Resin composition for high-frequency high-speed substrate as well as prepreg and laminated board made of resin composition

The technology of resin composition and prepreg is applied in the fields of electronic materials and communication printed circuit boards, which can solve the problems of insufficient adhesion between substrates and copper foils, functional failure of printed circuit boards, and poor moisture and heat resistance of laminates. Achieve the effect of increasing glass transition temperature, improving heat resistance, and good heat and humidity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

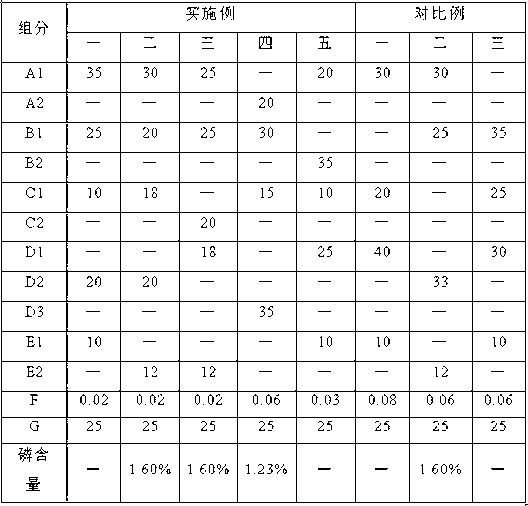

[0035] Embodiment: A kind of resin composition for high-frequency high-speed substrate, by solid weight, comprises the following components, see the table below:

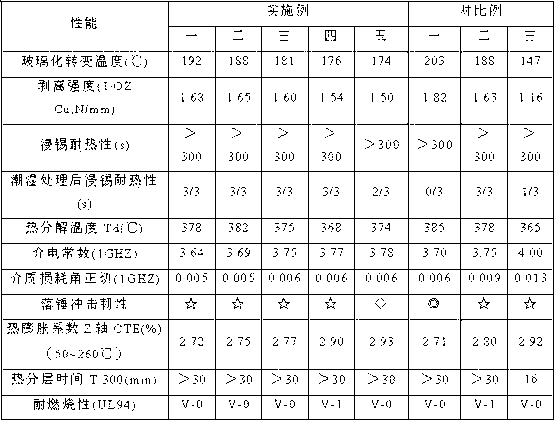

[0036] Table 1 Composition formula

[0037]

[0038] In the above table, A component represents cyanate ester resin monomer or its prepolymer, B component represents acid anhydride compound, C component represents benzoxazine resin, D component represents epoxy resin, E component represents resistance Combustion agent, F component means curing accelerator, G component means inorganic filler.

[0039] Cyanate resin

[0040] A1: bisphenol A cyanate resin;

[0041] A2: bisphenol F cyanate resin;

[0042] Anhydride compound

[0043] B1: Styrene maleic anhydride compound;

[0044]B2: 3,3',4,4'-biphenyltetracarboxylic dianhydride compound;

[0045] Benzoxazine resin

[0046] C1: bisphenol A benzoxazine resin;

[0047] C2: bisphenol F type benzoxazine resin;

[0048] epoxy resin

[0049] D1: biphenyl type epox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com