Synthetic method of flaky nano-SAPO-34 molecular sieve

A technology of SAPO-34 and molecular sieves, which is applied in the field of preparation of SAPO-34 molecular sieves, can solve problems such as equipment corrosion safety, environmental pollution, and low economic value, and achieve good selectivity, high solid yield, and increased service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation of embodiment 1 sample 1#~sample 10#

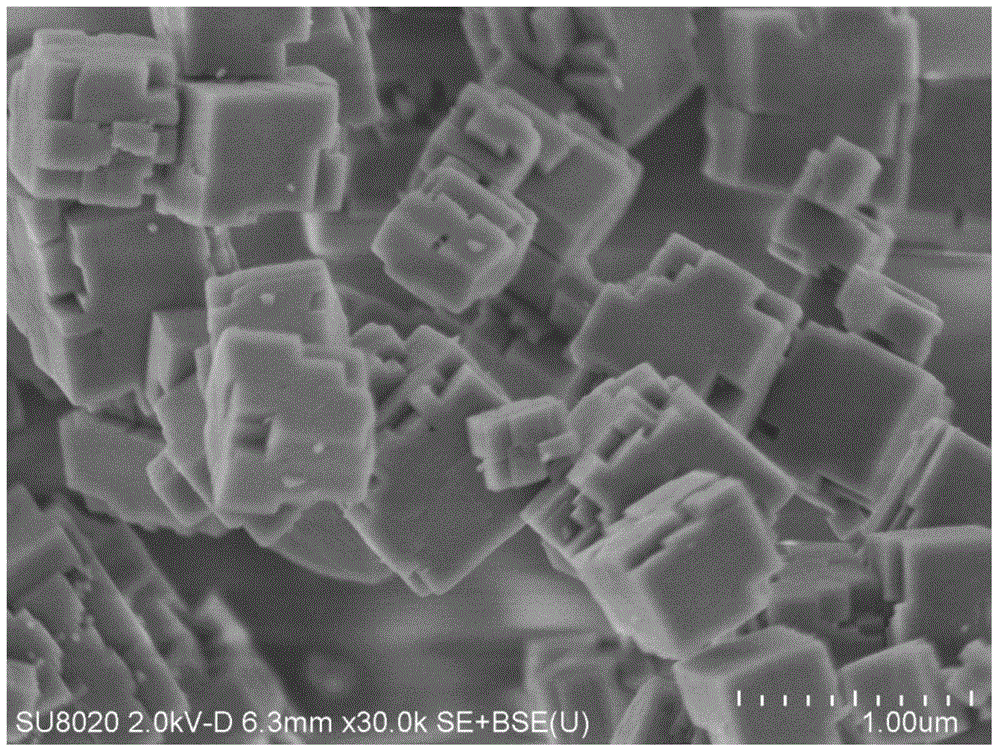

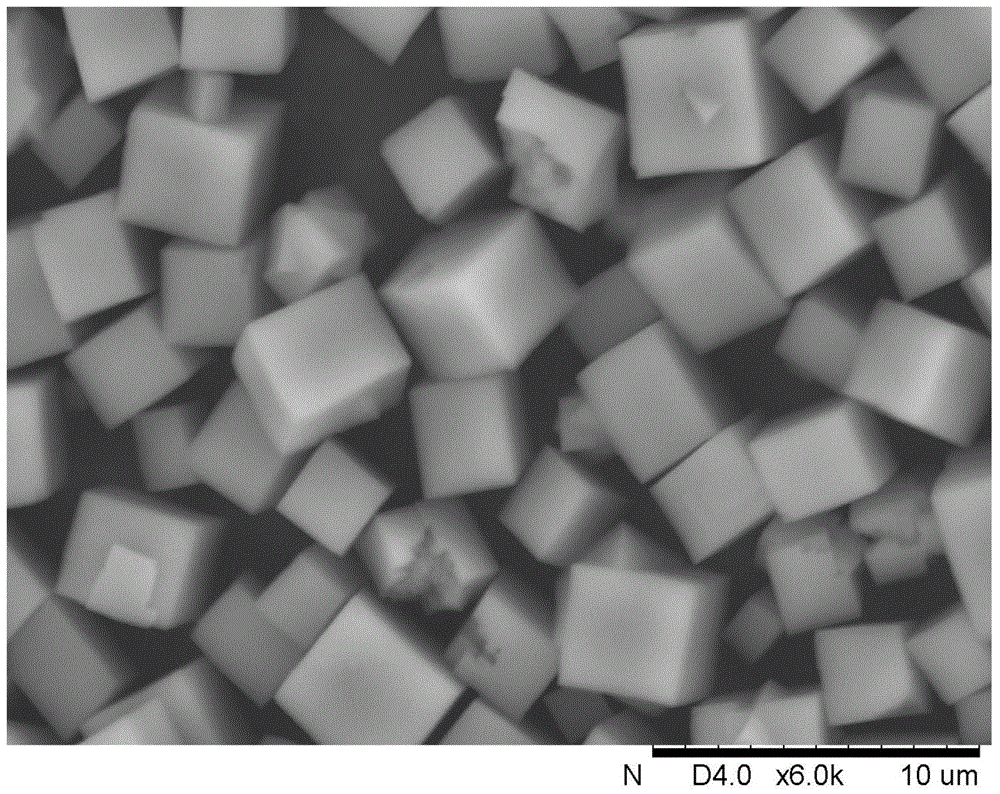

[0044] Preparation of nano SAPO-34 seed crystal: It is synthesized by using WO2003 / 048042 patent method and tetraethylamine hydroxide TEAOH as template agent. The crystal product has a nearly cubic shape and an average particle size of 300nm.

[0045] 9.1g of pseudoboehmite (Al 2 o 3 Content 67.5wt%) mixed with 52.3g deionized water, after stirring evenly, in this mixed solution, dropwise add 13.8g phosphoric acid (85wt%), continue to stir until forming uniform white gel, add 4.0g alkaline silica sol ( 31wt%), stirred evenly, finally added 12.1g triethylamine, fully stirred and added 0.45g ethylene glycol, to obtain the initial gel of synthetic SAPO-34 molecular sieve. Add seed crystals equivalent to 12% of the dry weight of the gel to the initial gel, stir evenly, transfer to a stainless steel autoclave, age at 100°C for 6 hours, and then heat up to 200°C for dynamic crystallization for 24 hours. After the cryst...

Embodiment 2

[0055] Embodiment 2XRD and SEM characterizing result

[0056] XRD analysis was carried out on samples 1# to 10# in Example 1, with sample 1# as a typical representative, and the XRD data results are shown in Table 2. The XRD data results of samples 2# to 10# are close to those in Table 2, that is, the peak positions and shapes are the same, and the relative peak intensity of the peaks fluctuates in the range of ±10% according to the change of synthesis conditions, indicating that the synthesized products have the characteristics of SAPO-34 structure .

[0057] XRD result of table 2 sample 1#

[0058]

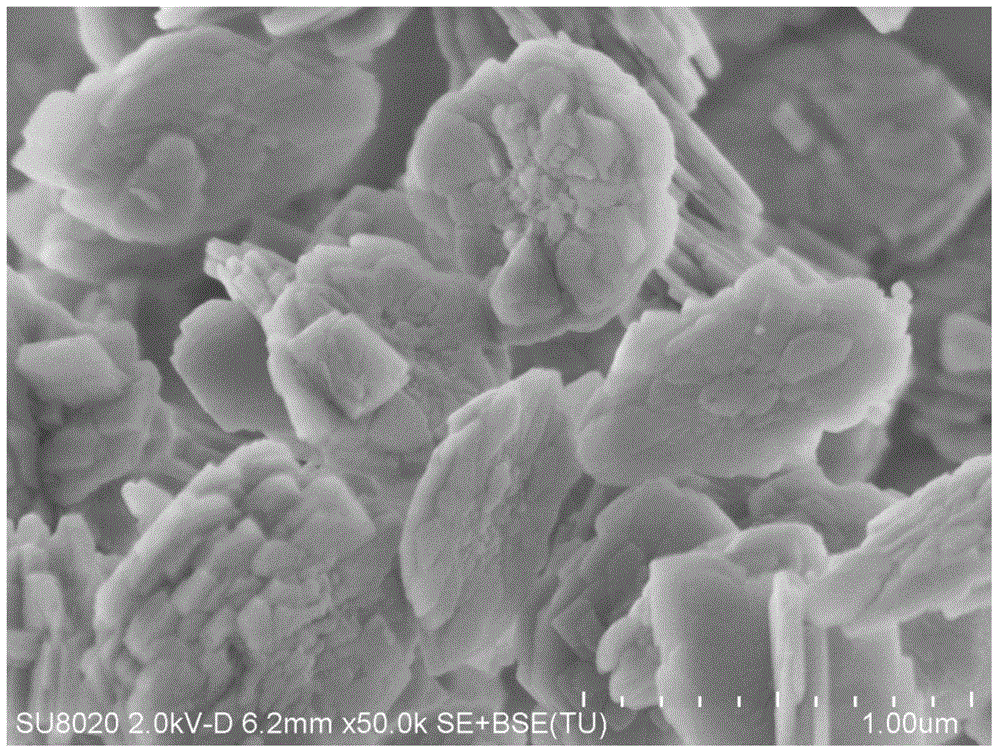

[0059] The morphology of sample 1# to sample 10# and comparative sample 1# to comparative sample 3# in Example 1 was analyzed by scanning electron microscope. The results show that samples 1# to 10# all have lamellar morphology, the thickness of a single sheet is 50-200nm, and the surface of the sheet is not smooth and has a flower-like structure, and the size of the sheet ...

Embodiment 3

[0062] Example 3 Methanol Conversion to Olefin Reaction Performance Test

[0063] The reaction performance of methanol conversion to olefins was tested for sample 1#, comparative sample 1# and comparative sample 2# respectively.

[0064] Sample 1#, comparative sample 1# and comparative sample 2# were roasted at 550°C for 4 hours, and then pressed into tablets and crushed to 20-40 mesh. Weigh 1.0g sample and load it into a fixed-bed reactor for MTO reaction evaluation. Activate at 550°C with nitrogen for 1 hour, then lower the temperature to the reaction temperature of 450°C. Close the nitrogen, feed the methanol aqueous solution of 40wt% concentration with a plunger pump, and the methanol weight space velocity is 4.0h -1 . The reaction product was analyzed by online gas chromatography (Varian3800, FID detector, capillary column PoraPLOTQ-HT), and the results are shown in Table 3. It can be seen that the sample prepared according to the method of the present application is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com