Synthesis method of titanium-containing molecular sieve

A synthesis method and molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve problems such as cyclic molecular amines that have not yet been seen, and achieve reduced production costs, good repeatability, and pollution. The effect of low emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The first step is the synthesis of directing agent

[0030] The molar ratio of SiO2 in tetraethyl silicate: tetrapropyl ammonium hydroxide: TiO2 in tetrabutyl titanate: H2O is 1: 0.1: 0.04: 20, and the reaction mixture is prepared and hydrolyzed at 60°C to form a gel 0.5-1 hour, then raise the temperature to 80°C, and chase the alcohol for 4 hours to prepare the directing agent;

[0031] Preparation of the second step reaction mixture

[0032] The silicon source is silica gel, the titanium source is tetrabutyl titanate, the template agent is hexamethyleneimine, and the SiO in the silicon source is molar ratio 2 : Organic base template: TiO in titanium source 2 :H 2 O is 1:1:0.033:12 to prepare the mixture solution, add SiO in the silicon source 2 The directing agent that the last step of 3% of weight makes, forms reaction mixture;

[0033] The third step hydrothermal crystallization

[0034] Hydrothermal crystallization at 170°C for 4 days to obtain TS-1 molecular...

Embodiment 2

[0037] Implementation process is except following difference, and all the other are all the same with embodiment 1:

[0038] The first step is the synthesis of directing agent

[0039] Molar ratio of SiO in silicon source 2 : Organic base template: TiO in titanium source 2 :H 2 O is 1:0.2:0.1:80;

[0040] Preparation of the second step reaction mixture

[0041] The organic template is a mixture of hexamethyleneimine and piperidine, and the molar ratio of the two is 5:5.

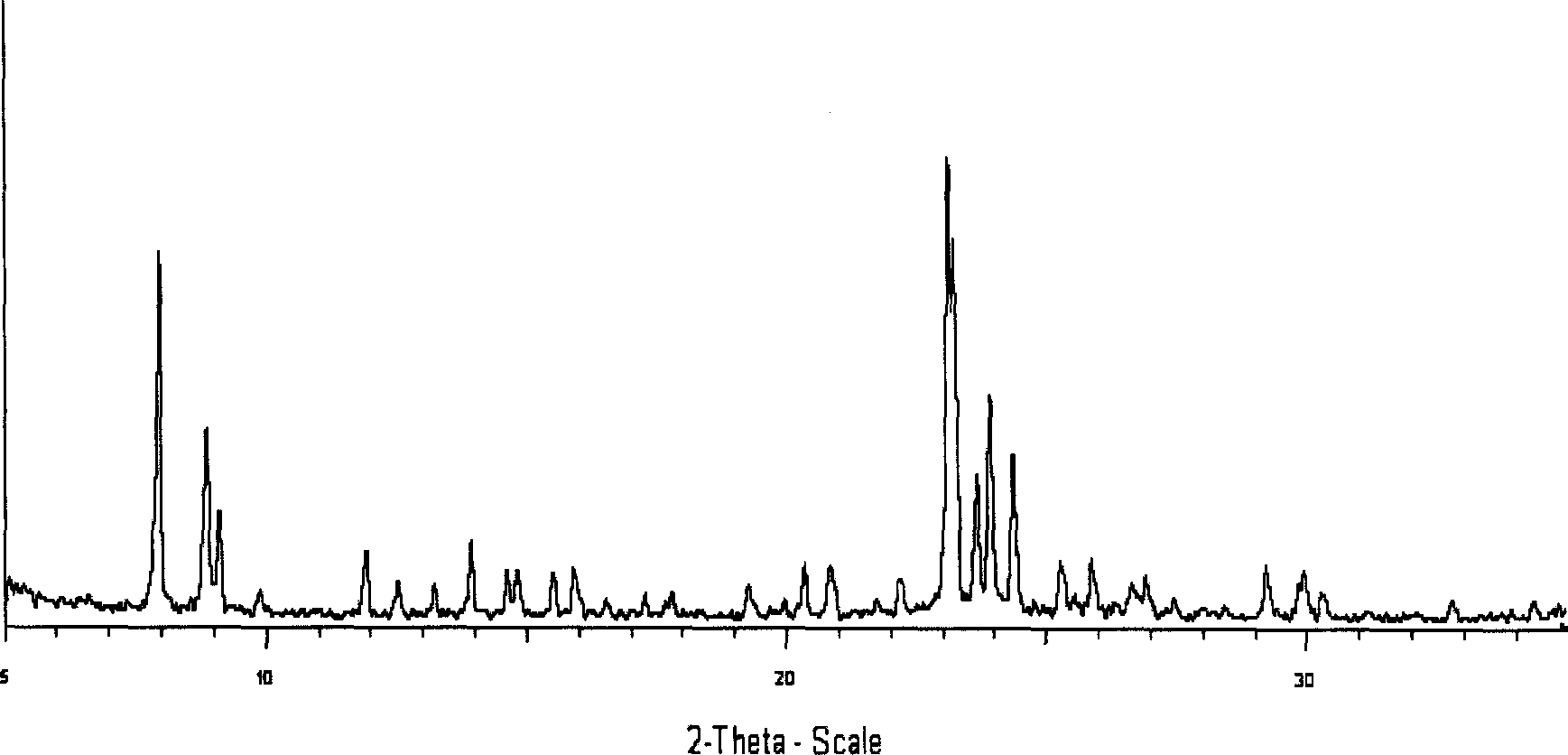

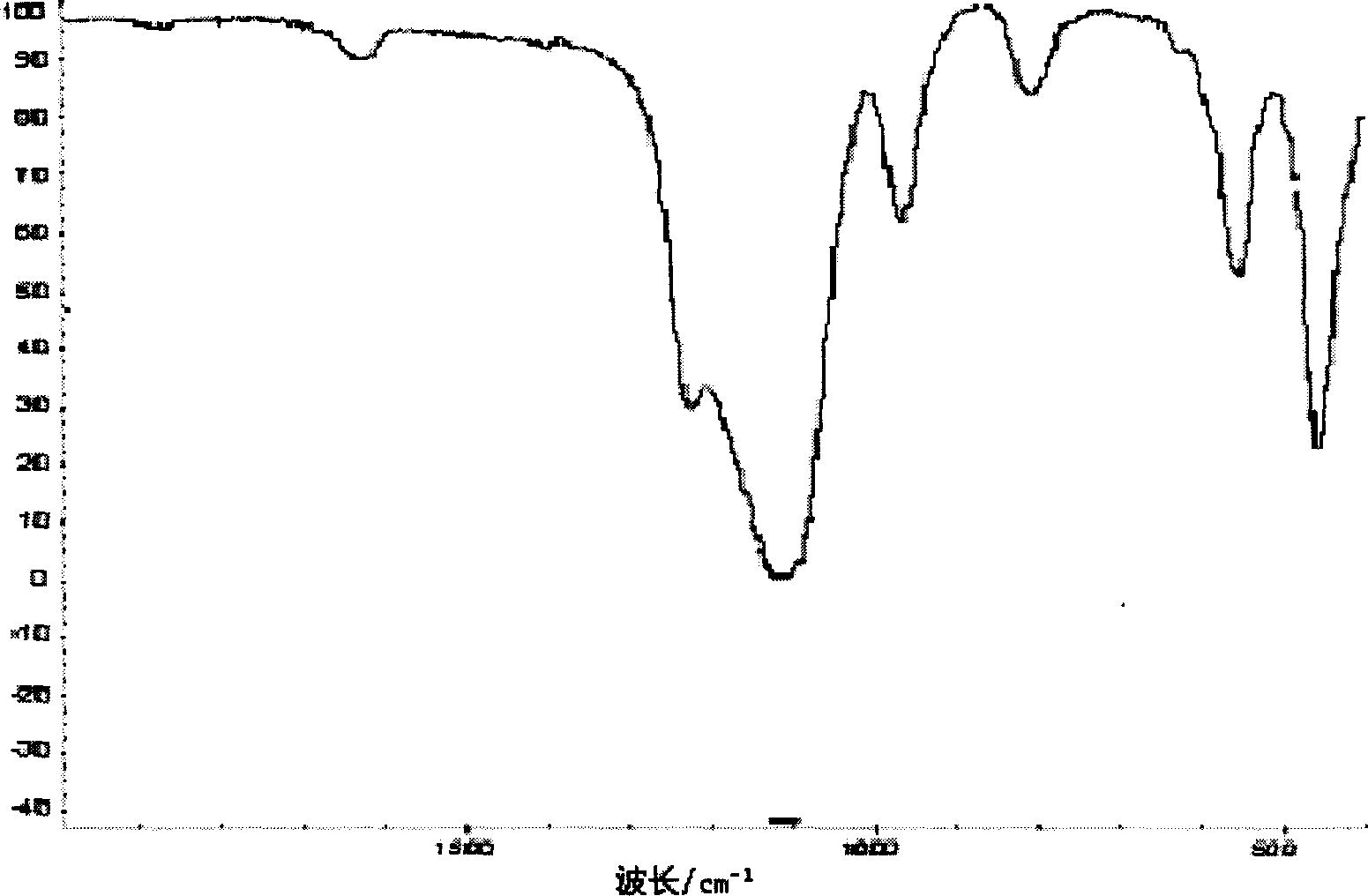

[0042] XRD spectrum of TS-1 molecular sieve and figure 1 Similarly, the IR spectrum with figure 2 similar.

Embodiment 3

[0044] Implementation process is except following difference, and all the other are all the same with embodiment 1:

[0045] Preparation of the second step reaction mixture

[0046] The organic template is piperidine, adding SiO based on silicon source 2 15% by weight of the directing agent prepared in the previous step to form a reaction mixture.

[0047] XRD spectrum of TS-1 molecular sieve and figure 1 Similarly, the IR spectrum with figure 2 similar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com