Preparation method of low-hydroxyl large-diameter large-length quartz piece

A large-diameter, quartz-mass technology, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problem of unable to meet product requirements in the optical fiber field, difficult to solve the load-bearing problem of large-diameter and long quartz tube mass, unable to prepare quartz In order to achieve the effect of low hydroxyl content, high strength and high softening point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

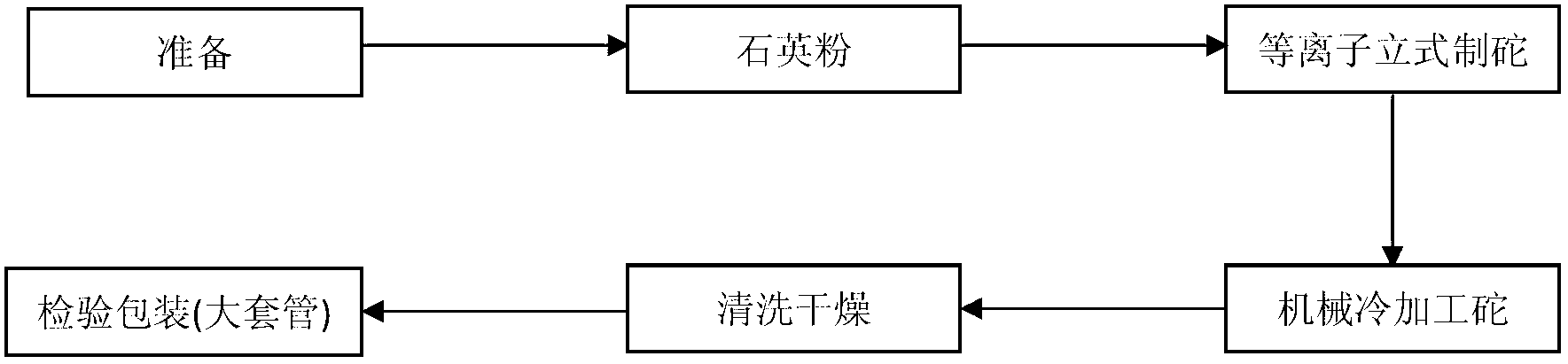

Method used

Image

Examples

Embodiment 1

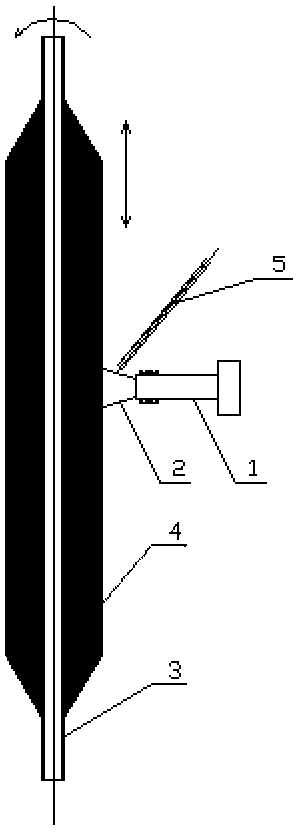

[0070] Example 1 (eg image 3 ):

[0071] Dimensions of low hydroxyl, large diameter and long length optical fiber preform quartz tube:

[0072] The outer diameter is 200mm, the inner diameter is 43mm, and the length is 1800mm.

[0073] The first step: making mounds uses the flame 2 generated by the plasma torch 1 as the heat source for melting quartz glass; Spray on the central base tube (or base rod) 3 and continuously melt into a glass state; the molten quartz glass reciprocates and rotates up and down with the center base tube (or base rod) 3 (at this time, the plasma torch 1 maintains motionless state), finally forming a hollow or solid columnar solid glass mound 7.

[0074] The plasma torch 1 is placed on the side of the central base tube (or base rod) 3 at an angle of 90° to the axis, and the central base tube (or base rod) 3 makes a vertical reciprocating motion along the axis direction, accompanied by a rotational motion ( At this time, the plasma torch 1 remains ...

Embodiment 2

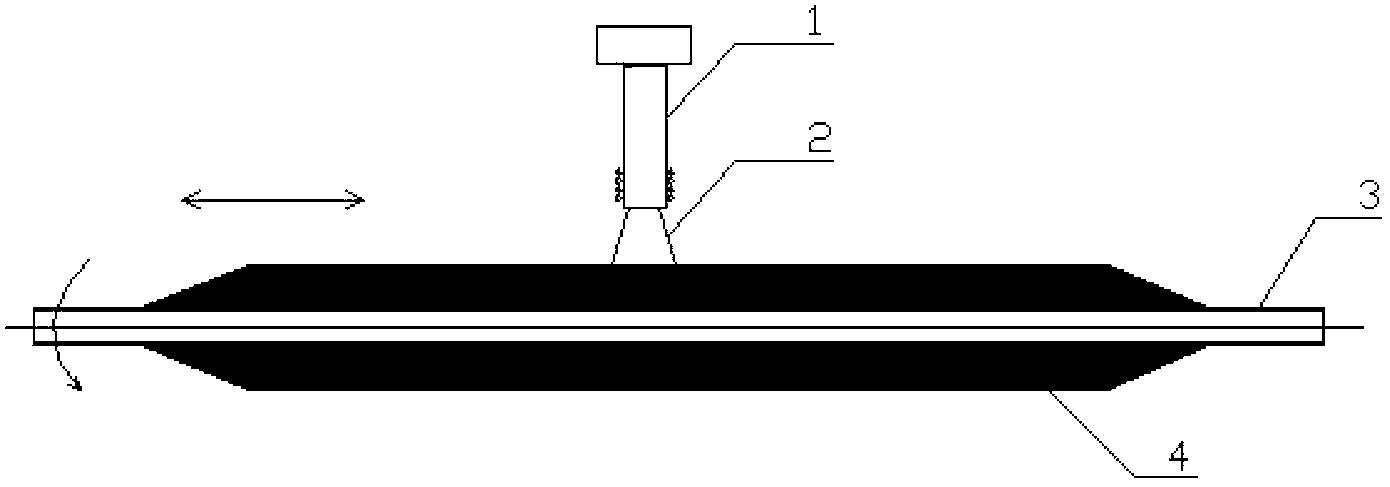

[0078] Example 2 (eg Figure 4 )

[0079] Dimensions of low hydroxyl, large diameter and long length optical fiber preform quartz tube:

[0080] The outer diameter is 220mm, the inner diameter is 43mm, and the length is 2000mm.

[0081] The first step: making mounds uses the flame 2 generated by the plasma torch 1 as the heat source for melting quartz glass; Spray on the central base tube (or base rod) 3 and continuously melt into a glass state; the molten quartz glass follows the rotation of the central base tube (or base rod) 3 and the up and down reciprocating motion of the plasma torch 1 (at this time, The central base tube (or base rod) 3 only maintains rotational motion without axial translational motion), and finally forms a hollow or solid columnar solid glass mound 7 .

[0082] The plasma torch 1 is placed on the side of the central base tube (or base rod) 3 at an angle of 90° to the axis. At this time, the central base tube (or base rod) 3 only keeps rotating, and...

Embodiment 3

[0086] Example 3 (as Figure 5 ):

[0087] Dimensions of low hydroxyl, large diameter and long length optical fiber preform quartz tube:

[0088] The outer diameter is 230mm, the inner diameter is 43mm, and the length is 2300mm.

[0089] The first step: making mounds uses the flame 2 generated by the plasma torch 1 (two plasma torches) as the heat source for melting quartz glass; Under the heating of the plasma flame 2, it sprays on the central base tube (or base rod) 3, and continuously melts into a glass state; the molten quartz glass moves up and down with the central base tube (or base rod) 3. , the plasma torch 1 remains motionless), and finally a hollow or solid columnar solid glass ingot 7 is formed.

[0090] The plasma torch 1 (two plasma torches) is placed on the side of the central base tube (or base rod) 3 at an angle of 90° to the axis, and the central base tube (or base rod) 3 reciprocates vertically along the axis Movement is accompanied by rotation (at this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com