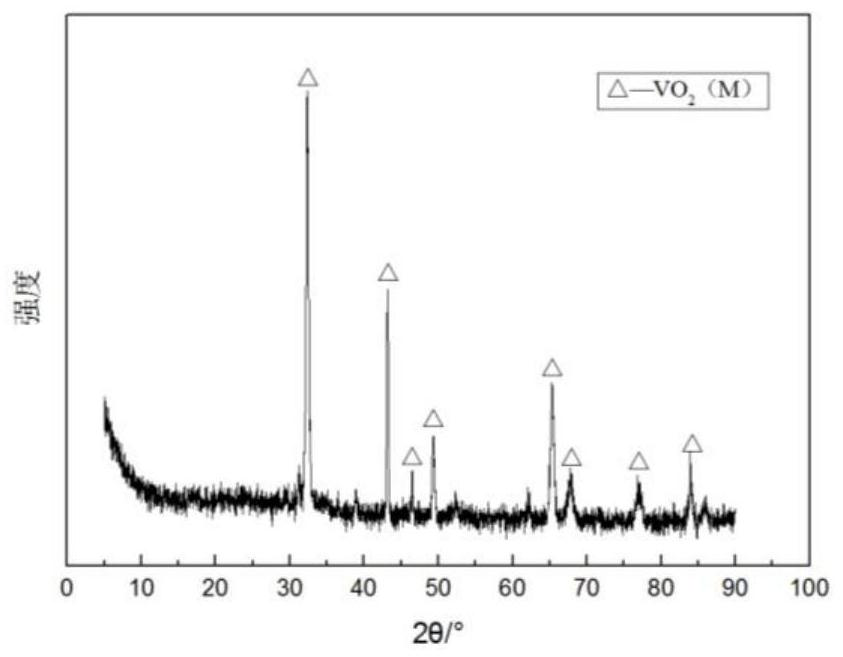

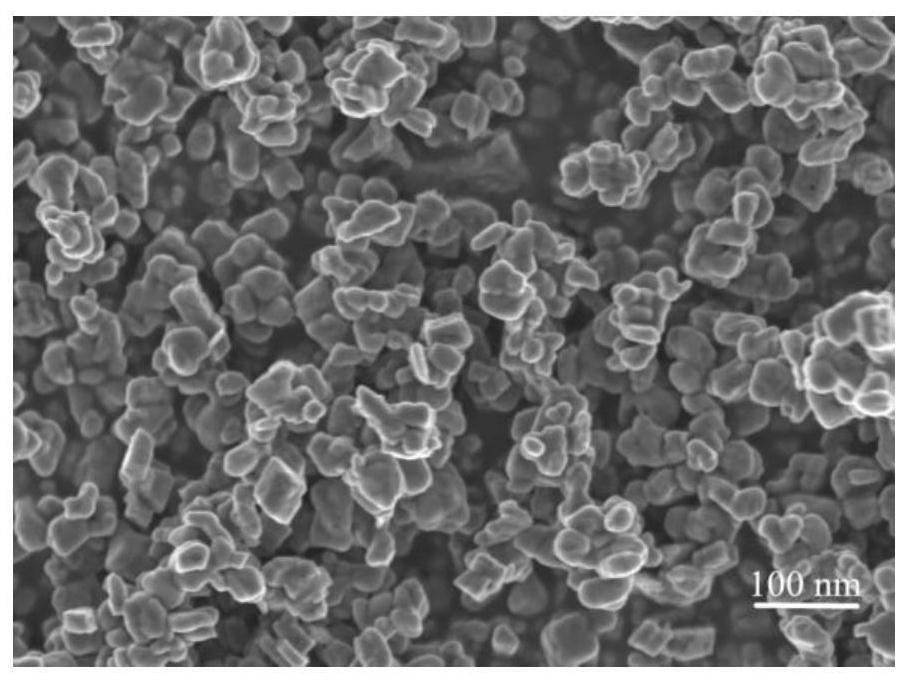

[0031] Stir and mix 70 g of toluene, 0.2 g of vanadyl triisopropoxide, 0.1 g of oleylamine and 2 g of formaldehyde to form a uniform solution. The solution was placed in a reaction kettle lined with polytetrafluoroethylene, and reacted at 180° C. for 2 hours. After the reaction, the product was centrifuged, washed, and dried to obtain a blue-black powder. figure 1 It is the XRD spectrum of the powder, indicating that the crystal form is M phase, figure 2 It is a SEM picture, and it can be seen that the particle size of the product is about 50nm.

Embodiment 2

[0033] Stir and mix 70 g of tetrahydrofuran, 0.4 g of vanadyl triisopropoxide, 0.5 g of oleylamine and 6 g of formic acid to form a uniform solution. The solution was placed in a reaction kettle lined with polytetrafluoroethylene, and reacted at 160° C. for 10 h. After the reaction, the product was centrifuged, washed, and dried to obtain a blue-black powder. Obtain M-phase VO with a particle size of 40-60nm 2 . The particle size is about 50nm.

Embodiment 3

[0035] Stir and mix 70 g of dioxane, 0.5 g of vanadyl triisopropoxide, 0.9 g of oleylamine and 9 g of methylamine to form a uniform solution. The solution was placed in a reaction kettle lined with polytetrafluoroethylene, and reacted at 150° C. for 14 hours. After the reaction, the product was centrifuged, washed, and dried to obtain a blue-black powder. Obtain M-phase VO with a particle size of 40-60nm 2 . The particle size is about 50nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com