Preparation method for phenolic resin

A technology of phenolic resin and phenol, which is applied in the field of phenolic resin preparation, can solve the problems of affecting the performance of phenolic resin, high density of resin composition, and large peeling, etc., to achieve improved moisture absorption resistance, reduced hydroxyl content, and good flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

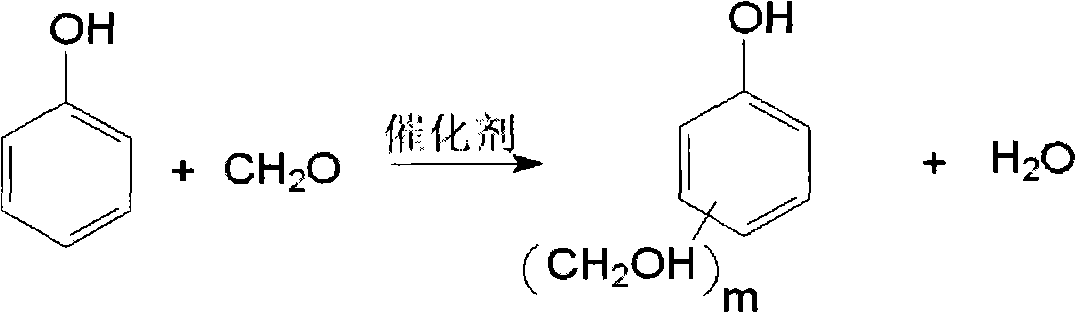

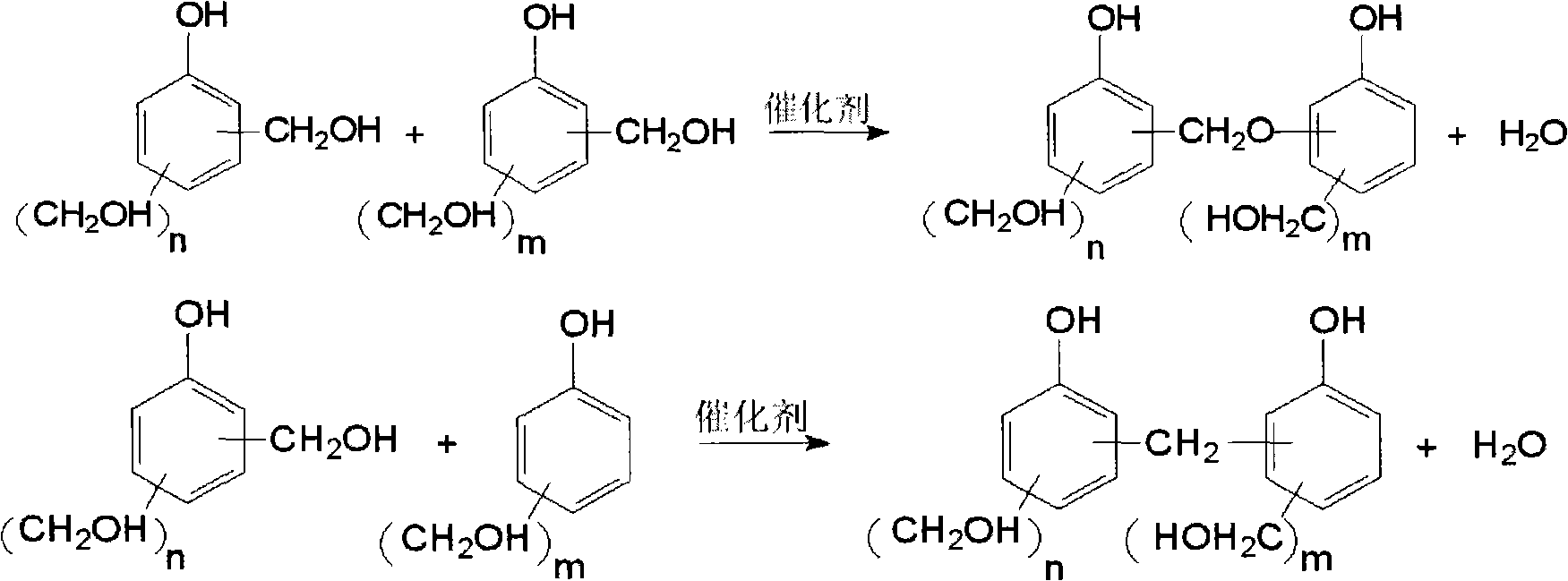

[0021] The invention provides a kind of preparation method of phenolic resin, comprising:

[0022] Phenol, formaldehyde, amino-containing organic compound and phosphorus-containing organic compound are reacted under the condition of basic catalyst to obtain phenolic resin, and the phosphorus-containing organic compound is a compound containing phosphorus-oxygen double bond, phosphorus-hydrogen bond or hydroxyl.

[0023] The present invention uses amino-containing organic compounds and phosphorus-containing organic compounds as modifiers to modify the phenolic resin during the preparation of the phenolic resin, and introduces nitrogen-containing groups and phosphorus-containing groups into the structure of the phenolic resin. The nitrogen-containing group and the phosphorus-containing group exert a synergistic flame-retardant effect, so that the obtained phenolic resin has good flame retardancy. At the same time, the amino group-containing organic compound and phosphorus-contai...

Embodiment 1

[0045] Mix 100g of phenol, 10g of melamine, 5g of triphenyl phosphite, 190g of formaldehyde with a mass concentration of 37%, and 0.5g of sodium hydroxide, heat up to 80°C, react at a constant temperature for 3 hours, and then vacuum dehydrate until the polymer viscosity is 3000cp / 25 The reaction product was collected at ℃ to obtain a phenolic resin.

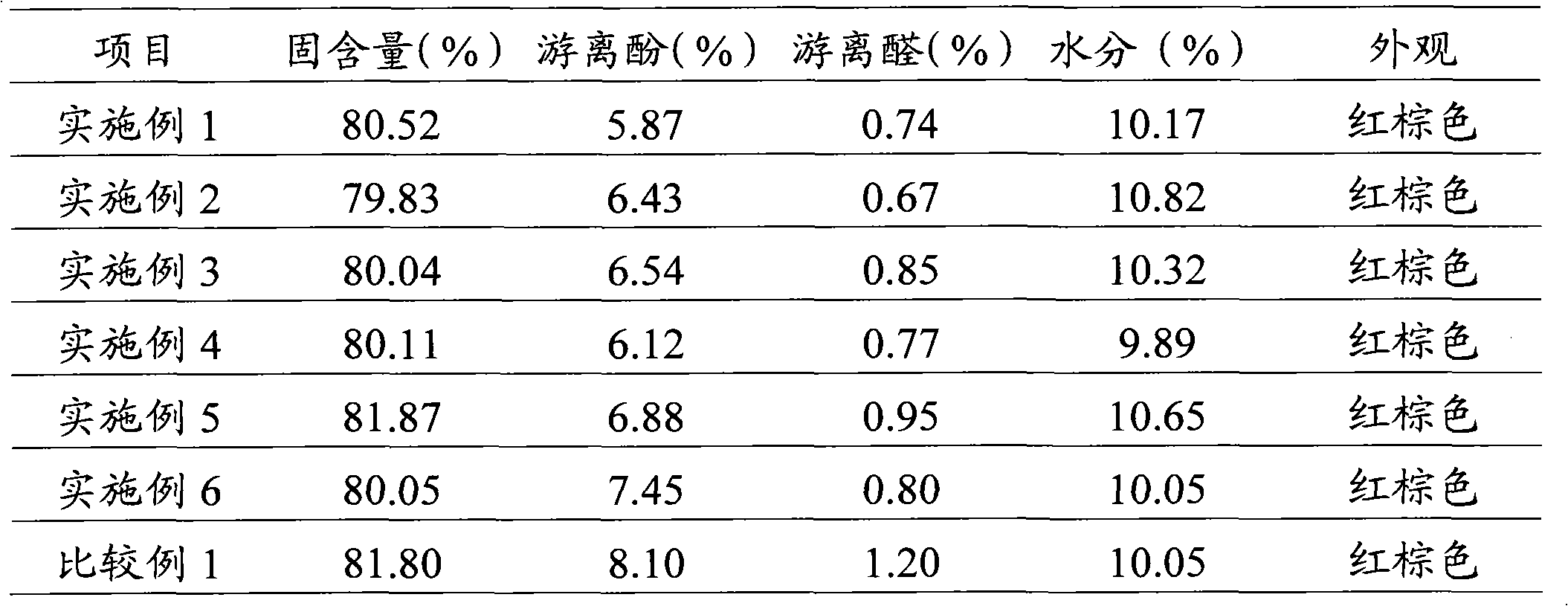

[0046] The solid content, free phenol, free aldehyde and moisture content of the phenolic resin were measured and the visual inspection results of the appearance were shown in Table 1. Table 1 shows the performance measurement results of the phenolic resin provided by the embodiments of the present invention and comparative examples.

[0047] Get described phenolic resin, take DC-193 produced by U.S. Dow Corning as a foam stabilizer, n-pentane as a foaming agent, and 70% p-toluenesulfonic acid as a curing agent to foam to obtain a foam product. The awakening density, oxygen index, thermal conductivity and water absorption were t...

Embodiment 2

[0050] Mix 100g of phenol, 15g of melamine, 10g of commercially available C9-13 hydroxyalkylene diphosphine, 190g of formaldehyde with a mass concentration of 37%, and 0.5g of sodium hydroxide, heat up to 80°C, react at a constant temperature for 3 hours, and then vacuum dehydrate to The reaction product was collected when the viscosity of the polymer was 3000cp / 25°C to obtain a phenolic resin.

[0051] The solid content, free phenol, free aldehyde and moisture content of the phenolic resin were measured and the visual inspection results of the appearance were shown in Table 1. Table 1 shows the performance measurement results of the phenolic resin provided by the embodiments of the present invention and comparative examples.

[0052] Get described phenolic resin, take DC-193 produced by U.S. Dow Corning as a foam stabilizer, n-pentane as a foaming agent, and 70% p-toluenesulfonic acid as a curing agent to foam to obtain a foam product. The awakening density, oxygen index, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com