Preparation method of vanadium dioxide organic composite microcapsule

A composite microcapsule and vanadium dioxide technology, which is applied in the direction of microcapsule preparation and microsphere preparation, can solve the problems that restrict the wide application of vanadium dioxide nanopowder, lose infrared control ability, and be easily oxidized, so as to improve the stability Performance and weather resistance, improved scope of application, and high encapsulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Dissolve 0.1 g vanadium dioxide nanopowder, 0.06 g ascorbic acid, 0.2 mL Tween80, 1 mL glutaraldehyde aqueous solution, 1 mL hydrochloric acid in 4 mL deionized water to form an internal aqueous phase, stir and disperse; dissolve 1.2 mL Span80 in 20 mL An oil phase is formed in n-octane; 0.2 mL Tween80 and 0.1 g wall material PVA-1799 are dissolved in 20 mL deionized water to form an outer water phase.

[0045] Add the inner water phase to the oil phase, shear at 6000 rpm for 40 min to obtain water-in-oil colostrum, add the colostrum dropwise to the outer water phase, raise the temperature to 60 ℃ and continue to stir at 1500 rpm for 5 h, the reaction After completion, the product was centrifuged, washed three times with deionized water and petroleum ether, and dried under vacuum at 45 ℃ to obtain microcapsules with an encapsulation rate of 85.4% and a load rate of 32.2%.

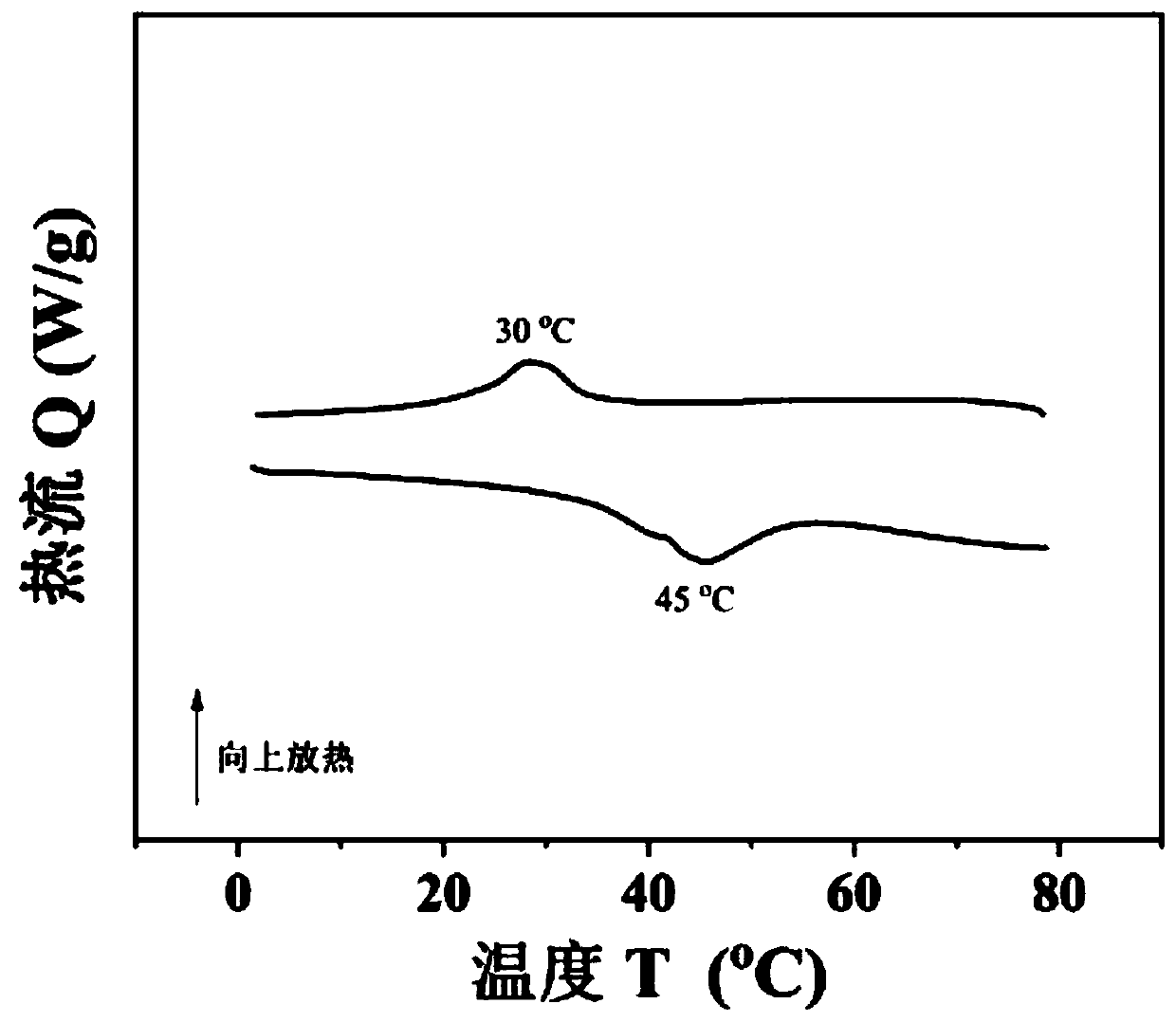

[0046] figure 1 This is the DSC chart of the vanadium dioxide organic composite microcapsules in Examp...

Embodiment 2

[0048] Dissolve 0.1 g vanadium dioxide nanopowder, 0.06 g catechol, 0.2 mL Tween80, 1 mL succinaldehyde aqueous solution, 1 mL acetic acid in 4 mL deionized water to form an internal water phase, stir and disperse; dissolve 1.2 mL Span80 The oil phase was formed in 20 mL cyclohexane; 0.2 mL Tween80, 0.1 g wall material PVA-1788 was dissolved in 20 mL deionized water to form the outer water phase.

[0049] Add the inner water phase to the oil phase, shear at 5000 rpm for 40 min to obtain water-in-oil colostrum, add the colostrum dropwise to the outer water phase, raise the temperature to 60 ℃ and continue stirring at 1000 rpm for 5 h, the reaction After completion, the product was centrifuged, washed three times with deionized water and petroleum ether, and dried in vacuum at 45 ℃ to obtain microcapsules with an encapsulation rate of 81.2% and a load rate of 31.1%.

Embodiment 3

[0051] Dissolve 0.1 g vanadium dioxide nanopowder, 0.06 g polyvinylpyrrolidone, 0.2 mL Tween80, 1 mL malondialdehyde aqueous solution, 1 mL sulfuric acid in 4 mL deionized water to form an internal aqueous phase, stir and disperse; dissolve 1.2 mL Span80 The oil phase was formed in 20 mL n-heptane; 0.2 mL Tween80 and 0.1 g wall material PVA-2088 were dissolved in 20 mL deionized water to form the outer water phase.

[0052] Add the inner water phase to the oil phase, shear at 4000 rpm for 30 min to obtain water-in-oil colostrum, add the colostrum dropwise to the outer water phase, raise the temperature to 60 ℃ and continue stirring at 2000 rpm for 5 h, the reaction After completion, the product was centrifuged, washed three times with deionized water and petroleum ether, and dried in vacuum at 45 ℃ to obtain microcapsules with an encapsulation rate of 83.0% and a load rate of 31.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com