Method of preparing ordered mesoporous molecular sieve with high hydrothermal stability

A mesoporous molecular sieve, thermal stability technology, applied in molecular sieve compounds, molecular sieve and alkali exchange compounds, chemical instruments and methods, etc., to achieve good hydrothermal stability and avoid toxicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

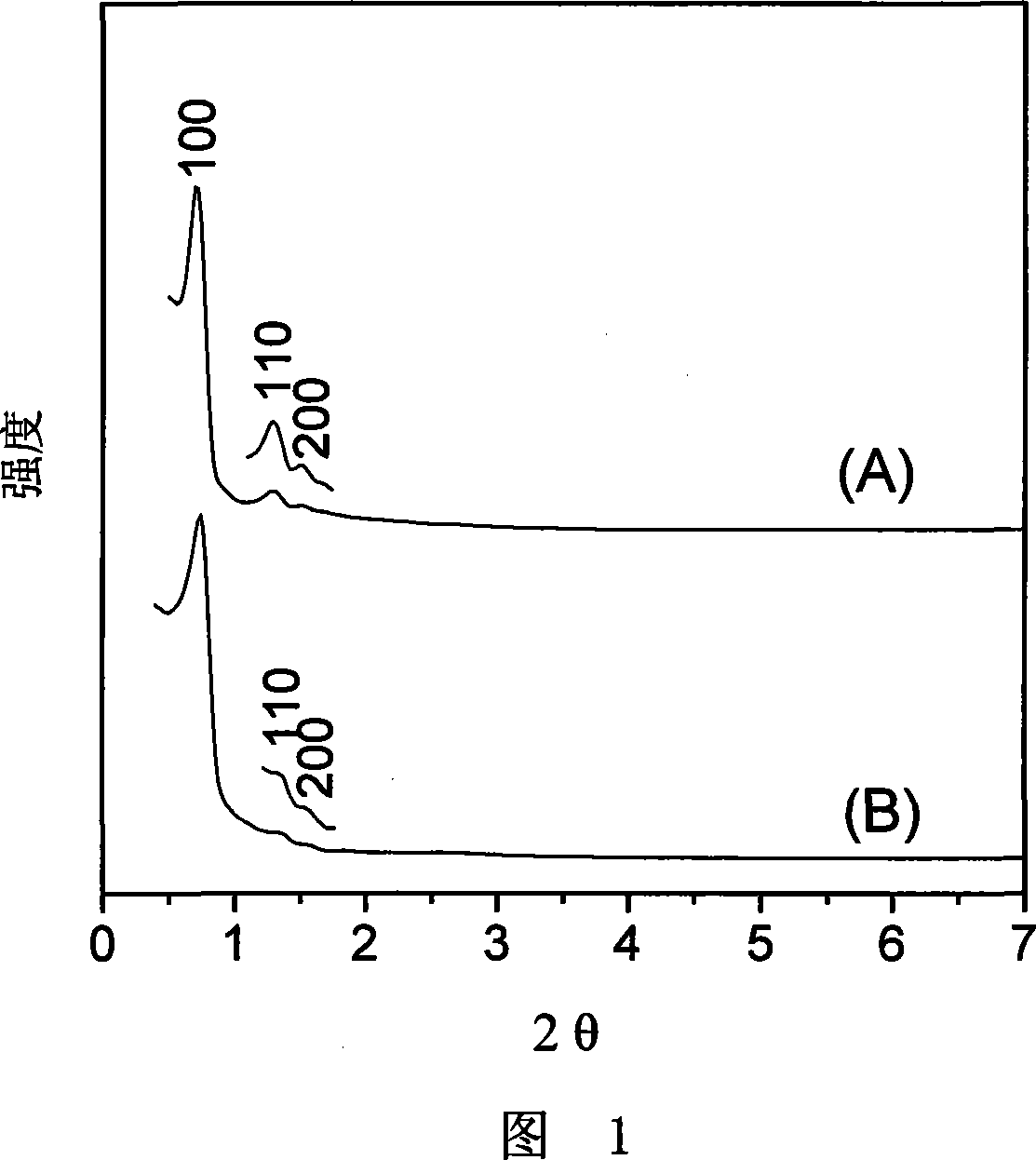

[0026] Example 1: High temperature synthesis of hydrothermally stable ordered mesoporous molecular sieve JLU-20-TEA.

[0027] Dissolve 0.4g of triblock copolymer (P123) and 0.8g of tetraethylammonium bromide in 25mL of deionized water, stir well, add 3mL of hydrochloric acid, stir until clarified, then add silicon source tetraethyl orthosilicate (TEOS) 2.08g. The above solution was stirred at 40° C. for 20 hours, then transferred to a reaction kettle, and left at 120° C. for 48 hours. The product was extracted and dried at room temperature to obtain the original powder. Raise the temperature of the original powder to 450°C in the air and keep it for 5 hours to remove the surfactant and obtain open channels.

[0028] It is also possible to carry out two crystallizations after the surfactant and the silicon source solution are transferred into the reactor, that is, standing at 100° C. for 24 hours. Then the temperature was raised to 180° C. and left for 48 hours. After calci...

Embodiment 2

[0030] Example 2: High temperature synthesis of hydrothermally stable ordered mesoporous molecular sieve JLU-20-TPA.

[0031] Weigh 0.8g tetrapropylammonium bromide (TPABr) instead of tetraethylammonium bromide, other feeding steps and treatment methods are the same as in Example 1, and the obtained product is designated as JLU-20-TPA.

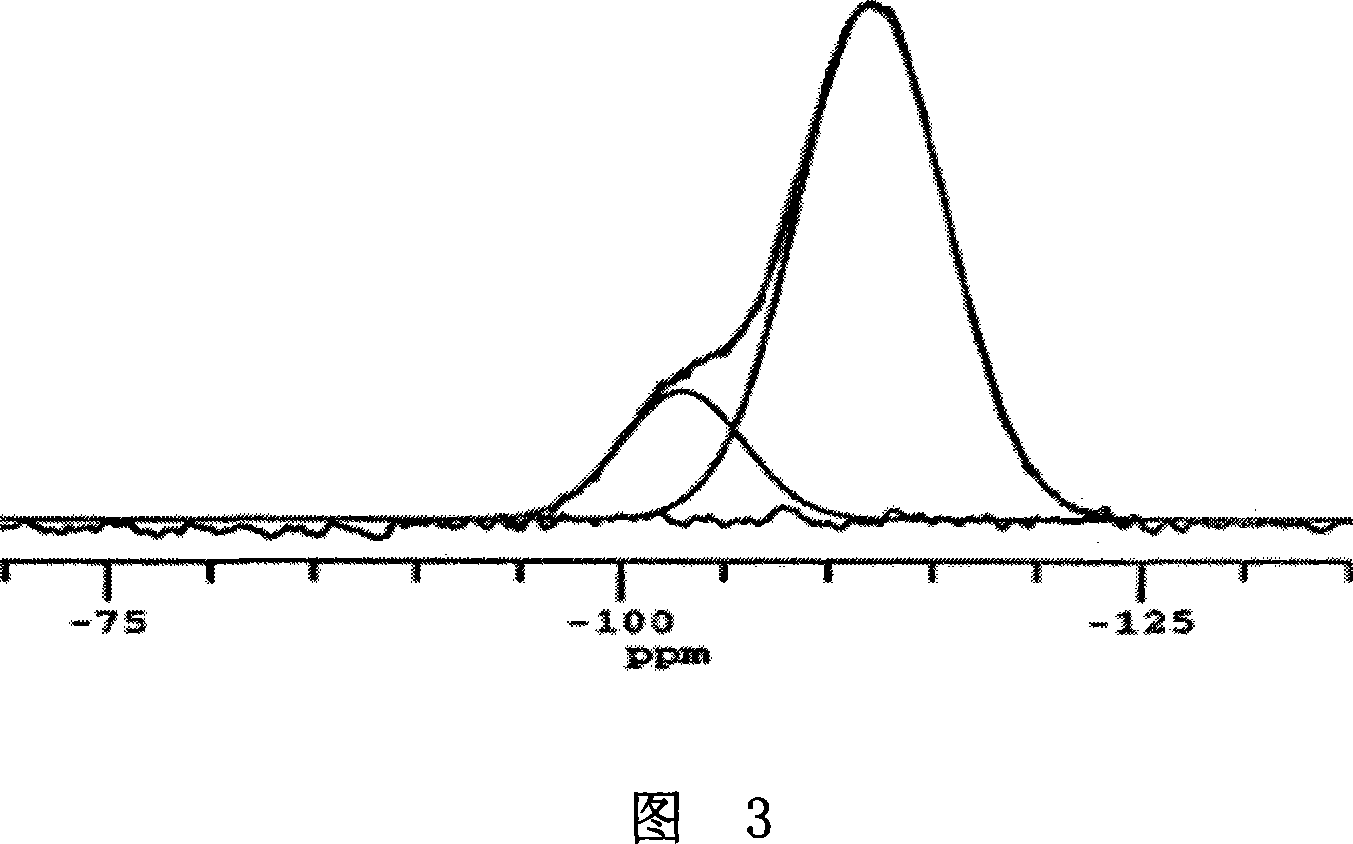

[0032] In Figure 5, A is the JLU-20-TPA obtained after calcination, and B is the JLU-20-TPA after calcination and treated with steam at 800°C for two hours. The results show that, similar to JLU-20-TEA, JLU-20-TPA is also a highly ordered mesoporous molecular sieve, and also has high hydrothermal stability. 29 Si NMR results show that in the original powder of JLU-20-TPA (Figure 6), the degree of condensation of silicon species even exceeds that of JLU-20-TEA, and the Q 4 / Q 3 The value of 4.9. These results indicate that tetrapropylammonium bromide can obtain ordered and hydrothermally stable mesoporous molecular sieves at high temperature...

Embodiment 3

[0033] Example 3: High temperature synthesis of hydrothermally stable ordered mesoporous molecular sieve JLU-20-TBA.

[0034] Using 0.8g of tetrabutylammonium bromide and hydrocarbon surfactant (P123) as a mixed template, other feeding steps and treatment methods are the same as in Example 1, and the obtained product is designated as JLU-20-TBA. The structure and performance of the product obtained are substantially the same as the JLU-20-TPA obtained in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com