Adhesive used for high-heat resistance leadless low-dielectric copper-clad plate and preparation method thereof

A copper-clad laminate and low-dielectric technology, which is applied in the adhesive and preparation field of high heat-resistant lead-free low-dielectric copper-clad laminate, can solve the problem of long curing time, high curing temperature, and high material cost. problems, to achieve the effect of improving dielectric properties and heat and humidity resistance, high heat resistance and chemical resistance, and reducing hydroxyl content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1~3

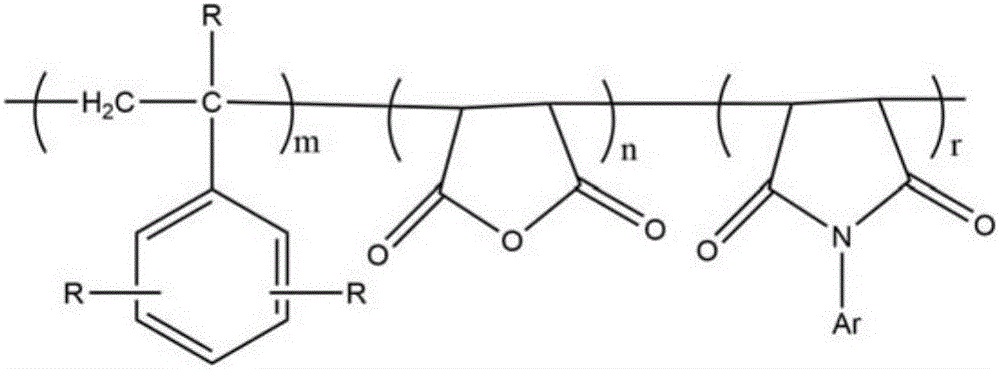

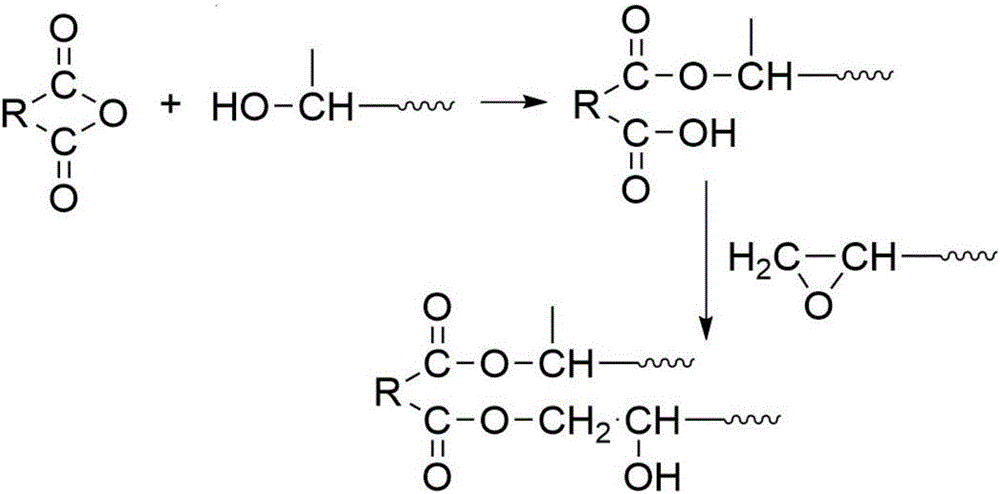

[0053] An adhesive suitable for high heat resistance lead-free low dielectric copper clad laminates. The main raw materials are low dielectric epoxy resin, modified polymeric anhydride curing agent, cyanate ester curing agent and active ester curing agent. Agents, brominated flame retardants, inorganic fillers, organic solvents and toughening agents.

[0054] material name Example 1 Example 2 Example 3 Comparative example 1 Comparative example 2 Comparative example 3 Low Dielectric Epoxy 18 17 19 18 21 20 Modified polymeric anhydride 15 16 17 18 16 ---- Cyanate Curing Agent 12 13 12 12 ---- 16 Active ester curing agent 3 4 2 ---- 12 12 Brominated Flame Retardants 16 16 16 16 16 16 Silane 0.18 0.15 0.15 0.18 0.15 0.16 metal curing accelerator 0.02 0.02 0.02 0.01 ---- 0.02 Amine Accelerator 0.02 0.01 0.01 ---- 0.02 0.02 imidazole accelerator 0.01 0.01 0.01 0.01 0...

Embodiment 4

[0077] The adhesive for high heat-resistant lead-free low-dielectric copper-clad laminates is prepared from the following components and raw materials in parts by weight:

[0078] Low dielectric epoxy resin 70, modified polymeric anhydride 40, cyanate ester curing agent 40, active ester curing agent 40, brominated flame retardant 50, silane 1, metal curing accelerator 0.1, amine accelerator 0.1, imidazole accelerator 0.1, inorganic filler 60, toughening agent 8.

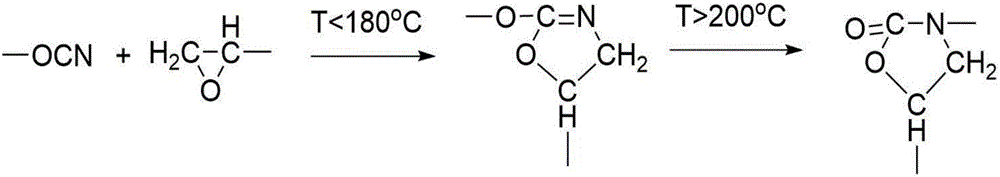

[0079] The low-dielectric epoxy resin used is a mixture of biphenyl epoxy resin and naphthalene ring epoxy resin, and the modified polymeric anhydride is a terpolymer formed by modifying styrene-maleic anhydride copolymer with aromatic amine compounds , The weight average molecular weight is 2000, the cyanate ester curing agent is a bisphenol type cyanate ester curing agent, the weight average molecular weight is 500, and the active ester curing agent is selected from active ester curing agents containing naphthalene...

Embodiment 5

[0085] The adhesive for high heat-resistant lead-free low-dielectric copper-clad laminates is prepared from the following components and raw materials in parts by weight:

[0086] Low dielectric epoxy resin 20, modified polymeric anhydride 15, cyanate ester curing agent 5, active ester curing agent 5, bromine-containing flame retardant 10, silane 0.05, metal curing accelerator 0.001, amine accelerator 0.001, imidazole accelerator 0.005, inorganic filler 10, toughening agent 1.

[0087] The low-dielectric epoxy resin used is naphthylene ether type epoxy resin, the modified polymeric anhydride is XQR-147 resin produced by Dow Chemical in the United States, and the cyanate-based curing agent is bis(4-cyanate- 3,5-dimethylphenyl) methane, weight average molecular weight 700, active ester curing agent is active ester containing dicyclopentadiene biphenol structure. The metal-based curing accelerator is zinc acetylacetonate iron octoate, the amine-based accelerator is 2,4,6-tris(di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com