Infrared barrier master batch, infrared barrier polyester film and preparation method of infrared barrier polyester film

An infrared blocking and polyester film technology, applied in the field of infrared blocking polyester film and its preparation, and infrared blocking masterbatch, can solve the problems of poor compatibility and uneven dispersion, reduce the phase transition temperature, and enhance the interface bonding force. , the effect of improving the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

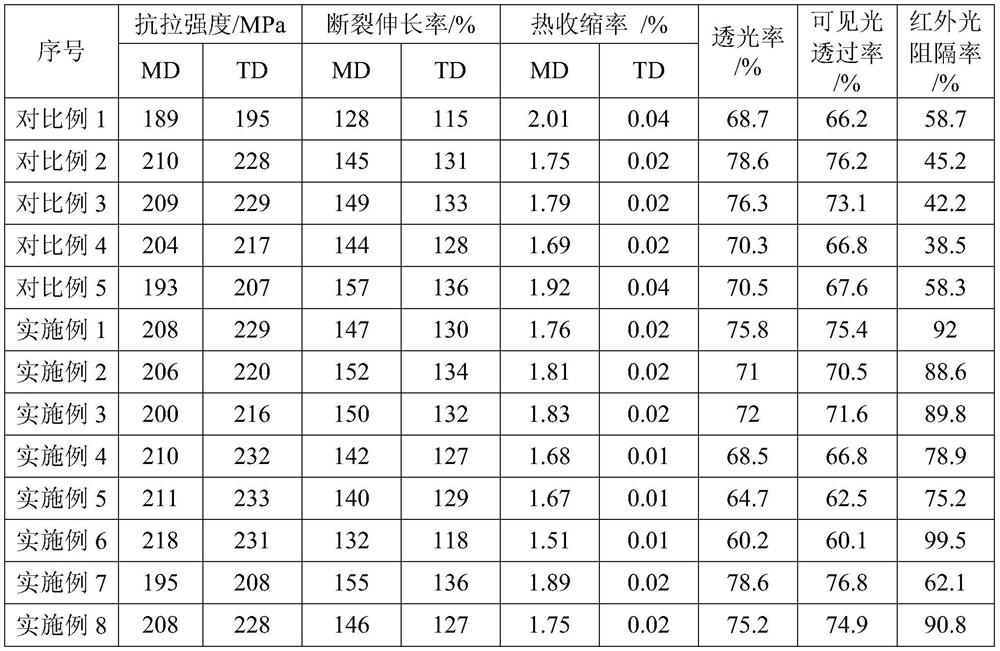

Examples

Embodiment 1

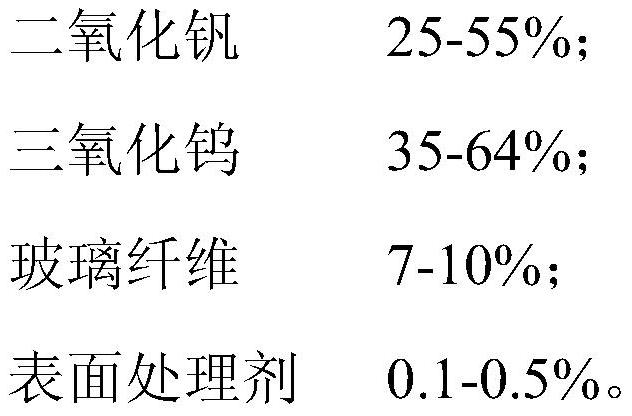

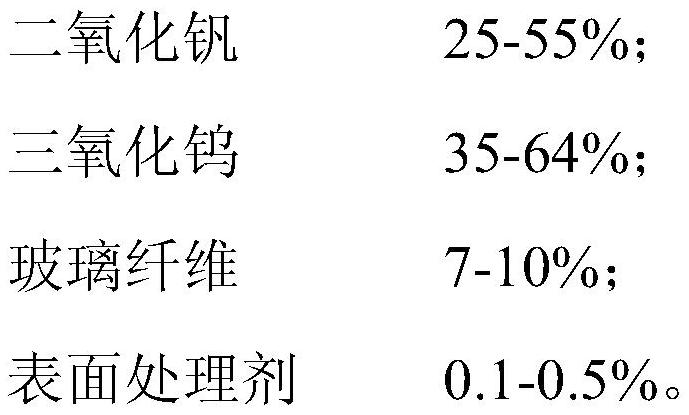

[0056] Preparation of infrared blocking masterbatch:

[0057] (1) Add 0.68kg γ-aminopropyltrimethoxysilane and 0.12kg γ-methacryloxypropyltrimethoxysilane to the mixture of 7.7kg ethanol and 1.5kg water, stir and mix with sodium hydroxide or acetic acid Adjust the pH of the mixture to 6. Add 36kg of vanadium dioxide (doped mass ratio is 2% tungsten, average particle diameter of 160 nanometers), 55kg of tungsten trioxide (average particle diameter of 90 nanometers) and 8.9kg of glass fiber (diameter of 12 microns, length of 120 microns) into the high-speed In the mixer (5000 rev / min), spray 1.25 kg of mist alcohol-water mixture containing surface treatment agent, mix at 60°C for 35 minutes at high speed, then heat up to 115°C and mix at high speed for 100 minutes, and discharge to obtain functional additives.

[0058] (2) Mix 32kg of functional additives and 68kg of polyester evenly, extrude, pelletize, and slice in a co-rotating parallel twin-screw extruder at 275°C±5°C to o...

Embodiment 2

[0062] Preparation of infrared blocking masterbatch:

[0063] (1) Add 0.64kg γ-aminopropyltrimethoxysilane and 0.16kg γ-methacryloxypropyltrimethoxysilane to the mixture of 7.7kg ethanol and 1.5kg water, stir and wash with sodium hydroxide or acetic acid Adjust the pH of the mixture to 6. Add 36kg of vanadium dioxide (doped mass ratio is 2% tungsten, average particle diameter of 160 nanometers), 55kg of tungsten trioxide (average particle diameter of 90 nanometers) and 8.9kg of glass fiber (diameter of 12 microns, length of 120 microns) into the high-speed In the mixer (5000 rev / min), spray 1.25 kg of mist alcohol-water mixture containing surface treatment agent, mix at 60°C for 35 minutes at high speed, then heat up to 115°C and mix at high speed for 100 minutes, and discharge to obtain functional additives.

[0064] Step (2) and the preparation of the infrared-blocking polyester film were the same as in Example 1, and the infrared-blocking polyester film (thickness: 16 mic...

Embodiment 3

[0066] Preparation of infrared blocking masterbatch:

[0067] (1) Add 0.72kg γ-aminopropyltrimethoxysilane and 0.08kg γ-methacryloxypropyltrimethoxysilane to the mixture of 7.7kg ethanol and 1.5kg water, stir and wash with sodium hydroxide or acetic acid Adjust the pH of the mixture to 6. Add 36kg of vanadium dioxide (doped mass ratio is 2% tungsten, average particle diameter of 160 nanometers), 55kg of tungsten trioxide (average particle diameter of 90 nanometers) and 8.9kg of glass fiber (diameter of 12 microns, length of 120 microns) into the high-speed In the mixer (5000 rev / min), spray 1.25 kg of mist alcohol-water mixture containing surface treatment agent, mix at 60°C for 35 minutes at high speed, then heat up to 115°C and mix at high speed for 100 minutes, and discharge to obtain functional additives.

[0068] Step (2) and the preparation of the infrared-blocking polyester film were the same as in Example 1, and the infrared-blocking polyester film (thickness: 16 mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com