Glass composition for glass fiber, glass fiber, and glass fiber-reinforced resin composition using same

A technology of glass composition and resin composition, applied in the field of glass composition for glass fiber, glass fiber and glass fiber reinforced resin composition using the glass fiber, capable of solving problems such as heat generation of resin molded products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

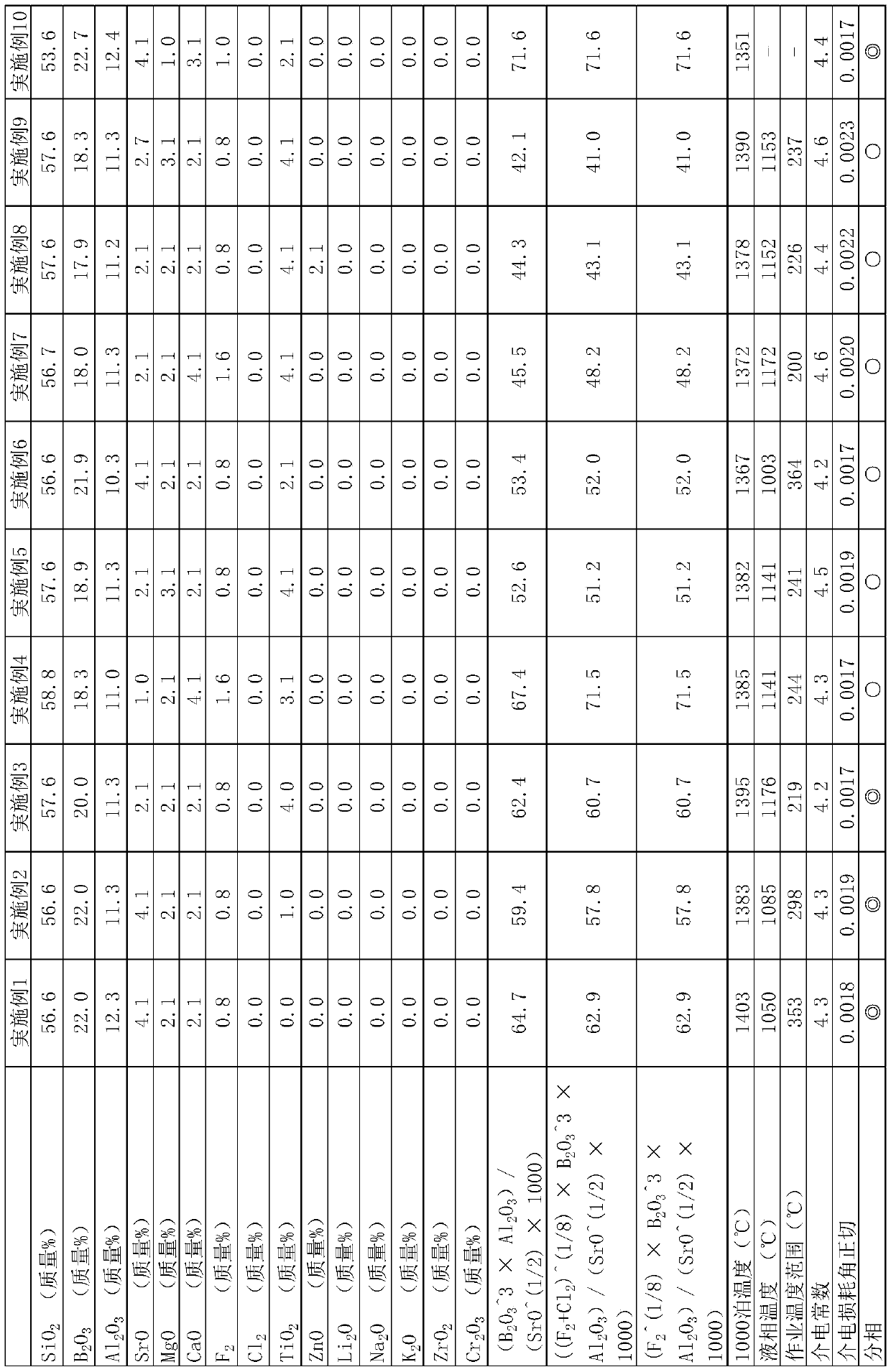

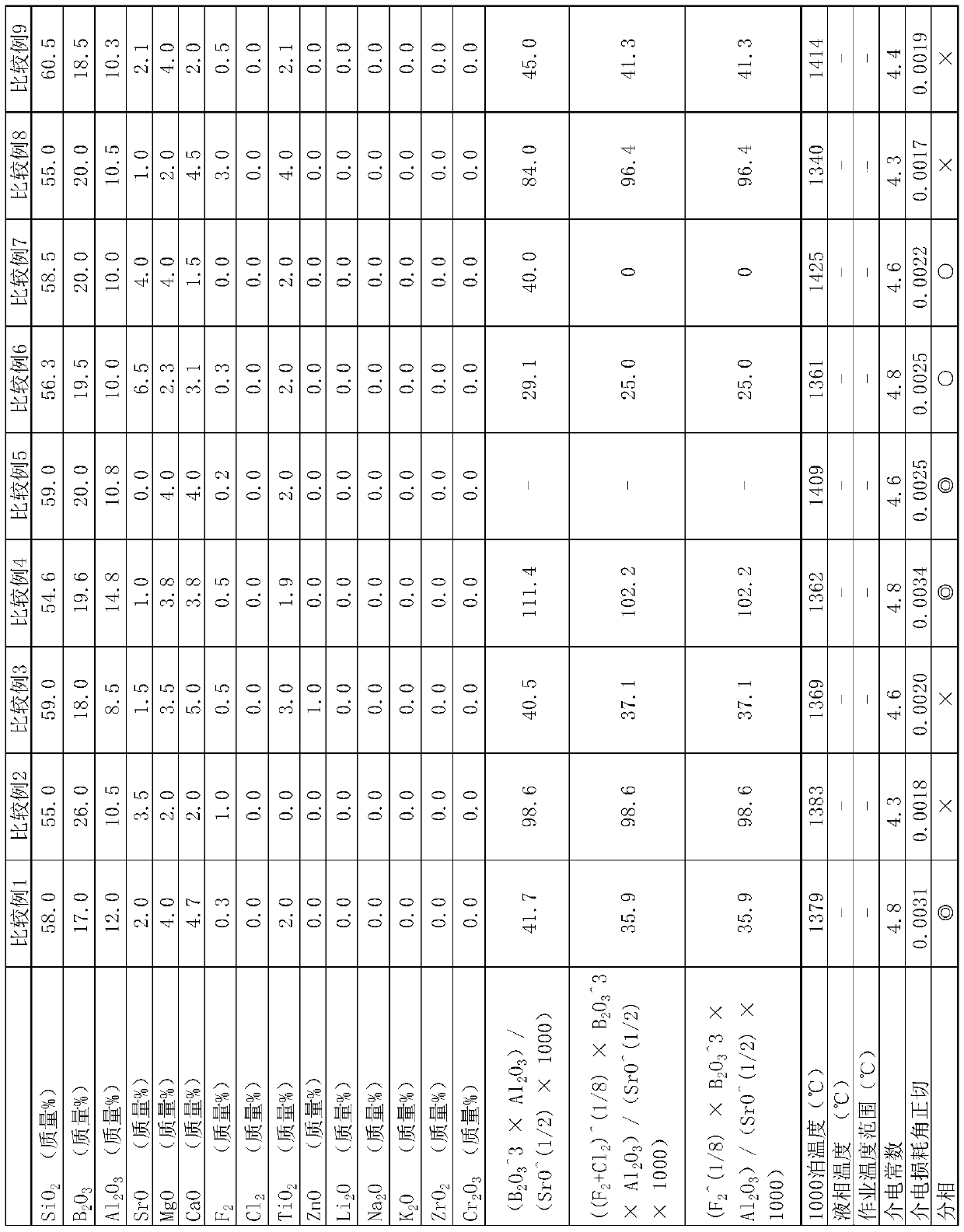

Examples

Embodiment 11

[0187] Glass raw materials were mixed so that the glass composition after melting and solidification would be the same as that of Example 1 to obtain a glass batch. The glass batch was put into a platinum crucible, kept in an electric furnace at a temperature of 1550° C. for 6 hours, and melted while stirring, thereby obtaining a homogeneous molten glass. Next, the obtained molten glass was poured out on a carbon plate, and it was set as a cullet.

[0188] Next, the obtained cullet is placed in a small cylindrical platinum bushing with a circular nozzle at the bottom of the container, heated to a predetermined temperature and melted, and then discharged from the nozzle by winding at a predetermined speed The molten glass was cooled and solidified while being drawn, thereby producing glass fibers (glass filaments) having a perfect circular cross-section and a fiber diameter of 13 μm.

[0189] As is apparent from Example 11, glass fibers can be formed from the glass composition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com