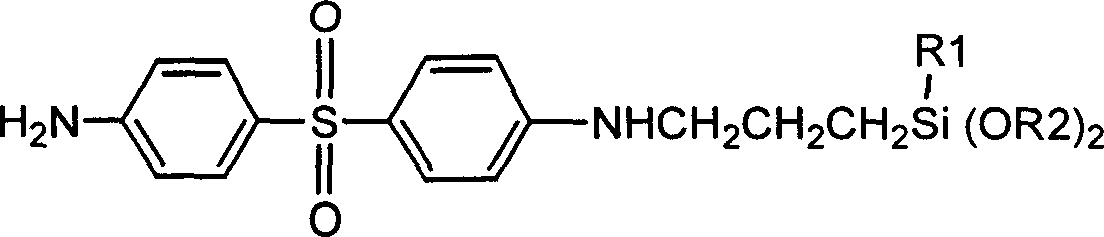

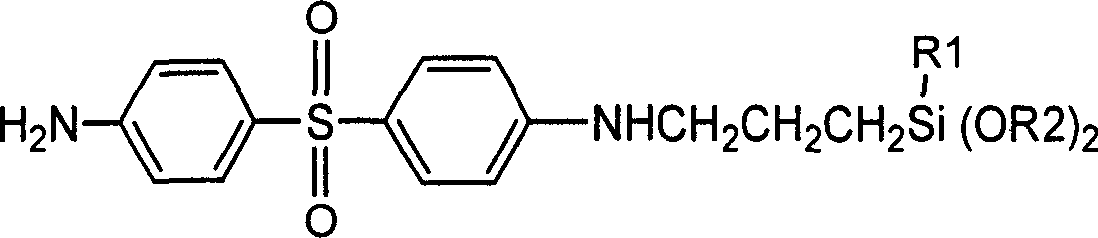

Diphenyl sulfone-containing aminosilane coupling agent and preparing method thereof

A technology of aminosilane coupling agent and diphenylsulfone, which is applied in the field of diphenylsulfone-containing aminosilane coupling agent and its preparation, and can solve the problems of inability to improve the dielectric properties of composite materials and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

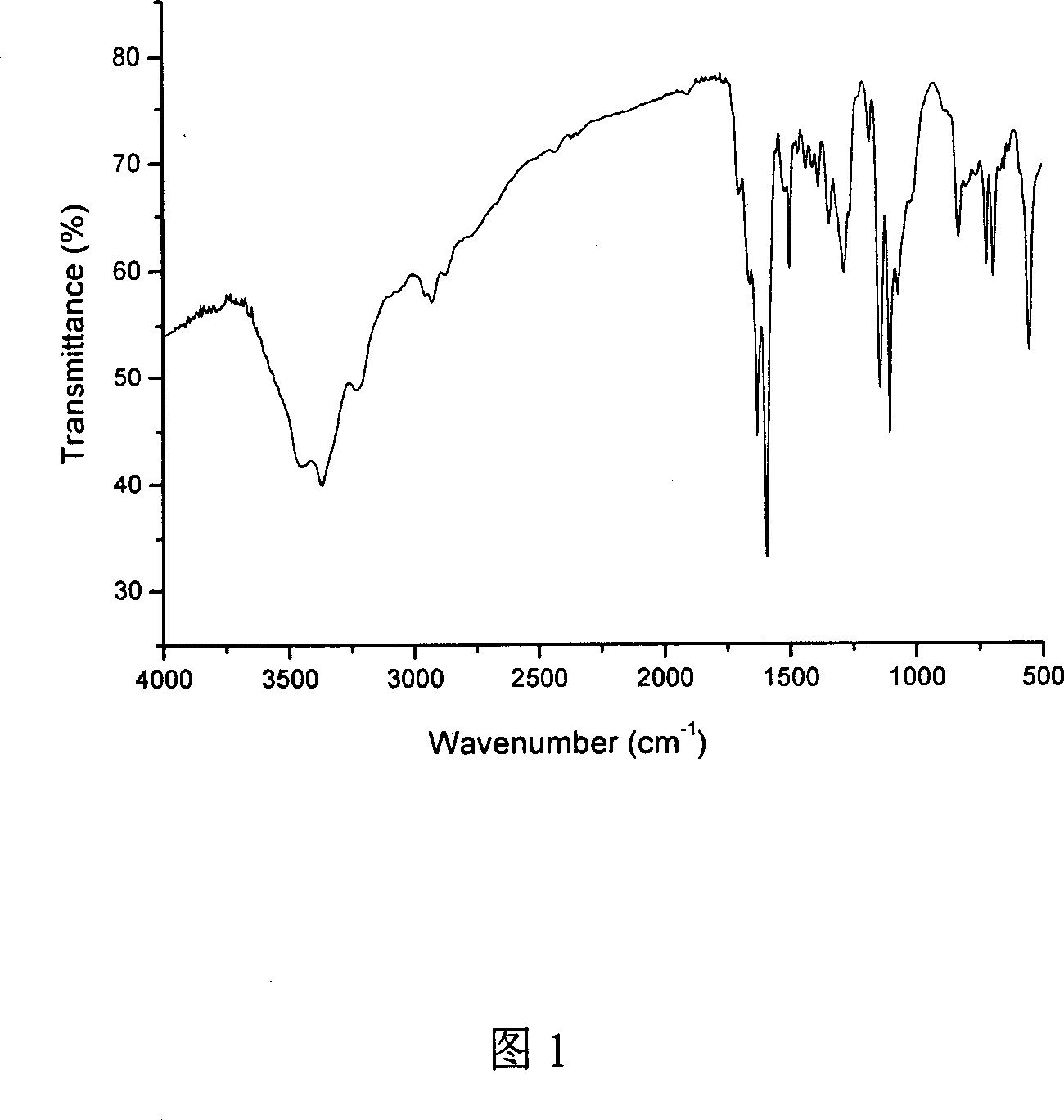

Image

Examples

Embodiment 1

[0023] Firstly, the instruments to be used in the reaction process are fully dried in an oven. Then, add the solvent dimethylformamide and 0.2 mol of 4,4'-diaminodiphenylsulfone into the three-necked flask successively, stir, and after the 4,4'-diaminodiphenylsulfone is completely dissolved, nitrogen gas is introduced, Heat slowly to 100-150°C, add 0.1mol of γ-chloropropylmethyldiethoxysilane dropwise, react at 150°C for 10 hours after the dropwise addition, distill under reduced pressure, and remove the solvent to obtain a yellow viscous liquid .

Embodiment 2

[0025] Firstly, the instruments to be used in the reaction process are fully dried in an oven. Then, add the solvent dimethylformamide and 0.3 mol of 4,4'-diaminodiphenylsulfone into the three-necked flask successively, stir, and after the 4,4'-diaminodiphenylsulfone is completely dissolved, nitrogen gas is introduced into the flask. Heat slowly to 100-150°C, add 0.1mol of γ-chloropropylmethyldiethoxysilane dropwise, react at 150°C for another 15h after the dropwise addition, distill under reduced pressure, remove the solvent, and obtain a yellow viscous liquid .

Embodiment 3

[0027] Firstly, the instruments to be used in the reaction process are fully dried in an oven. Then, add the solvent dimethylformamide and 0.2 mol of 4,4'-diaminodiphenylsulfone into the three-necked flask successively, stir, and after the 4,4'-diaminodiphenylsulfone is completely dissolved, nitrogen gas is introduced, Slowly heat to 100-150°C, add 0.1mol of γ-chloropropyltriethoxysilane dropwise, react at 150°C for 10h after dropwise addition, distill under reduced pressure, remove the solvent, and obtain a yellow viscous liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com