Method for treating oxidized vanadium-nitrogen alloy

A technology of vanadium-nitrogen alloy and nitrogen alloy is applied in the field of treating oxidized vanadium-nitrogen alloy, which can solve the problems of insufficient nitrogen supply in pusher kiln, difficult crushing, long production cycle, etc., so as to increase the reduction effect and shorten the reduction time. , The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for processing vanadium oxide nitrogen alloys, comprising the steps of:

[0040] (1) Mix carbon black: water: sodium silicate at a ratio of 1:0.5:0.01, stir evenly and let stand for 60 minutes to obtain a mixture slurry for later use;

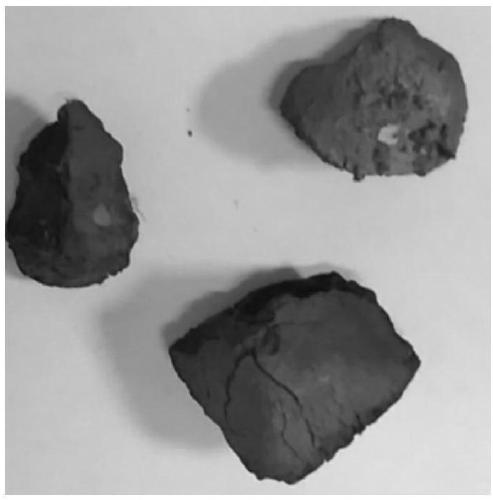

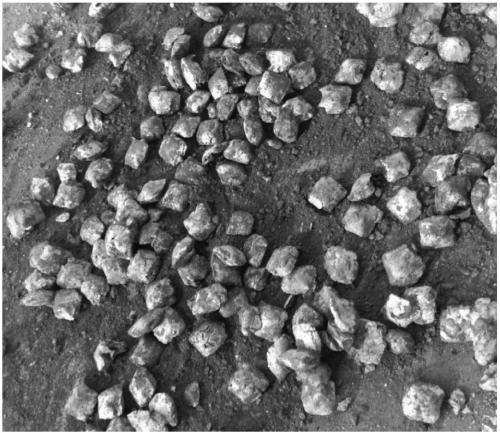

[0041] (2) Put the vanadium-nitrogen alloy whose surface has been oxidized and discolored into the mixture slurry, stir fully to make the mixture slurry fully contact with the surface of the vanadium-nitrogen alloy, put the vanadium-nitrogen alloy taken out on the drying net, let the excess mix The material is controlled to dry and set aside;

[0042] (3) manually kneading the vanadium-nitrogen alloy after drying in step (2), so that the mixture is better combined with the surface of the vanadium-nitrogen alloy to ensure sufficient mixture;

[0043] (4) the vanadium-nitrogen alloy obtained in the step (3) is aired in the air for 3 days in a natural state, the vanadium-nitrogen semi-finished product to be processed is laid in a ...

Embodiment 2

[0045] A method for processing vanadium oxide nitrogen alloys, comprising the steps of:

[0046] (1) Mix carbon black: water: starch in a ratio of 1:1:0.01, stir evenly and let stand for 30 minutes to obtain a mixture slurry for later use;

[0047] (2) Put the vanadium-nitrogen alloy whose surface has been oxidized and discolored into the mixture slurry, stir fully to make the mixture slurry fully contact with the surface of the vanadium-nitrogen alloy, put the vanadium-nitrogen alloy taken out on the drying net, let the excess mix The material is controlled to dry and set aside;

[0048] (3) manually kneading the vanadium-nitrogen alloy after drying in step (2), so that the mixture is better combined with the surface of the vanadium-nitrogen alloy to ensure sufficient mixture;

[0049] (4) the vanadium-nitrogen alloy obtained in the step (3) is aired in the air for 4 days in a natural state, the vanadium-nitrogen semi-finished product to be processed is laid in a crucible, a...

Embodiment 3

[0051] A method for processing vanadium oxide nitrogen alloys, comprising the steps of:

[0052] (1) Mix graphite: water: dextrin in a ratio of 1:0.8:0.01, stir evenly and let stand for 45 minutes to obtain a mixture slurry for later use;

[0053] (2) Put the vanadium-nitrogen alloy whose surface has been oxidized and discolored into the mixture slurry, stir fully to make the mixture slurry fully contact with the surface of the vanadium-nitrogen alloy, put the vanadium-nitrogen alloy taken out on the drying net, let the excess mix The material is controlled to dry and set aside;

[0054] (3) manually kneading the vanadium-nitrogen alloy after drying in step (2), so that the mixture is better combined with the surface of the vanadium-nitrogen alloy to ensure sufficient mixture;

[0055] (4) the vanadium-nitrogen alloy obtained in the step (3) is aired in the air for 5 days in a natural state, the vanadium-nitrogen semi-finished product to be processed is laid in a crucible, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com