Method and equipment for preparing ultralow-loss optical fiber perform with fluorine-doped pure silicon core cladding

An optical fiber preform and core wrap technology, applied in glass manufacturing equipment, manufacturing tools, glass deposition furnaces, etc., can solve the problems of unfavorable refractive index profile, unfavorable dehydration of loose bodies, and high optical fiber water peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Example 1: Manufacturing Φ200mm×1600mm pure silicon core cladding fluorine-doped ultra-low loss optical fiber preform

[0063] (1) The material made of quartz glass is selected as the deposition target rod. Pickle the selected target rods, soak them in 10% hydrochloric acid for 1 hour to remove impurities attached to the surface of the target rods, then rinse them repeatedly with deionized water, and finally dry them.

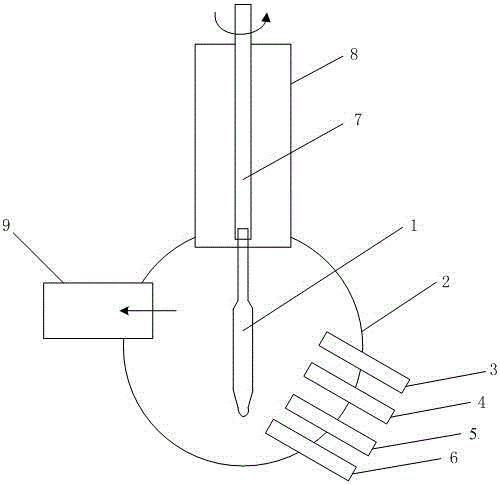

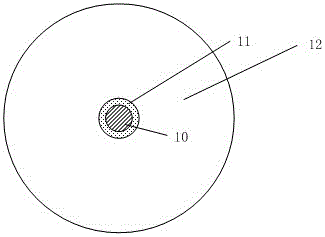

[0064] (2) Clamp the pretreated target rod on the boom hook of the VAD equipment. The mixture of silicon tetrachloride, oxygen, carbon monoxide, helium and nitrogen is used as raw material gas, and the flow rates of various raw material gases are 5g / min, 7.5L / min, 5L / min, 5L / min, 1.5L / min After the core layer of quartz material is injected into the blowtorch, the silicon dioxide particles generated by the high-temperature reaction of the raw materials in the flame are deposited on the surface of the target rod perpendicular to the blowtorch. Above the ...

Embodiment 2

[0067] Example 2: Manufacturing Φ200mm×1600mm pure silicon core cladding fluorine-doped ultra-low loss optical fiber preform

[0068] (1) The material made of quartz glass is selected as the deposition target rod. Pickle the selected target rods, soak them in 10% hydrochloric acid for 1.5 hours to remove impurities attached to the surface of the target rods, then rinse them repeatedly with deionized water, and finally dry them.

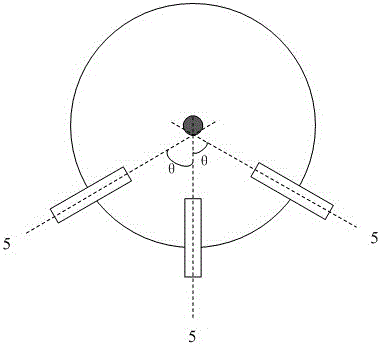

[0069] (2) Clamp the pretreated target rod on the boom hook of the VAD equipment. The mixture of silicon tetrachloride, oxygen, carbon monoxide, helium and nitrogen is used as the raw material gas. After the core layer of quartz material is torched, the silicon dioxide particles generated by the high-temperature reaction of the raw materials in the flame are deposited on the surface of the target rod perpendicular to the torch. Above the core layer, configure 3 auxiliary blowtorches with a Ɵ of 120°. Carbon monoxide and oxygen are injected into each...

Embodiment 3

[0072] Example 3: Manufacturing Φ200mm×1600mm pure silicon core cladding fluorine-doped ultra-low loss optical fiber preform

[0073] (1) The material made of quartz glass is selected as the deposition target rod. Pickle the selected target rods, soak them in 10% hydrochloric acid for 2 hours to remove impurities attached to the surface of the target rods, then rinse them repeatedly with deionized water, and finally dry them.

[0074](2) Clamp the pretreated target rod on the boom hook of the VAD equipment. The mixture of silicon tetrachloride, oxygen, carbon monoxide, helium and nitrogen is used as the raw material gas, the flow rates of various raw material gases are 5g / min, 15L / min, 15L / min, 5L / min, 2.5L / min After the core layer of quartz material is torched, the silicon dioxide particles generated by the high-temperature reaction of the raw materials in the flame are deposited on the surface of the target rod perpendicular to the torch. On the top of the core layer, 5 au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com