Method for preparing nano vanadium dioxide by reverse hydrolytic precipitation

A technology of hydrolysis precipitation and vanadium dioxide, applied in vanadium oxide, nanotechnology and other directions, can solve the problems of good uniformity, the precursor is not easy to control the dispersibility and uniformity, and it is difficult to obtain the crystallinity, etc., to achieve good crystallinity, Easy to promote and apply in industrialization, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Measure 500ml of sodium hydroxide solution with a concentration range of 300g / L, and add VOSO dropwise to it during rapid stirring 4 When the solution reaches a pH of 7, centrifuge and alternately wash 6 times with deionized water and absolute ethanol, dry the washed solid product at 60°C for 12 hours, and grind to obtain a gray-black powder. Take 0.5g of the powder and add it to 60ml with a volume fraction of 50 % ethanol solution, placed in a high-temperature and high-pressure reactor, hydrothermally reacted at 200 ° C for 24 hours, cooled to room temperature after the reaction was completed, and centrifuged to obtain VO 2 Powder.

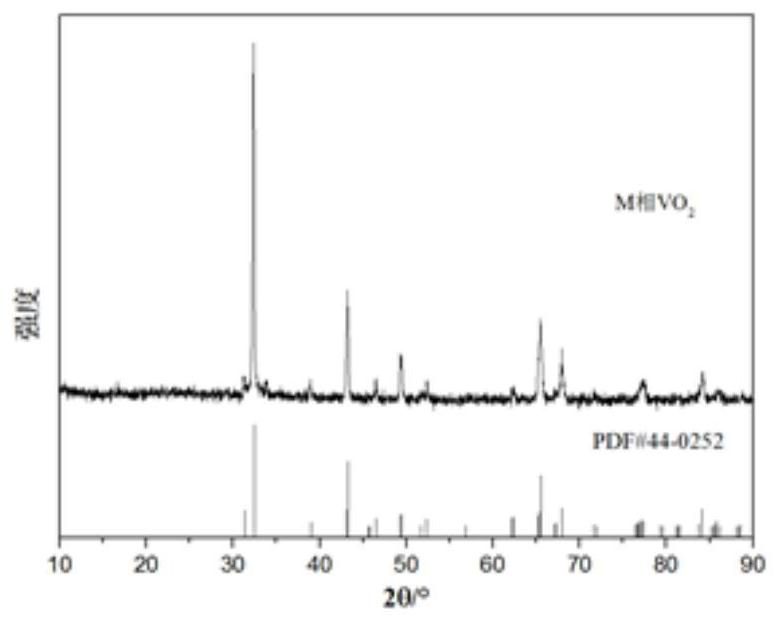

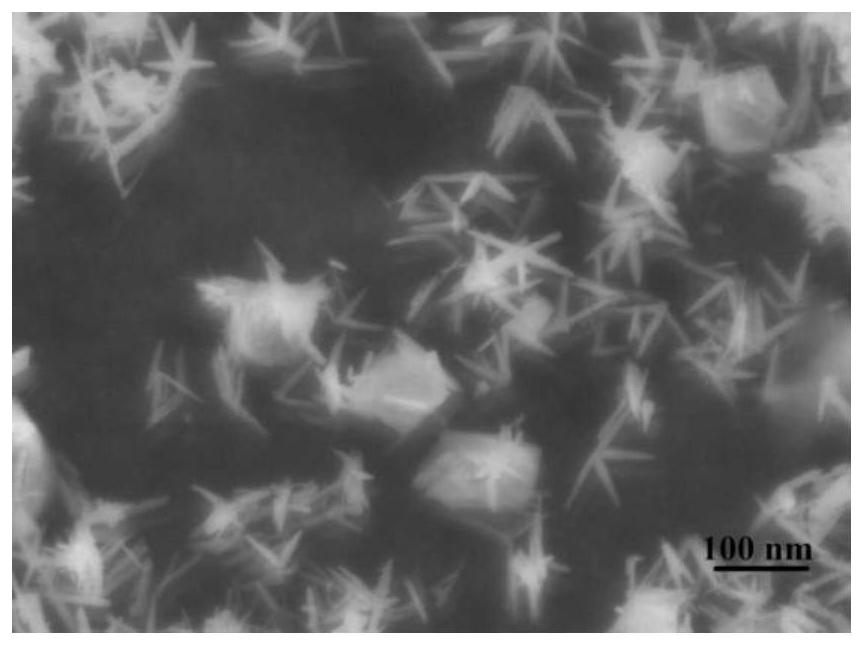

[0029] figure 1 for the VO 2 The XRD spectrum of the powder shows that the product is M phase, figure 2 for the VO 2 SEM image of the powder.

Embodiment 2

[0031] Measure 500ml of sodium hydroxide solution with a concentration range of 450g / L, and add VOSO dropwise to it during rapid stirring 4 When the solution reaches a pH of 8, centrifuge and alternately wash 6 times with deionized water and absolute ethanol, dry the washed solid product at 60°C for 12 hours, and grind to obtain a gray-black powder. Take 3.0 g of the powder and add it to 75 ml with a volume fraction of 50 % ethanol solution, placed in a high-temperature and high-pressure reactor, hydrothermally reacted at 230°C for 18h, cooled to room temperature after the reaction was completed, and centrifuged to obtain VO 2 target product.

Embodiment 3

[0033] Measure 500ml of sodium hydroxide solution with a concentration range of 600g / L, and add VOSO dropwise to it during rapid stirring 4When the solution reaches a pH of 8.5, centrifuge and alternately wash 6 times with deionized water and absolute ethanol, dry the washed solid product at 60°C for 12 hours, and grind to obtain a gray-black powder. Take 5.0 g of the powder and add it to 90 ml with a volume fraction of 50 % ethanol solution, placed in a high-temperature and high-pressure reactor, hydrothermally reacted at 260°C for 12 hours, cooled to room temperature after the reaction was completed, and centrifuged to obtain VO 2 target product.

[0034] As can be seen from the results of the examples, the present invention only adopts the method of reverse precipitation to prepare VO by changing the dropping method of chemical precipitation. 2 , through a large number of repeated experiments, it is determined that the end point of the addition is when the pH value of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com