Preparation of vanadium-doped sodium niobate piezoelectric catalyst and application of vanadium-doped sodium niobate piezoelectric catalyst in preparation of hydrogen peroxide and hydrogen by catalytic cracking of intermediate water

A catalytic cracking, sodium niobate technology, applied in heterogeneous catalyst chemical elements, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the dangerous, slow oxygen evolution reaction kinetics , reduce water splitting conversion efficiency and other problems, to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Preparation of sodium niobium-doped niobate and application in the preparation of hydrogen peroxide and hydrogen in catalytic cracking of intermediate water

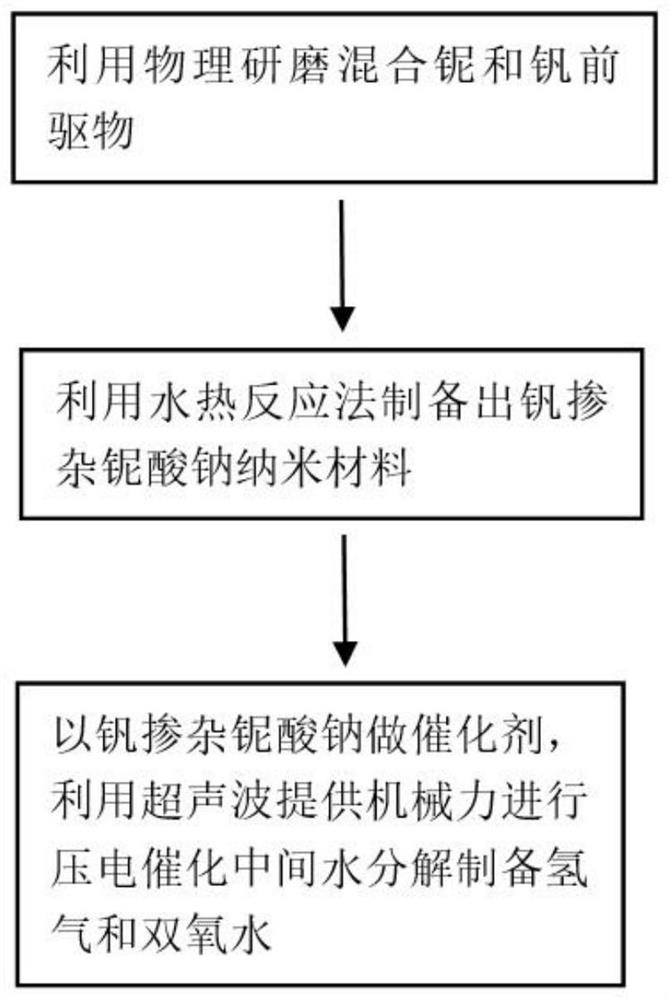

[0029] according to Figure 1 The present embodiment of the process flow diagram comprises the following steps:

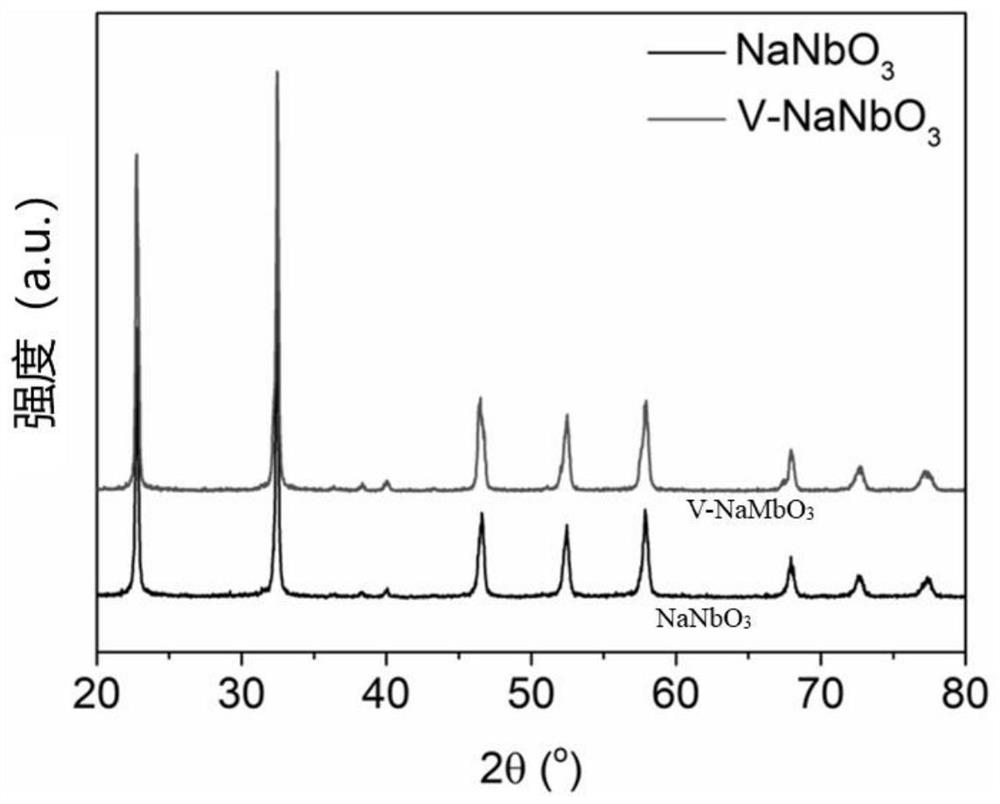

[0030] (1) Preparation of sodium vanadium-doped niobate (V-NaMbO) by hydrothermal method 3): Take 1g niobium oxide and 0.01g vanadium oxide with a mortar grinding and mixing evenly, and then add the mixture to a 40mL sodium hydroxide solution with a concentration of 10M, quickly stir (600r / min) 1h after the mixed mixture is transferred to the high-pressure reactor, and then heated at 180 °C for 18h, after the reaction is completed, the autoclave is cooled to room temperature, the supernatant is removed to obtain a pale yellow precipitate, and the precipitate is repeatedly washed with deionized water for 3-5 times. The resulting pellet was then dried in a vacuum oven at 60 °C to give a pale yellow ...

Embodiment 2

[0036] Example 2 Preparation of sodium niobium-doped niobate and application in the preparation of hydrogen peroxide and hydrogen in catalytic cracking of intermediate water

[0037] according to Figure 1 The present embodiment of the process flow diagram comprises the following steps:

[0038] (1) Preparation of sodium vanadium-doped niobate (V-NaMbO) by hydrothermal method 3 ): Take 1g of niobium oxide and 0.05g of vanadium oxide mixed and grinded, and then under the condition of room temperature stirring, the ground mixture was added to the 40mL sodium hydroxide solution with a concentration of 10M, stirred quickly for 1h and then transferred the mixed mixture to the high-pressure reactor, and then heated at 180 °C for 18h, after the end of the reaction, the high-pressure reactor was cooled to room temperature, the supernatant was removed to obtain a yellowish precipitate, and the precipitate was repeatedly washed with deionized water for 3-5 times. The resulting pellet was the...

Embodiment 3

[0043] Example 3 Preparation of sodium niobium-doped niobate and application in the preparation of hydrogen peroxide and hydrogen in catalytic cracking of intermediate water

[0044] according to Figure 1 The present embodiment of the process flow diagram comprises the following steps:

[0045] (1) Preparation of sodium vanadium-doped niobate (V-NaMbO) by hydrothermal method 3 ): Take 1g niobium oxide and 0.1g vanadium oxide mixed grinding, and then under the condition of room temperature stirring, the ground mixture is added to the 40mL sodium hydroxide solution with a concentration of 10M, quickly stirred for 1h after the mixed mixture is transferred to the high-pressure reactor, and then heated at 180 °C for 18h, after the end of the reaction, the high-pressure reactor is cooled to room temperature, the supernatant is removed to obtain a pale yellow precipitate, the precipitate is repeatedly washed with deionized water for 3-5 times, and then the obtained precipitate is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com