Process for synthesizing ZSM-5 molecular sieve

A ZSM-5 and seed crystal technology, applied in the field of synthesizing ZSM-5 molecular sieve, can solve the problems of reducing the production efficiency per unit kettle volume, increasing the production cost of molecular sieve, expensive silica gel, etc. Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The diatomite raw soil is produced in Changbai, Jilin, and it is crushed to a finer than 40 meshes, and its reduction on ignition is 16.6%. The weight percentage composition is shown in Table 1.

[0021] SiO 2

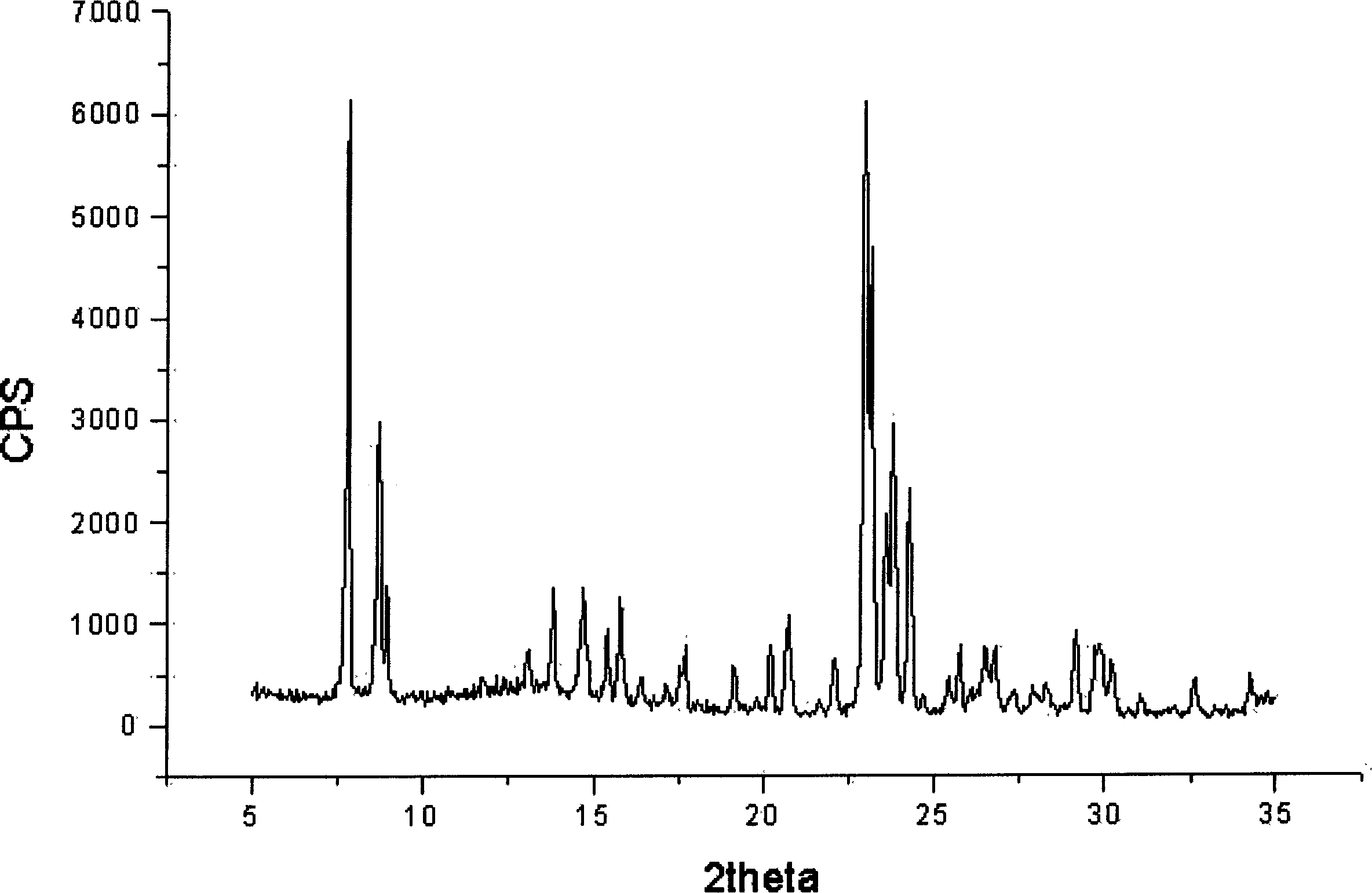

[0022] NaOH, perbasic sodium metaaluminate (composed of Al 2 o 3 =44.4g / l, Na 2 O=291.8g / l), NaY (produced by the Catalyst Factory of Qilu Petrochemical Company) was added into water, and stirred evenly. Add the above-mentioned diatomite raw soil, and configure the mole fraction to be SiO 2 / Al 2 o 3 =40,Na 2 O / SiO 2 =0.1,H 2 O / SiO 2 =10, NaY / diatomaceous earth=0.05 (weight fraction) system, continue stirring. Stir and crystallize in a pressure vessel and raise the temperature to 120°C, keep the temperature constant for 4 hours, then raise the temperature to 180°C, and keep the temperature constant for 16 hours. After cooling, filter, wash, and dry, the X-ray diffraction spectrum of the obtained sample is shown in the accompanying drawing, ...

Embodiment 2

[0024] The raw diatomite in Example 1 was treated with 30% sulfuric acid at 90°C for 6 hours, filtered, washed, and dried. This diatomite is hereinafter referred to as refined soil, and its calcined reduction is 8.2%. The weight percentage composition is shown in the table 2:

[0025] SiO 2

[0026] Other conditions are the same as in Example 1, and the X-ray diffraction spectrum of the obtained sample has the characteristics of the accompanying drawings, which is a ZSM-5 molecular sieve with a crystallinity of 94%.

Embodiment 3

[0028] Add NaOH and perbasic sodium metaaluminate into water and stir well. Add fine soil and configure the mole fraction as SiO 2 / Al 2 o 3 =40,Na 2 O / SiO 2 =0.1,H 2 O / SiO 2 =10 system, continue to stir. Stir and crystallize in a pressure vessel and raise the temperature to 120°C, keep the temperature constant for 4 hours, then raise the temperature to 180°C, and keep the temperature constant for 16 hours. After cooling, filter, wash, and dry, the X-ray diffraction pattern of the obtained sample has the characteristics of the accompanying drawings, which is a ZSM-5 molecular sieve with a crystallinity of 54%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com